COMEM Group is manufacturing and supplying a wide range of different types of components and bushings for power and distribution transformers. We provide world-class consulting services, product solutions, and after-sales support during the entire transformer lifecycle for transformer manufacturers, service organizations and end-users. We can support our customers with an on-site transformer service from general maintenance and testing up to digitalization of your transformer.

COMEM offers a comprehensive range of products designed for transformer manufacturers (OEMs), service organizations, and end users, aimed at enhancing performance and durability throughout the lifecycle of transformers. Our components and bushings facilitate efficient operations and allow end-users to monitor asset health and plan for proper maintenance.

Our extensive product portfolio includes 12 distinct product lines, including bushings, advanced measurement and safety devices, and innovative solutions for smart grids, with both analog and digital outputs.

We provide tailored solutions for various applications and installations in diverse environments, from Offshore & Marine to seismic areas. An experienced team supports customers during the entire project lifecycle, from product selection to installation, commissioning, and after-sales support.

Product offerings:

Bushings cater to a wide variety of requirements based on transformer design, current capacity, and rated voltage. The range includes:

- Porcelain oil bushings for low-voltage and medium-voltage applications

-

- Nominal voltage: 1 – 52 kV

- Rated current: 250 – 8000 A

- Compatible with EN and DIN standards

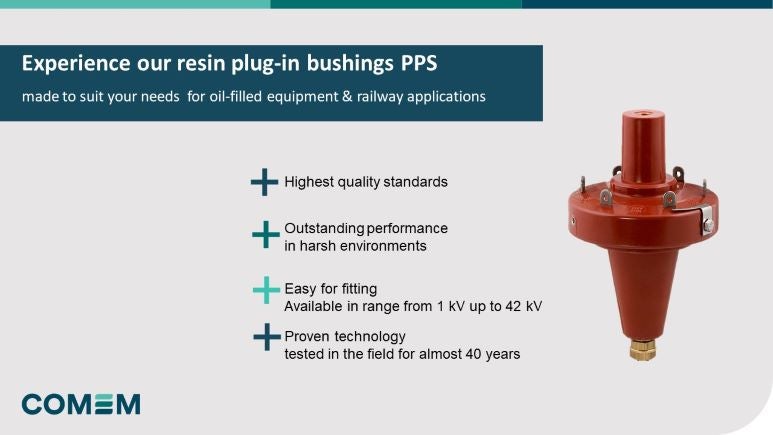

- Epoxy resin bushings for low-voltage and medium-voltage applications

-

- Nominal voltage: 1 – 42 kV

- Rated current: 250 – 8000 A

- Compatible with IEC standard

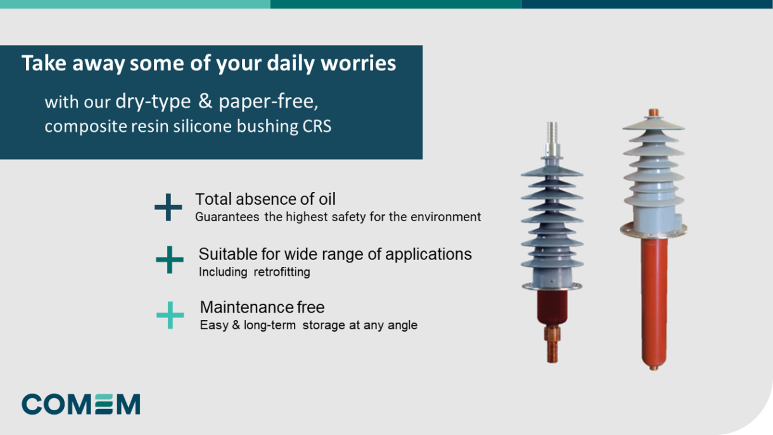

- Resin silicon bushings

-

- IEC range: Um ≤ 72.5 kV, Ir ≤ 6300A

- IEEE range: Um ≤ 34.5 kV, Ir ≤ 3000A

- Qualified as per IEC60137 and IEEE C57.19.01- 2000

- Compatible with EN and DIN standards

Conventional accessories

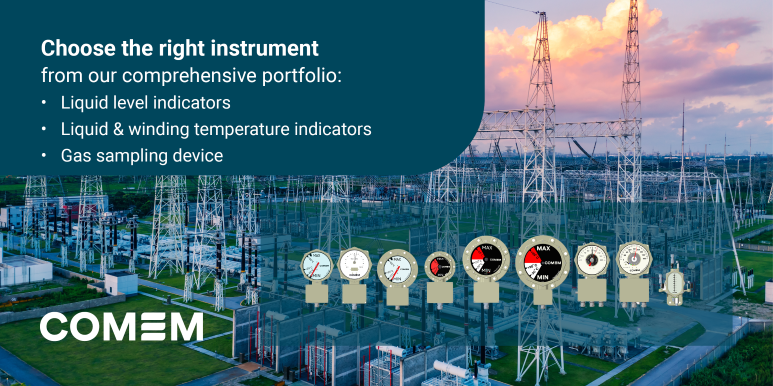

Essential for safe and efficient transformer operations, our conventional accessories are suitable for both new installations and retrofits. Options include:

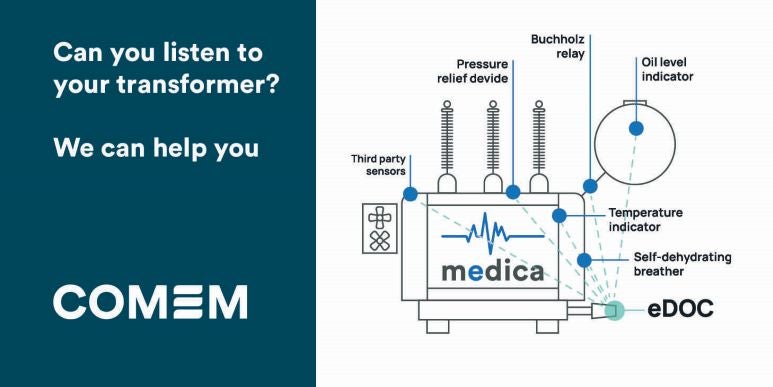

- Dehydrating breathers that prevent humidity from entering transformers to avoid aging and outages.

- Buchholz relays that detect gas accumulation and monitor oil flow.

- Integrated safety devices that control pressure, temperature, oil level, and gas in hermetically sealed transformers.

- Liquid level indicators to monitor oil levels to prevent failures due to leakage.

- Pressure relief devices protecting against overpressure and explosions.

- Shutter valves that prevent oil drainage during accidental leaks.

- Temperature indicators for monitoring temperature variations in liquid-filled transformers.

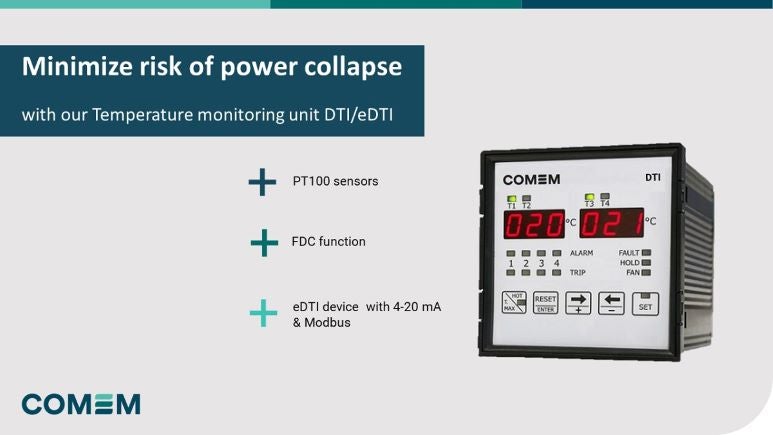

- Temperature monitoring units for dry-type transformers.

Digitalization and devices for smart transformers

Transitioning from traditional grid systems to efficient smart grids is crucial.

Our eDevices for smart transformers enable continuous monitoring and data gathering, allowing for remote or on-site data collection essential for predictive maintenance. These devices can be installed on new transformers or retrofitted to existing assets. Options include:

- Buchholz relays for smart transformers for continuous monitoring of gas accumulation and oil flow, maintaining redundancy with conventional systems.

- Data aggregators that process data from multiple sources for a unified asset health overview.

- Integrated safety devices for smart transformers that monitor pressure, temperature, oil level and gas as in the conventional device. They also continuously monitor from remote locations temperature and pressure and control pressure variations in the fins.

- Liquid level indicators for smart transformers that monitor any unexpected or accidental oil leakage.

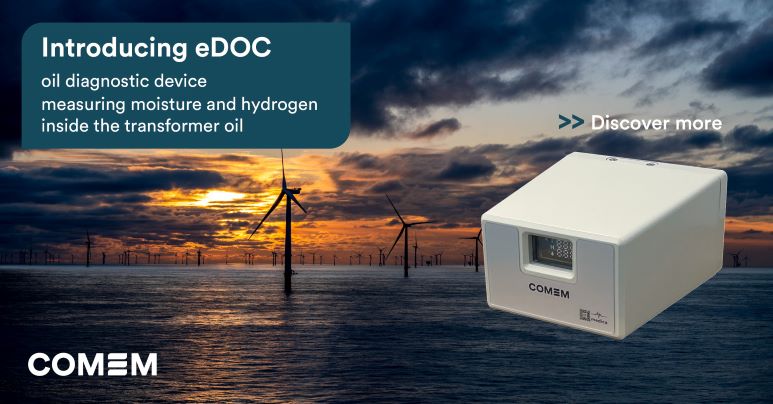

- Oil diagnostic devices (DGA) for smart transformers that monitor the presence of dissolved gases and moisture in transformer oil.

- Pressure relief devices for smart transformers that protect your transformer explosion by continuously monitoring and controlling pressure remotely.

- Self-dehydrating breathers for smart transformers that constantly secure transformers from moisture intake and collect data online.

- Temperature indicators for smart transformers that monitor the temperature variations in the transformer oil and winding at any time and remotely

- Temperature monitoring units for smart transformers that control at any time and from remote any temperature variations in dry-type transformers.

Fiber optic temperature measurement systems (FOTEMP)

Utilizing fiber optics for temperature monitoring allows continuous and accurate proactive measures to prevent supply compromise.

The system consists of:

- Fiber optic devices

- Fiber optic sensors

- Fiber optic accessories

- Service & Calibration

All our eDevices and Fiber optic systems can also be connected to third-party devices and are part of our modular monitoring ecosystem for transformer diagnostics MeDICA.

MeDICA, an open Monitoring Ecosystem for transformer diagnostics, provides a complete solution that includes products and services that can enable a longer and more efficient transformer life cycle.

By identifying and preventing premature transformer failures through monitoring, you can ensure business continuity and significantly reduce operational costs. We can help you develop a sustainable and data-driven predictive maintenance strategy.

COMEM service offers a full range of on-site services from general maintenance and testing up to digitalization of the transformer

- After-sales support for transformer accessories & bushings

- Technical inquiries

- Installation & Commissioning

- On-site service

- Spare parts

- Original spare parts are deliverable within 72 hours, solving any urgent request

- Transformer service

- General maintenance & Electrical testing

- Transformer digitalization

- Installation & Commissioning

- Accessories replacement & retrofitting

- Oil analysis*

* In collaboration with an external accredited laboratory

- Training & Consulting

- Tailor-made training

- Pre-sales support

- Specifications analysis

- Product identification

- Tests

About us:

COMEM was established in 1962 and is headquartered in Montebello Vicentino, Italy.

The company’s commitment is to provide advanced and reliable solutions that meet industry standards and support the effective management of transformer health, contributing to safer and more efficient energy systems.

Local support is guaranteed worldwide through an extensive network of agents and distributors called Authorized Partners.

Our manufacturing units are in Italy, China, Germany, Singapore, and Brazil.

We have numerous references in various applications and environments and a solid and proven installed base of components and bushings for power and distribution transformers.