Non-metallic expansion joints (NMEJ) offer a number of advantages, especially in plant design and building. They take up movements in several directions simultaneously, have almost no reactive forces, need little space for installation, are easy to adapt to existing physical conditions, and are easy to transport and install.

NMEJ are designed on the basis of:

- Thermal movements in the duct system

- Design values of the medium temperature and pressure

- Composition and nature of the medium flowing in the ductwork

- Gas velocity

- Dust content in the medium

- Special requirements with regard to the installation

- Space availability

Each NMEJ is custom-built to suit the application in question with regard to:

- The temperature ranging from -65°C to 1,400°C

- Choice of material and composition

- Fastening or tightening method

- Steel part and steel quality

- Insulation (bolster)

- Mechanical protection against abrasion (sleeve arrangement)

- Fabric expansion joint alone or pre-assembled on steel parts (units)

- Additional mechanical protection to the fabric from the outside

These NMEJs can be manufactured (against order) in all the necessary shapes and forms according to customer requirement viz. round, rectangular, square, oval, conical or combinations in different configurations shown below.

All fabric can be supplied as fabric part only or pre-assembled on steel parts for quick installation in the duct system.

KELD Uniflex

This variety includes a range of single layer expansion joints, consisting of specially developed materials, which cover a temperature range of -65°C to 200°C.

KELD Flexfab

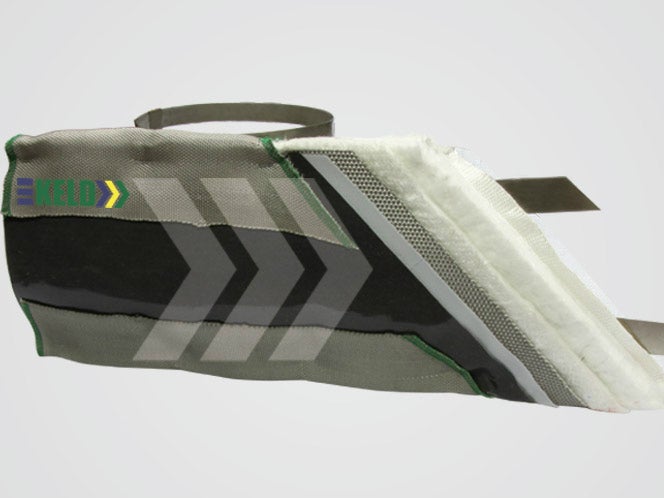

This series includes a range of multi-layer expansion joints, covering most operating conditions in air or gas duct systems. The individual type of expansion joint is chosen on the basis of the chemical composition of the medium, maximum operating temperature etc. KELD Flexfab series can be supplied with or without a membrane, which is impervious and resistant to chemicals. Similarly, the type of outer cover can also be varied depending upon the operating and customer requirement.

KELD Cemfab

This series includes a range of products developed exclusively for the cement industry. The special feature of this series is its outer cover, which provides mechanical protection to the fabric expansion joint.

KELD Flexfab-SB

This series is generally used only when the application temperature is very high (beyond 750°C) or the application demands a special pre-formed fabric expansion joints.

Special applications

KELD has also specialised in the following applications for expansion joints:

- Diesel generator exhaust ducts

- Babcock coal mills

- Chimney seals for multi-flue chimneys

- Pipe penetration joints in HRSG

- Reformer tube expansion joints

- Repair of damaged metallic expansion joints