Since 1978 Field System Machining (FSM) has provided field machining solutions to steel mills, power plants, ships, factories of all types, aluminum mills, refineries, forges, chemical plants and construction sites on four continents. We provide on-site, in-situ and in-place machinery repair.

In addition to working directly for producers we also work for OEM, outage, maintenance, general contracting, turbine, and engineering firms. Furthermore, we maintain one of the world’s largest portable machine tool inventories. FSM’s results are precise, efficient and cost-effective.

Field machinery repair services for power plants

We provide a range of field machinery repair services for power plants, including the following.

Steam path repair

At FSM, keeping your steam path maintenance costs to an absolute minimum without a sacrifice in precision quality or system performance is our first and only priority. That is why we offer the industry’s most comprehensive array of expert, specialized steam path services, including:

- Complete shop and on-site NDE

- Computerized area check

- Complete welding and heat-treating capabilities for joints, integral root radial seals, partitions and blade rings, set-back faces, crush pins, and packing and seal hook fits

- Steam path repair assessments (alternative repair recommendations instead of often unnecessary and costly replacement parts)

- Manufacture and replacement of blades and buckets

- Replacement and repair of erosion shields

- Replacement and repair of tie wires

- Weld repairs to lashing lugs

- Complete welding capabilities and refurbishment to tenons

- Shroud band/cover replacements

- Stationary component refurbishment of nozzles, diaphragms and blade rings

- Manufacture, machining and replacement of seals and packing

- Main stop valve crack repairs, and all other steam path crack repairs

- Valve seat replacements; valve seat machining; steam chest repairs

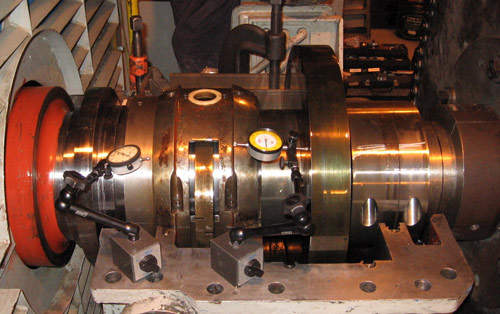

Journal / shaft machining for power plants

Our journal / shaft machining for power plants includes tooling, grinding and polishing of journals, collector rings, thrust faces, hydrogen seals (applicable to turbines, generators, motors, pumps, drive shafts and propulsion shafts); welding and reconditioning of damaged or worn shafts; reverse engineering of old shafts; and manufacturing of new replacement shafts and components.

Line-bore machining for power plants

We provide line-bore machining of all types for power plants. Equipment we can line-bore machine includes:

- Turbine casings and inner cylinders, nozzle blocks, bearing seats, and valves of all types and sizes

- Manways, valve bodies and seats

- Upper, intermediate and lower seal and wear rings/surfaces

- Gate-valve sealing faces, wicket-gate bores, and discharge and throat rings

- Pump and compressor housings and cylinders

- Gearboxes

- Equipment stands/frames

- Stern tubes and rudder and driveshaft bushings

- Inspection bore ring samples, bottle boring, over boring and bore plug manufacturing equipment

Our over-boring capabilities range from 2in upwards, and bore capabilities are from 2¾in upwards. Standard bottle-bore capabilities are up to 14in, but we can provide larger on request.

Field machining for power-plant mills and components

We offer a wide range of field machining services for power plant mills and components, including gearboxes, crane pin bores, cylinder bores, and coupling bolt holes of all kinds.

Milling services for power plants

FSM provides a variety of milling services for power plants, including:

- T-slot and keyway cutting

- Horizontal-joint milling for turbines, pumps, valves and compressors

- Machining of support ledges for generator spider assembly (hydropower units)

- Machining foundations for engines, pumps, generators, compressors and motors

Honing, drilling and welding for power plants

Our honing, drilling and welding services for power plants include drilling/honing in all positions; tapping and internal/external threading; counter-boring and spot facing; and honing capabilities from 2¾in up to 12in, for items up to 40ft long.

Flange-face machining for power plants

We provide flange-face machining for power plants, including for the following equipment: turbine casings, splitline repairs, pressure vessels, heat exchangers and process reactors; coupling flanges (elliptical, oval and circular configuration can be accommodated); and hand holes, manway flanges, access doors and valves of all types and sizes.

Combustion turbine repair services

FSM provides high-quality, detailed and comprehensive field and shop repairs for combustion turbines and turbine components, including:

- Fuel nozzles and combustion liners

- Hot gas path component repair services

- Stationery IGT component repairs

- Airfoils and vane segments

- Blade and bucket repair services