Stern Laboratories Inc carries out reliability and safety studies for nuclear power operators, nuclear reactor designers, fuel vendors, government agencies, and nuclear equipment suppliers.

The company develops specialised devices such as fuel inspection and handling tools and electrically heated nuclear-fuel simulators for CANDU and PWR heat transport systems. Simulations are also provided for safety system, reactor fuel, and fuel channel parts such as inlet strainers.

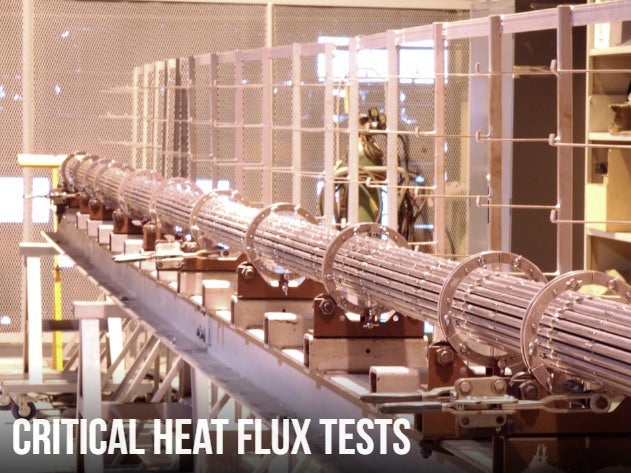

Critical heat flux experiments for nuclear power facilities

Stern Laboratories’ innovative hardware and software accurately control experimental thermal hydraulic conditions, and carry out high-speed data acquisition and reduction.

Critical heat flux (CHF) experiments are performed in full-scale, horizontal CANDU fuel channels at reactor operating conditions. This is achieved using directly heated fuel simulations demonstrating 28, 37, and 43 element CANDU geometries.

Fuel simulations feature moveable internal thermocouples, remotely positioned to measure temperature of critical power (dryout) in downstream bundle element surfaces.

Boiling transition (BT) tests are carried out in full-scale, vertical boiling water reactor (BWR) fuel channels using indirectly heated fuel simulators. These are equipped with internal thermocouples (up to 12 per rod) to determine critical power at precise locations.

Using these heated fuel simulators, Stern also performs departure nucleate boiling (DNB) tests in vertical, pressurised water reactor (PWR) channels.

A total of 16MW of 12-pulse-rectified DC power is available during testing, using 13 controlled power supplies. Either 330V or 660V can be provided.

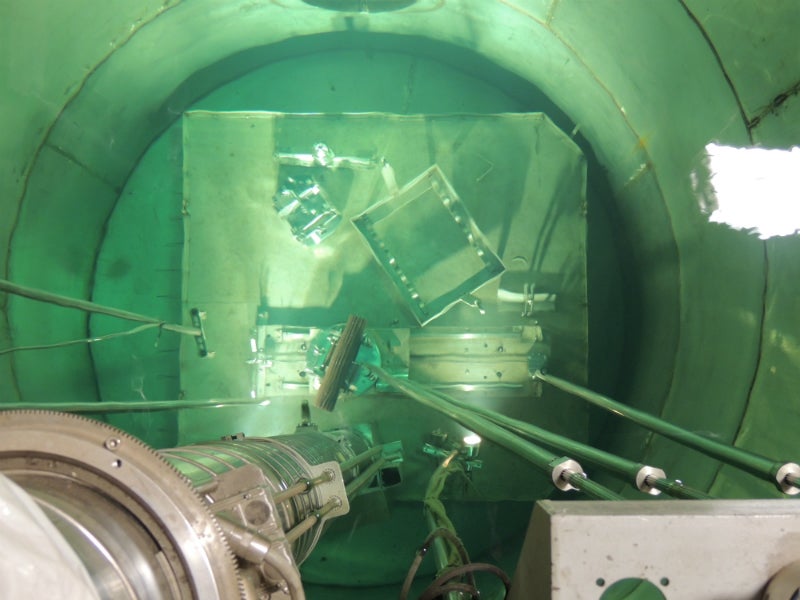

Remote fuel handling and inspection tools for nuclear pools

A range of remote inspection and handling tools have been developed and tested for spent nuclear fuel stored in facility pools.

Stern Laboratories’ Fuel Inspection Tools are suitable for clasping, prying, and surface cleaning operations carried out at the bottom of fuel inspection pools. They can be used with a universal tool handle, which is manually controlled from above the pool. Tools contain passivated stainless-steel to minimise corrosion.

Our “Light Pipe” camera systems offer high-resolution video capabilities and are a cost-effective alternative to periscopes for underwater inspections.

Stern maintains a large water tank at its Hamilton Laboratory to simulate the nuclear reactor’s spent fuel pool during inspection tool prototype testing and inspector training.

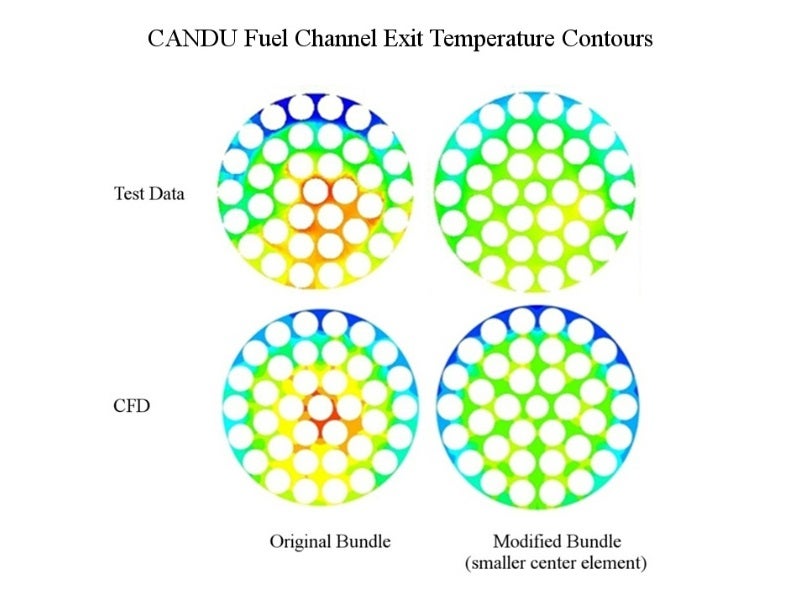

Computational fluid dynamic simulation software

Stern Laboratories employs computer simulation technology to develop methodologies for reactor design and safety margin improvement.

The simulation projects include:

- Best practice computational fluid dynamics (CFD) technology with advanced turbulence models

- High-performance computing (HPC) with parallel processing capability

- Single and multiphase CFD modelling of the reactor flow channels beneficial for rector thermal-hydraulic simulation studies

- Various CFD results such as reactor flow channel cross-sectional temperature distributions, single and two-phase flow channel pressure drops, and void fractions

- CFD model validation with experimental data and benchmarking against other codes

Flux detector removal tools for CANDU reactors

Stern Laboratories manufactures and supplies remotely operated devices for the removal of highly radioactive ICFDs in CANDU nuclear power facilities.

ICFDs are installed in CANDU reactor cores to monitor the neutron flux level during normal operating conditions. They are made from Inconel wire and are 1mm-3mm in diameter, measuring 20m in length and coated with vanadium or platinum.

Chopper tools cut ICFD detector wires into short lengths and place them in shielded temporary storage containers using a vacuum system. Up to 12 containers can be stored in a lead-shielded flask that is easily transferred to permanent storage.

ICFD removal usually takes place after they have reached the end of their ten to 20 year lifespan.

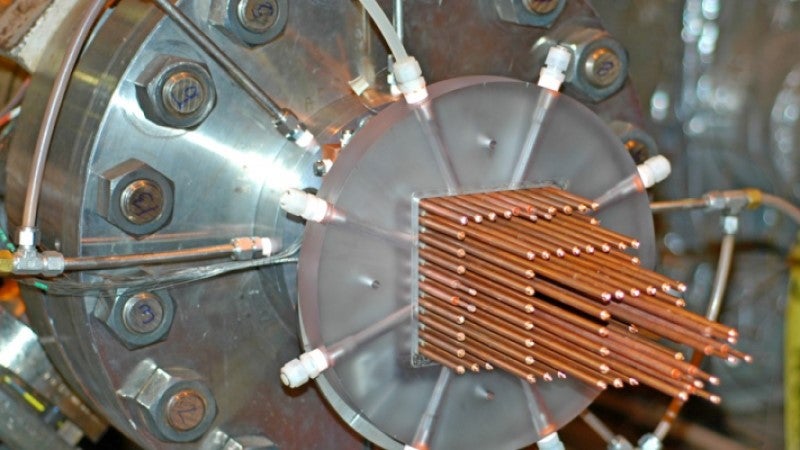

Directly and indirectly heated fuel simulators / heater rods

Stern Laboratories has extensive experience in designing, fabricating and testing high power and high heat flux fuel simulators / heater rods for various heat transfer applications.

Fuel simulator / heater rod designs have been extensively tested to support the BWR, PWR and CANDU nuclear industries, as well as various other heat transfer experiments.

The fuel simulators / heater rods have design voltages up to 600V with maximum surface heat fluxes exceeding 400W/cm2 and linear powers over 125kW/m. Maximum surface temperatures have exceeded 1,100˚C. In addition, an assortment of custom heating profiles (cosine for example) and instrumentation are also available.

Fuel simulators / heater rods are custom-built to suit the customer’s specific application. Designs may be manufactured as solid or hollow assemblies with power terminations on either or both ends of the assembly depending on the customer’s requirements. Associated hardware such as custom seal coolers and power clamps are also available for design and manufacture.

About Stern Laboratories

Stern Laboratories is a highly skilled, professional engineering company that has served the nuclear industry in Canada and internationally since 1962.

The laboratory uses state-of-the-art data acquisition systems and has a 16MW DC power supply with 13 individually controlled areas. It has one of the highest power capacities in the market and is an extremely versatile heat transfer facility.

Laboratory facilities are kept up-to-date to accommodate new experiments and meet specific customer requirements.