Integrated Global Services (IGS) provides turnkey surface protection solutions that improve boiler reliability and increase plant availability. IGS’s proprietary High Velocity Thermal Spray (HVTS) cladding and SMARTGard® systems:

- Stop tube leaks

- Stop corrosion

- Reduce erosion

- Reduce slagging

- Prevent the need for panel replacement

- Eliminate the need for welding repairs

Circulating Fluidized Bed (CFB) Boiler Reliability

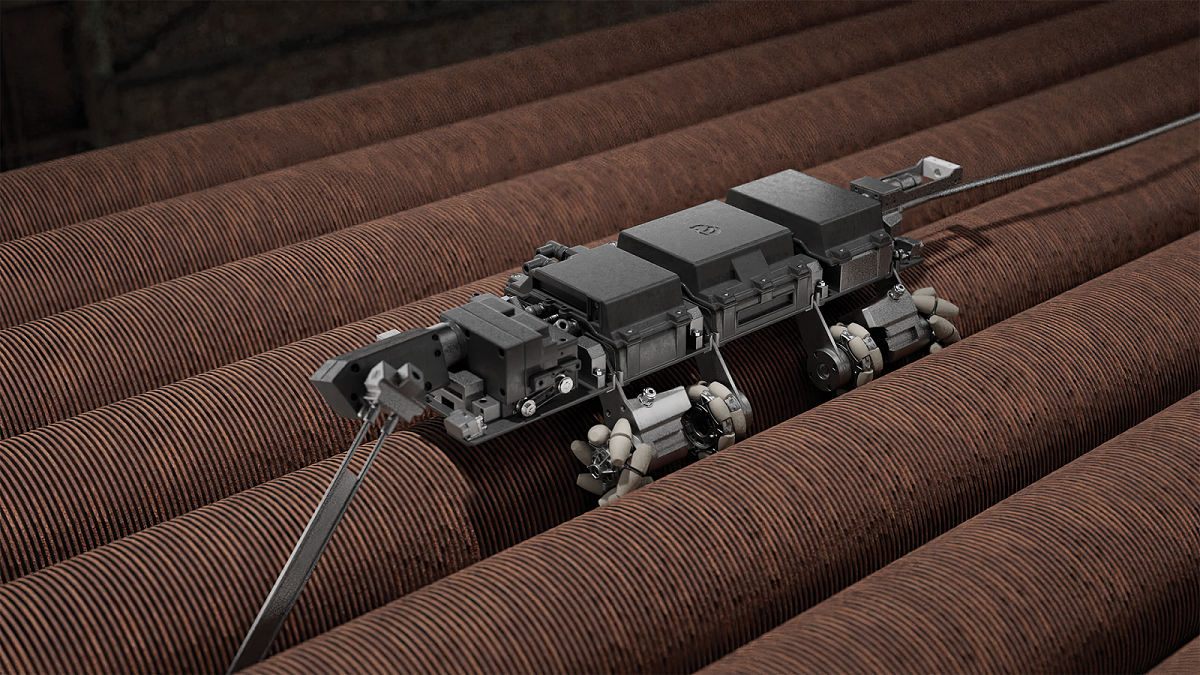

IGS leverages decades of experience with over 500 CFB boiler High Velocity Thermal Sprayed (HVTS) cladding applications to stay at the forefront of maximizing run time and minimizing outage frequency and cost for CFB boilers globally.

Waste to Energy (WtE) and Biomass Boilers

IGS provides corrosion-resistant metal alloy protection for waste incinerators, biomass, and waste-to-energy boilers. Fuel flexibility in these boilers offers related cost reduction but results in boiler corrosion. Chlorine, dew point and hot molten salt corrosion can be addressed with the application of IGS high nobility cladding.

Pulverized Coal and Lignite Boilers

With more than 25 years of applications around the world in Pulverized Coal (PC) Fired boilers, IGS has developed proven solutions to extend the life of boiler tubes providing a reliable, long-term solution with significant cost and time savings to its customers. The IGS HVTS cladding has been recognized as the gold standard to resist fireside corrosion in high-temperature sulfidation environments. As only one example, IGS HVTS was proven the best product in some of the most intense conditions in a 39,000-hour test in a 1,300 MW supercritical boiler by the Electric Power Research Institute (EPRI).

IGS’ SMART Approach to Boiler Reliability

The IGS SMARTGard® approach has been developed over four decades by working closely with hundreds of CFB operators and OEMs. What makes this solution so smart?

- S stands for systematic. Our service starts with a comprehensive boiler metal wastage assessment and considers all operational aspects of the boiler. We investigate the surface conditions thoroughly with our eyes, drones, lasers and AI.

- M stands for materials and equipment. IGS has developed proprietary equipment and alloys designed for field protection against high-temperature erosion and corrosion environments. Our cladding system works where all others fail – including high erosion, high chlorine and uneven waterwalls, among others.

- A is for application by trained and certified teams. Our experienced technicians, stationed in 15 countries, perform more than 200 days per year on shutdown and turnaround projects. No matter what your turnaround schedule is, our teams make it happen. We are proud to say that our customer satisfaction score for site execution and schedule adherence is 4.8 out of 5, surveying 113 customers.

- R is for results that are measured, documented and monitored. IGS maintains detailed records of all quality and completion documentation, initial inspection reports and all cladding thickness maps for 600+ CFB boiler projects completed. Since 2019, we have scored 4.85 out of 5 for quality commitment, surveying 226 customers.

- T is for testimonials that prove performance. Joel Taylor, Boiler Engineering and Maintenance Specialist, that has ensured reliable operation of 7 CFB boilers between 4 plants across 15 years said: “With IGS we went from a varied scope and high man hours to lower man hours and a known scope, which is great for planning for an outage, especially for the budget. Because of our process and work with IGS we didn’t need to replace pressure parts.”