Outotec energy solutions include technologies and services for renewable and conventional power generation.

Outotec energy solutions include technologies and services for renewable and conventional power generation.

Tailored lifecycle solutions cover every part of the process, from plant design and implementation to ongoing operational support, maintenance and modernisation.

The result for the customer is a sustainable renewable energy solution with optimised total cost of ownership, minimised equipment downtime, and increased production efficiency over the lifecycle of the plant.

Delivery scope can cover the entire process chain from fuel to energy. Outotec can provide the fluidised bed technology, the boiler island, or the entire power plant as a complete turnkey delivery. More than 120 waste-to-energy plants have been commissioned worldwide so far.

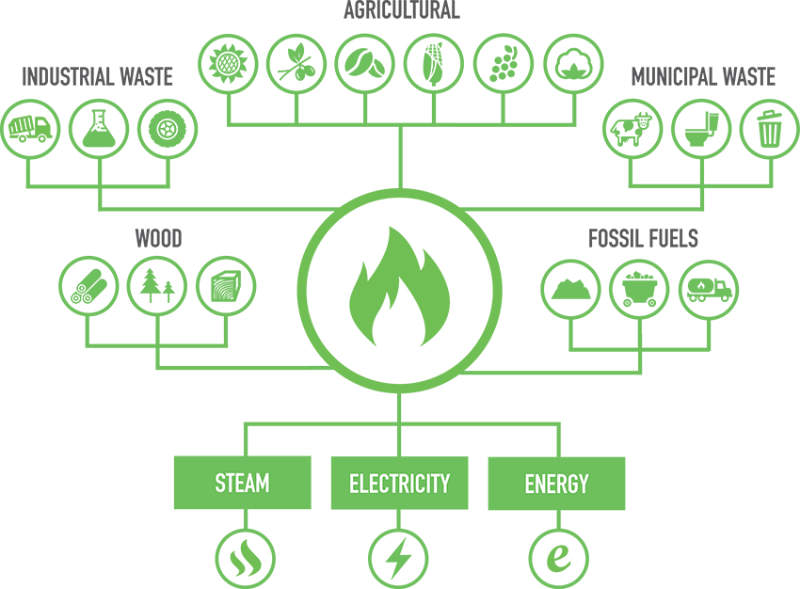

Fuel flexibility for greater operational flexibility

More than 250 different fuels have already been used in Outotec fluidised bed solutions, including agricultural, municipal solid and wood waste, as well as industrial / municipal sludge, plastic, and tyres. This ensures greater operational flexibility and eliminates the risk associated with reliance on a single supplier or fuel type.

Sewage sludge incineration plants

Outotec’s advanced fluidised bed sewage sludge incineration plants are self-sustaining and do not involve external fuel sources when in continuous operation. This is made possible by sludge pre-treatment and preheating of combustion air.

The incineration plants meet the strictest global emission standards and are designed to treat sewage sludge from cities and communities of other sizes. They produce a surplus of electricity or heat that can be used in industrial or district heating. Sewage sludge ash treatment applications are also provided.

Bubbling fluidised bed (BFB) boilers and advanced-staged gasifiers

Outotec bubbling fluidised bed boilers use various fuel sources and are capable of efficiently combusting fuels of varying consistencies.

The advanced-staged gasifier uses optimised technologies to generate steam and is suitable for fuels with low ash-softening temperature due to lower furnace heat.

The company’s bed material drawdown and recirculation equipment eliminates disturbances in the area by removing small build-ups, even at low bed temperatures.

Circulating fluidised bed (CFB) boilers and gasifiers

The Outotec circulating fluidised bed (CFB) boiler and CFB gasifier use a wide range of primary fuels, including coal and organic matter (biomass).

The CFB system reduces costs by enabling the co-firing of low and high heating value fuels such as waste materials, sludge, and refuse-derived resources. It is also possible to use petroleum coke and coal because of the unit’s robust design.

Plants usually achieve low-emission levels without additional flue-gas cleaning due to the low combustion temperatures in CFB boilers.