Farrat Isolevel manufactures and supplies a comprehensive range of products and systems for power-generation equipment focused on three areas: structure-borne vibration, acoustic, noise and shock isolation; thermal break connections; and machine anti-vibration and precision-levelling mounts.

Farrat has supplied a global client base for over 50 years with solutions that are used throughout the power-generation, building construction and industrial sectors.

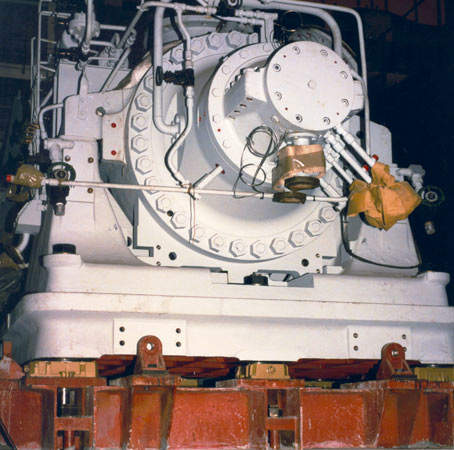

Precision-levelling units for power-generation equipment

Levalators and precision wedge-levelling elements are used to ensure the optimum performance of high-precision equipment and machinery by enabling accurate alignment and high stiffness anchoring to concrete or steel foundations.

Primary or intermediate supports or pre-levellers

Levalators can be used as primary or intermediate supports or pre-levellers where they are used to set up levelling blocks which can then be grouted in. They provide:

- Accurate precision alignment

- Rigid support for maximum machine-bed stiffness

- Total machine-to-foundation integration

- Systemised, predictable and economic precision-machine installation

- The facility to re-align machines with minimum production loss

- High bolt tensions without bed distortion

Steam turbines, turbo machinery / gas turbines, generators, compressors, boiler feed pump sets, long bed machine tools (roll grinders, lathes and plano-millers), and rolling mills and large process machinery have been installed on Farrat levalators.

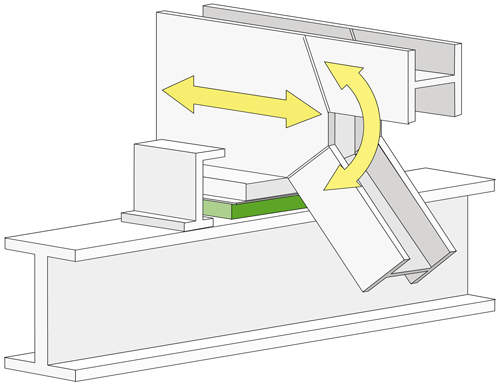

Slide bearings for power-generation equipment

Farrat slide bearings for power-generation equipment are high-quality sliding point bearings for precise, low-friction transmission of loads to the supporting structure. They allow building structure elements to slide and / or tilt relative to each other, and can incorporate structural damping or, in some variants, low-frequency vibration isolation.

Our slide bearings for power-generation equipment can be used for steel, in-situ concrete, pre-cast concrete and pipeline constructions.

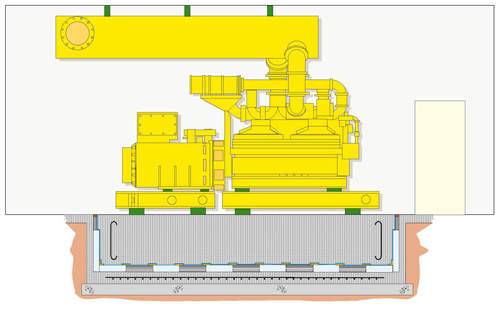

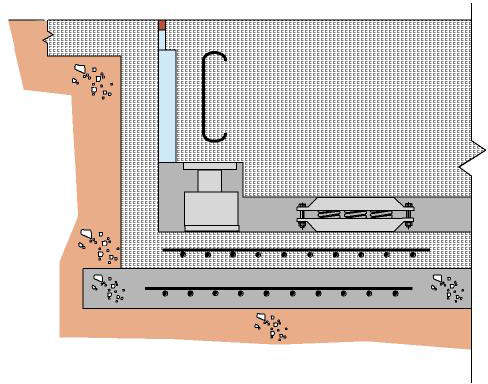

Isolated foundations for power-generation equipment

Farrat isolated foundation systems are used globally in a range of industrial and power-generation installations to provide effective, low-frequency isolation of machinery and equipment.

Our isolated foundations provide:

- Active isolation to prevent noisy, vibration-emitting equipment from disturbing its surroundings

- Passive isolation to prevent sensitive equipment from being disturbed by structure-borne vibration from surrounding disturbances and earthquakes

- Increased machine-frame stiffness to maintain alignment during changes in applied static and dynamic loads

- Increased inertia mass of the machine and reduced vibration through mass damping

- Lower centre of gravity to improve stability

- Distribution of static and dynamic loads over a greater ground area

- Increased lifetime, maintenance intervals and availability of equipment

Turbo machinery / gas turbines, gas and diesel gensets, generators, compressors, pump sets, ID, FD and PA fans, long bed machine tools (roll grinders, turbine rotor lathes and plano-millers), rolling mills and large process machinery (coal crushers and coal mills), and equipment and buildings installed on offshore platforms have all used Farrat’s isolated foundations.

Vertical and horizontal-performance isolated foundations

ISOMAT foundation isolators used in conjunction with FVF Farrat base void filler. LVI and/or ISF sidewall vibration isolation materials provide highly predictable vertical and horizontal performance characteristics with natural frequencies down to 6Hz.

Lateral foundation isolations

Where vertical vibration isolation is not required but there is a risk of disturbance to nearby equipment, such as from earthquakes, Farrat offers LVI and ISF lateral foundation isolations that are specifically designed for sidewall vibration isolation of foundations. These can also be used when there is a requirement for very high foundation stiffness.

Coil-spring and viscous-damper isolated foundations

FSL steel coil-spring isolated foundations can be used either on their own or in a variety of combinations and support arrangements, including with FV viscous-damper isolated foundations. They provide natural system frequencies down to 3.2Hz.

Vibration-analysis surveys, technical and design advice

Farrat can offer vibration analysis surveys, technical and design advice and will design the appropriate isolation systems to meet a customer’s specific technical requirements. We then provide full construction-layout drawings and installation instructions drawings and if requested can offer installation supervision or a full on-site installation service.