Selnikel is the most experienced company in Turkey in the design and manufacture of:

- Water tube steam and hot water boilers

- Fluidized bed coal fired boilers

- Fire / smoke tube steam and hot water boilers

- Waste heat recovery boilers

- Industrial fans

- Industrial burners

- Pressure vessels

- Combustion management systems

The company operates in line with international standards and ensures the quality of its products and services by the certificates of compliance to ISO-EN; ASME; CE; TUV, TSE, Lloyd, ISCIR, Ghost, Sepro, etc.

Selnikel carries out turnkey projects in Turkey and abroad, including the design, manufacture, installation, commissioning and after-sales services of boilers, HRSGs, burners and combustion management systems tailored to the needs of its clients. Furthermore, centrifugal fans are provided for almost all industries requiring air / gas flow in clean or dirty environments.

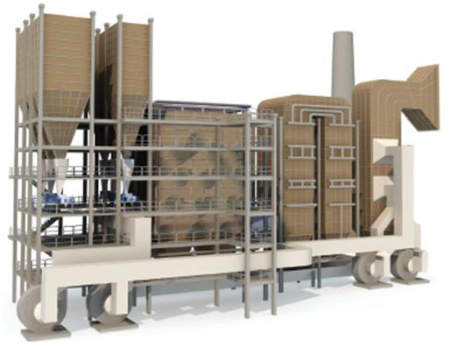

High capacity water tube steam boilers

Production ranges from 25t/hr up to 150t/hr steam boilers with high pressure levels for all types of fuels ( natural gas, fuel-oil, biomass, biogas, etc.) Selnikel is a licensee for Erk Eckrohrkessel corner tube boilers, which differ basically from other boiler types by several characteristic features like a self-supporting frame system, quick start-up, low pressure variations at turndown, high steam purity, and single drum structure.

Designs are carried out as per EN 12952 or ASME Section I with a boiler efficiency of 94%. Boilers may be floor mounted, packaged or field erected with superheater, economiser, multiple burners for increased capacity, special design of drum internals for high steam purity, membrane / studded walls, water-cooled furnace construction, fine combustion control and high turndown ratios.

Fluidized bed coal fired boilers

The bubbling fluidized bed combustion technology introduced by Selnikel in cooperation with EckRohrKessel GmbH-Germany is a perfect system for burning low calorific value coals in an economical and enviroment friendly way with 99% burning efficiency, low NOx and SO2 emission levels. Production ranges from 6t/hr up to 50t/hr steam boilers with high pressure levels.

Fire / smoke tube steam and hot water boilers

Shell type fire / smoke tube boilers whose tubes carry flue gases which are surrounded by the boiler water in the shell, are designed and manufactured for capacities from 1t/hr to 30t/hr steam production up to 25 bar pressure and 0.4kW to 15MW hot water production. Boilers are three-pass type with rear flue gas reversing chamber for optimum heat recovery, easy access for inspection and cleaning, lowest operating cost coupled with trouble-free operations and long life.

Furnace design is straight or corrugated with proper volume for efficient combustion and burning of the fuel. Boiler design is according to EN 12953 or TRD 403.

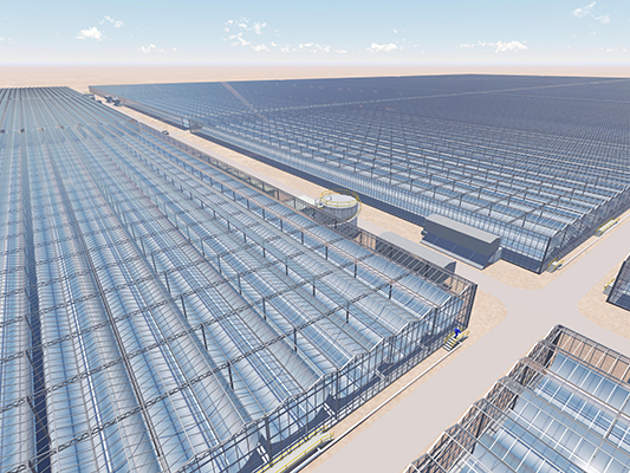

Waste heat recovery boilers

Selnikel handles the complete design, manufacturing, installation and commissioning of water tube or smoke tube, single-pass or double-pass waste heat recovery boilers up to 60 bar pressure and 150t/hr steam production capacity for cogeneration systems, glass ovens, cement factories, and similar industrial plants.

Boilers have a natural circulation design for higher reliability, availability and lower power consumption, equipped with supplementary firing, bypass stack, economiser, etc. depending on the requirements.

Industrial centrifugal fans

Selnikel manufactures single or double inlet, exproof centrifugal fans for clean air or flue gas exhaust up to 3,500mm WG pressure and 850,000m³/hr air capacity.

Seven different series with 23 different impeller types for cement, glass, steel, paint, chemicals, wood, pharmaceuticals, paper, tobacco, textile, etc. industries for all environments, from clean to sticky and wet to dusty, are available.

Boiler house components

Any auxiliary equipment for the heating centres, such as feed water tanks, deaerators, shell and tube heat exchangers, pumping stations, storage tanks, piping systems for water, oil or gas, etc., are designed, manufactured, installed and commissioned by Selnikel.

Pressure vessels

Selnikel designs and manufactures columns, towers, tanks, vessels for petrochemical plants, process equipment, etc. as per ASME Section VIII, Division I with ASME ‘U’ Stamp.

Combustion management system and integrated automation module

Maximum efficiency and reduced emissions have been ensured for all Selnikel boilers through burner controls which enable users to achieve significant fuel and emission savings over conventional systems.

Selnikel is the authorised dealer of Autoflame combustion management systems in Turkey. The Autoflame MM system enables the position of fuel valves and air dampers to be precisely controlled to 0.1% accuracy, ensuring combustion efficiency is optimised at all firing rates. Where coupled with an exhaust gas analyser (EGA) all Autoflame burner controls will carry out three parameter combustion air trim. The system will make minor adjustments to the combustion air damper or variable speed drive controlling a forced draft fan to counteract the reductions in efficiency caused by variations in barometric conditions, stack pressure, etc.

After-sales services and customer support

Selnikel provides continuous supervision, commissioning, maintenance, spare parts supply services for its products all over the world.

For critical applications requiring an enhanced level of support, we offer a 24 hour service level agreement option. Through Autoflame’s data transfer interface module we are able to monitor boilers remotely and respond to issues in some cases before services are affected.