TTT is an engineering company and EPC focused on gas turbine air filtration and acoustic equipment. We are independent from filter manufacturers, enabling us to provide unbiased and independent consultancy and solutions.

In addition to the company’s consultancy services, TTT also performs retrofits and upgrades on existing sites.

Gas turbine air intake filtration (AIF) consultancy

TTT provides independent and unbiased engineering consultancy focused on gas turbine air intake filtration.

We recognise that there isn’t a single filter manufacturer that holds the best and most competitive product in all applications and product ranges such as water removal, prefiltration, fine filtration and Hepa filtration. We therefore believe that it is key for gas turbine end-users to source advice from independent, experienced and knowledgeable AIF system engineers, to define the correct specifications at the outset of any new or retrofit project. TTT provides such a service in the market.

Early in 2009, TTT was appointed as consultant to the number-one oil and gas turbine-user in Europe, to provide advice and to co-write the air intake filtration specifications for all new gas turbine projects. This experience and reference serves to indicate our knowledge and position in the market.

Weather protection for Hepa filters

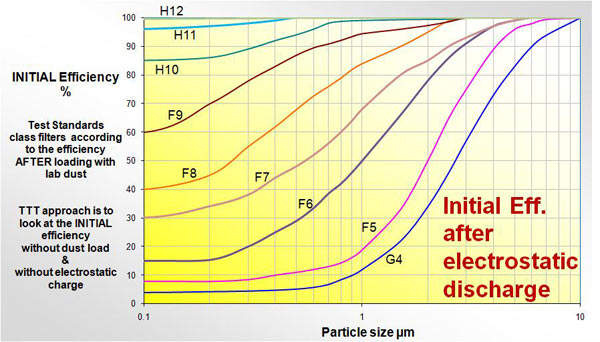

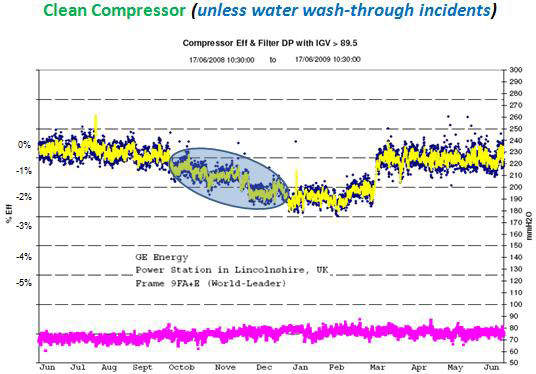

TTT strongly believes in Hepa filtration as a means to enhance gas turbine availability, reliability, efficiency and therefore profitability. But we also believe that weather protection is vital to protect Hepa filters for their correct operation. Too often we see a mediocre prefiltration that results in fine or Hepa filters being corrupted, resulting in compressor fouling.

Air intake filtration (AIF) upgrades and filter elements

We are often invited to upgrade GT AIF systems to Hepa efficiency and we give major importance to upstream water removal. The effectiveness of the water removal is dictated by the interaction of the weather hoods, marine louvers, coalescers, prefilters and the configuration in which they are put together. The correct implementation of water removal results in a low Dp across the whole filter house, as well as the absence of phenomena such as water washing through the filters that result in compressor fouling (even with Hepa filtration).

Air cleaning to Hepa standards

Our approach as quality AIF system engineers is to implement technologies that work in harmony together and provide a high-performance (i.e. low-Dp) air cleaning solution to Hepa standards.

We take great pride in our work and, after years of experience, we continue to be fascinated by the GT technology that our AIF systems protect. As the latest trends in the market demonstrate, the interaction between AIF and GT performance justifies important studies and upgrades.

Please do not hesitate to contact us for advice, and independent implementation of such, about the potential upgrade of GT AIF systems. We focus on F-class gas turbines, as well as smaller gas turbines offshore.