Mee Industries is a specialist provider of innovative, cost-effective fog solutions for applications in the power generation and industrial industries, including gas turbine inlet air cooling.

Gas turbine inlet cooling systems

Mee Industries is the original developer of inlet air cooling, a technology designed to increase gas turbine power output. Since 1990, over 700 Mee Industries gas turbine inlet cooling systems have been installed in power plants, processing plants and generation stations worldwide.

Inlet air cooling systems

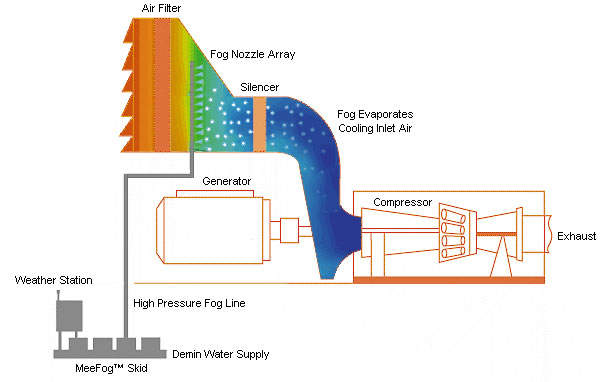

Mee Industries is the world leader in gas turbine power augmentation with inlet air fogging. A MeeFog™ inlet air cooling system will increase your gas turbine power output at a fraction of the cost of new power equipment; payback can be less than one year. Because of this many large electric power utilities have adopted MeeFog systems for their entire gas turbine fleet at existing and new power generating sites.

A MeeFog system offers the following benefits:

- Increases output by at least 20%

- Improves heat rate by up to 5%

- Reduces NOx emissions by up to 30%

- Up to 100% evaporation efficiency

- Easy retrofit and fast installation

- Fog inter-cooling gives additional boost

- Reduces fuel consumption

Fog cooling systems

Fog cooling is an extremely cost-effective way to improve the output of existing plants and inlet fogging can make a big difference in the economics of a new plant. For example, the cost per kilowatt of a new plant can be reduced by as much as 15% just by adding a MeeFog system.

Mee Industries is able to deliver and install cost-effective power-boosting fog cooling systems with a typical project lead time of 12 weeks. Fog cooling systems can be installed on existing turbines with as little as 24hr of outage time.

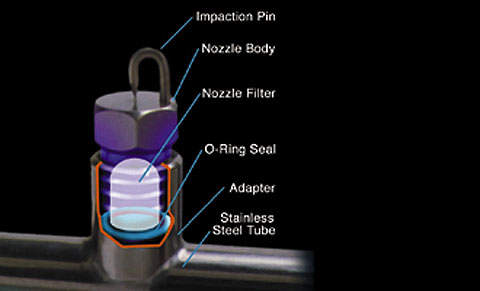

Impaction-pin nozzles

Mee Industries manufactures the world’s best impaction-pin nozzle. Droplet size is the most important factor governing fog system performance. Smaller droplets mean faster and more efficient cooling, less wetting of duct surfaces and greatly reduced compressor blade distress. The MeeFog impaction-pin nozzle sets the standard for inlet fogging nozzles and has been shown to consistently outperform other nozzles.

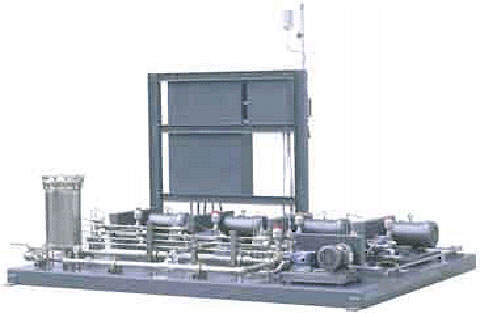

High-pressure skids

MeeFog high-pressure skids undergo rigorous quality control checks and are made with the highest quality components for reliable operation. The self-contained MeeFog skids are reliable and carefully engineered, and each skid comes with a programmable logic controller (PLC) control system.

MeeFog skids have been supplied to several major utilities and GT OEMs with a large number of repeat orders. Installations can be done with only a one to two-day outage, and explosion-proofing is available, to prevent internal or external explosions that could ignite either the transfer media or the surrounding atmosphere.

Inlet air cooling system research and development

Mee Industries’ research and development program is designed to continuously optimize and enhance the performance of the MeeFog inlet air cooling system.

Mee Industries has a fully equipped research facility that is dedicated to gas turbine inlet fogging research. This includes a 35ft, 6,000ft/min (11.5m, 1,829m/min) wind tunnel specially designed to analyze fogging flow in gas turbine intake ducts, state-of-the-art laser scattering measurement devices to monitor droplet behavior, and other analytical tools and software.