STROS – Sedlčanské strojírny has half a century of engineering experience and specialises chiefly in access equipment. You can find our products on building sites all over the world, from the Arctic Circle to the tropics, from the US to Singapore.

We design, manufacture, install and service personnel / material hoists, special and permanent elevators, suspended platforms, material hoists and work platforms. Our products are high-quality, reliable and respected worldwide. Our customers also appreciate our first-class warranty and after-sales service, as well as supply of spare parts.

Personnel / material hoists

STROS personnel / material hoists offer a complete range of mechanisms for the transport of passengers and materials. The cage is welded with quality steel profiles, and the side walls are covered with aluminium sheeting and steel wire mesh or Perspex. The access and exit doors slide vertically and their closing is checked electronically. They are also mechanically blocked and can only be opened when the cage is at a landing.

The drives of all STROS personnel / material hoists can be equipped with a frequency converter, which improves the ride qualities and levelling precision. Thanks to smooth starts and stops, lifting speeds of up to 100m/min can be achieved.

The safety device is designed to safely stop the machine if the nominal speed in the down direction is exceeded. The safety heart of this device is a centrifugal mechanism, which is individually and accurately set for a particular machine model.

The control systems are available as single automatic or selective / collective. Single automatic operation allows control of the elevator from the cab and landings. Calls are answered one at a time. Selective / collective operation allows control of the elevator from the cab and landings. Calls are collected and answered in the most efficient manner relevant to direction.

Special-purpose industrial elevators

STROS special-purpose industrial elevators are primarily used as service elevators for the vertical travel of personnel and material. The advantages of STROS special-purpose industrial elevators include easy installation, achievability of great lifting heights, easy implementation of structural modifications in the place of installation, and no need for an enclosed shaft. Our delivery includes engineered installation drawings, operating documentation and test certificates.

The quality and durability of our special-purpose industrial elevators has been proved through reliable operation and long lifecycles in harsh industrial environments such as refineries, cement plants, lime kilns, power plants, coal handling facilities, steel mills, mines and offshore facilities. Our equipment is also well-suited for any location where conventional traction or hydraulic elevators are impractical to install.

Customised elevators for power plants

Thanks to the efforts of the team of designers, STROS ensures continuous development and innovation of its products. The company supplies customised elevators, e.g. for:

- Power plants

- Cement plants, lime kilns, gravel pits, etc.

- Steel plants

- Refineries, oil tanks

- Warehouses, towers, etc.

STROS also supplies elevators that are designed to transport personnel and materials underground (e.g. for the maintenance of electrical networks).

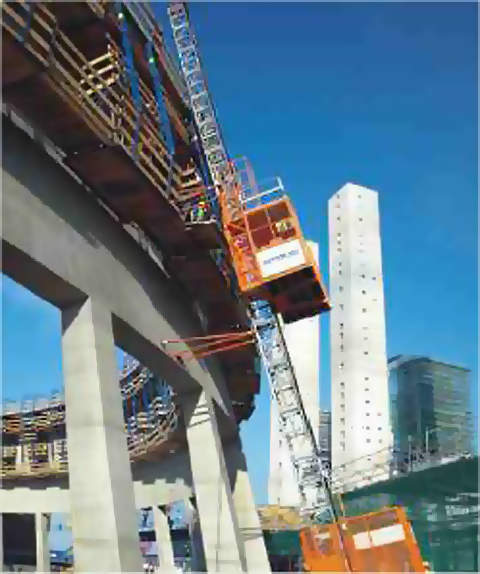

Work platforms

The work platform is applicable particularly in the building industry for mounting, maintenance work, painting and similar jobs. For movement along the construction site the work platforms can be equipped with a steerable chassis. The 2t and 3t capacity model can also come with a driven rear axle.

The platform is moved along the mast by means of electric motors that engage their pinions with the rack mounted on the mast. It is the same rack-and-pinion system as used in hoists and elevators. The work platform can be used either free-standing or anchored to the building.

Suspended platforms

Suspended platforms are designed as a modular construction, which makes it possible to assemble any size in the range of 2m to 12m. All steel parts of the platform and suspension beams are hot dip galvanised.

The supporting structure of the suspended platform is welded of quality steel profiles, and the floor is made of aluminium sheeting with an anti-skid surface. The individual platform sections are bolted together with strength bolts and self-locking nuts. The platform is equipped with wheels for transfer on the construction site.