SootTech provides systems to optimise the performance of power and recovery boilers with its high-impact soot system (HISS) sootblowing solution.

SootTech is a subsidiary of CleanTech. It was founded in 2007 to focus on the development of innovative HISS sootblowing, by Chalmers Innovation and industrial innovator Erik Dahlén.

Since being established, SootTech has quickly progressed from its prototype installation to a worldwide supplier of sootblowing technologies for optimising recovery and power boilers.

High impact soot systems for sootblower efficiency

When generating power, every megawatt hour is important. Efficiency can be improved through regular sootblowing.

Sootblowing technology provided by SootTech ensures that boilers are kept clean for optimising burn efficiency in producing electricity and heat.

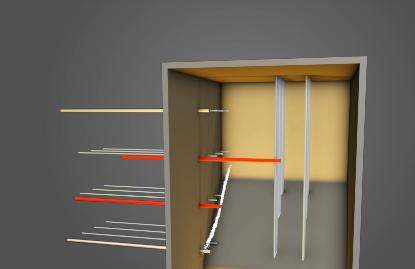

The company’s HISS allows for the operation of several sootblowers at once, which increases sootblowing and ash removal, while decreasing the amount of steam.

High impact soot systems can halve:

- The amount of steam consumed through sootblowing

- The delays caused by disruptions

- The time heat surfaces are exposed to steam

Increasing efficiency of sootblowing in superheaters

The burning of lesser quality fuels causes substantial problems for coatings.

Corrosion is often caused by ash clogging up the rear superheaters and creating higher temperatures.

In order to keep flue gas temperatures lower, it is necessary to increase the amount of sootblowing in the superheaters, which also helps stop the ash from forming on the tubes and causing blockages.

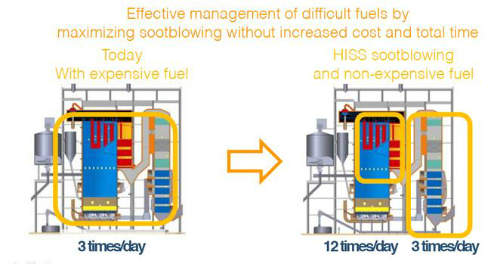

Due to HISS reducing the time required for sootblowing, the process can be quadrupled without increasing its cost or duration.

The technology enables a simple and natural method of fuels that are cheaper and more volatile.

With many boilers, the load in the furnace needs to be decreased when sootblowing is taking place so that it is possible to deal with the increased amount of flue gas that has been caused by sootblowing.

Reducing corrosion in boiler tubes

The erosion of tubes during steam sootblowing is a regular problem when using standard technology; it is caused by jets of steam causing sharp particles in flue gas to significantly accelerate and blast into the tubing. This damage causes costs to spiral through necessary repairs and slows down production.

SootTech’s HISS technology halves the time sootblowers are exposed to steam, but still results in the same results in soot cleaning.

In addition, when burning waste fuels, the amount of chlorine in ash is increased. Longer operating times between sootblowing sequences concentrates the amount of chlorine in the ash, which reduces the sticky temperature and increases corrosion.

A recommended method for dealing with corrosion on cold heat surfaces is to carry out sootblowing processes more frequently, which is achieved through HISS technology without increasing the time taken or increasing steam consumption.

Optimising sootblower economisers

With electricity prices continuing to soar, it is essential that a recovery boiler operates at its optimum level to produce a sufficient level of power.

The efficiency of the surfaces of the economisers has a direct impact on the amount of steam energy produced. During this process, sootblowing is also regularly diverted from economisers due to blockages earlier in the flue gas direction.

With SootTech’s HISS technology, heat absorption in megawatt levels is simply increased through cleaning the surfaces of the economiser more thoroughly without any rise in soot steam used or the flue gas volume.

In HISS electricity mode, sootblowing is easily redistributed and electricity production is increased.