TAV designs and manufactures vacuum furnaces for a range of applications, including vacuum heat treatment and brazing, vacuum sintering, and high-temperature processing of advanced ceramics and graphite.

The company’s products are used in 45 countries worldwide, in numerous industries, including the aeronautic, aerospace, automotive and tooling industries, as well as for sub-contract heat treatment and advanced research and development laboratories.

Advanced vacuum furnace solutions

The company works with customers and partners to develop new, innovative furnaces, and employs experienced engineers who use technologically advanced survey instrumentation.

The company’s vacuum furnaces can operate with vacuum levels down to the 10mbar to 7mbar range, with inert gas pressures up to 150bar and temperatures up to 2,500°C.

Customer satisfaction is guaranteed via the use of an in-house quality system, which has been in use since 1998.

Vacuum heat treatments

TAV’s vacuum heat treatment can be applied to steels, super alloys and titanium alloys, among other materials. This process produces high-quality metallurgical results, giving the material a bright surface.

Heat treatment furnaces can be used with the following:

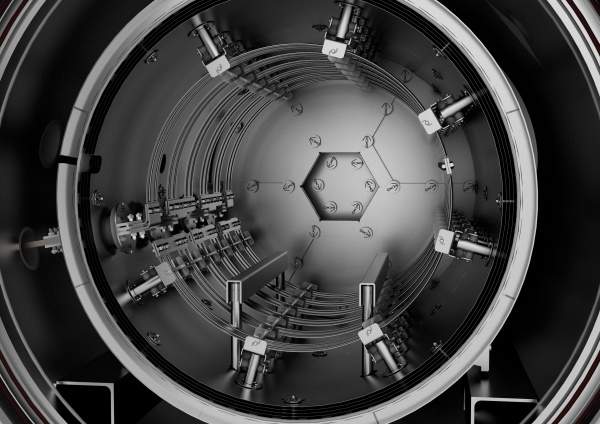

- Single or multiple pumping groups

- High vacuum systems, including cryogenic traps and all dry pumping groups such as claw, screw, turbomolecular and cryogenic pumps

- Graphite / carbon fibre composite (CFC) or all metal chambers that operate in temperatures up to 1,400°C

- Gas convection assisted heating

- High-pressure gas quenching systems with multidirectional, controlled gas flow configurations

- NADCAP compliant control systems with PC-based supervisory control and data acquisition (SCADA), overall equipment effectiveness (OEE) and performance measurement features

Vacuum brazing for increased heat speed and reduced cycle time

TAV’s vacuum furnaces can be used for a range of vacuum brazing purposes. These range from the brazing of copper, nickel and stainless steel to nickel brazing of aero-engines and IGT components.

Furthermore, stainless / ceramic brazing, aluminium brazing and titanium brazing can also be performed.

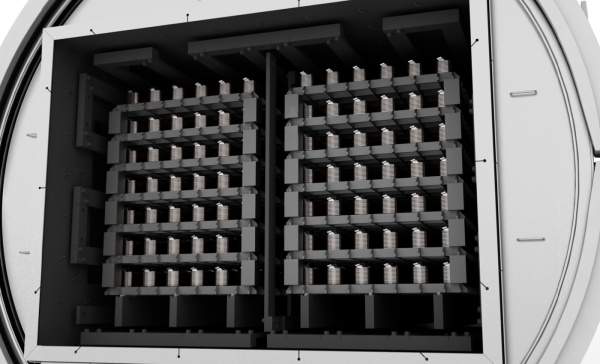

To increase heat speed and reduce cycle time, convection assisted heating properties or single or multiple loading zones can be applied to the company’s furnaces for stainless-steel heat exchangers.

Stainless-steel vacuum sintering

TAV provides stainless-steel sintering at approximately 1,250°C. The thermic chambers can be graphite or metal, while the sinter-hardening processes are made possible by high-cooling gas pressure.