Babcock Power is a group of companies offering unparalleled expertise — more than 400 years of combined experience in engineering, manufacturing, construction, and aftermarket products and services — for heat exchangers, heat recovery steam generators (HRSG), boiler air pollution control systems, and steam generators with associated fuel preparation (pulverizers) and firing systems.

We provide complete solutions for any OEM’s equipment for the global power generation, industrial, environmental, and waste-to-energy markets. These include boiler services, feedwater heaters, low NOx burners, moisture separator reheaters (MSR) and surface condensers among others.

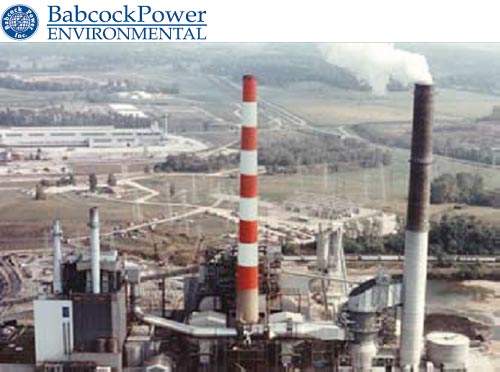

Babcock Power Environmental — boiler air pollution control systems

Babcock Power Environmental (BPE), along with its affiliate Riley Power, (both based in Worcester, MA) provide fully integrated environmental solutions for utility power plants, waste-to-energy facilities, and large industrial applications.

BPE’s integrated line of products and services provide clients a single source for the removal of SO2, NOx, HCI, SO3, mercury and fine particulates.

BPE has more than 40 years of experience with boiler air pollution control systems, and is a market leader in the field of environmental air pollution control technology. The company has more than 34,000MW of selective catalytic reduction (SCR) systems being designed, under construction or operating in the USA, and a reference list of over 65,000MW worldwide.

BPE’s technology base for wet and dry flue gas desulphurization scrubbers for the removal of SO2 also exceeds 60,000MW worldwide.

Babcock Power Services (BPS) — boiler services for fossil-fired power plants

BPS, based in Worcester, MA, is a leading supplier of technology, equipment, engineering and boiler services for upgrading and maintaining fossil-fired steam generating plants. BPS draws upon the strengths of a group of industry-recognized companies, including OEM Riley Power, Boiler Tube Company of America (BTA), and TEi Construction Services.

BTA has supplied replacement boiler components for all styles of boilers to the electric utility, pulp and paper, waste-to-energy, petrochemical, marine, sugar and grain industries since 1918.

Riley Power has been designing and manufacturing fuel firing equipment including steam generators, low NOx burners and pulverizers for all types of fossil-fired and waste-fuel-fired plants for over 90 years.

TEi Construction Services is an open-shop contractor who provides direct hire construction services to the utility and industrial markets in the US and Puerto Rico. The boiler construction services supplied are: installation and repair of steam generators, including air heaters, ductwork, insulation and lagging, boilers, burners, baghouses, precipitators, surface condensers, feedwater heaters, and general boiler services.

Thermal Engineering International (TEi) — feedwater heaters, surface condensers and moisture separator reheaters

TEi (USA), based in Santa Fe Springs, CA, is a leading supplier of heat transfer technology to the electric power-generation industry. TEi offers fully-integrated design, engineering, manufacturing, research and development, construction and service capabilities.

Formerly Southwestern Engineering — and most recently Senior Engineering — TEi has been designing and fabricating surface condensers, feedwater heaters, power-plant heat exchangers and moisture separator reheaters (MSR) for the world’s power generation industry continuously for over 90 years.

TEi Struthers Services, a division of Thermal Engineering International (USA), provides a full range of aftermarket heat transfer products and boiler services to the utility, petrochemical, industrial, pulp and paper, and metal processing industries.

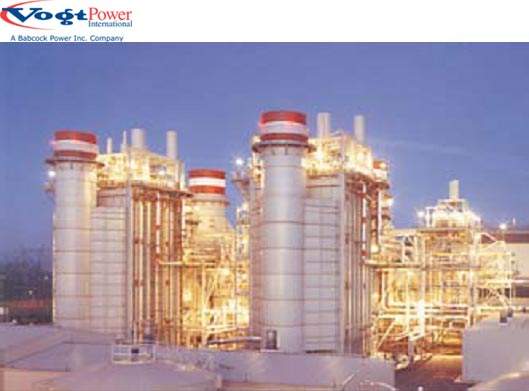

Vogt Power International (VPI) — heat recovery steam generators (HRSG) and boiler services

VPI, based in Louisville, Kentucky, US, specializes in the design, manufacturing, and supply of HRSG and aftermarket related services. VPI is an industry-leading HRSG manufacturer with unequaled experience in combined cycle and cogeneration plants. VPI’s extensive experience includes supplementary and auxiliary-fired units, the supply of SCR and CO systems, and additional design features such as stack dampers, silencers, shrouds, and exhaust bypass systems.

VPI’s aftermarket services provide efficient, cost-effective solutions for any OEM’s HRSG. Experienced engineers, inspectors, project managers, and construction advisors create a single-source solution provider.