For over 70 years, IKEUCHI has been at the forefront of research and development in spray nozzle technology, addressing complex challenges across various industries.

One of our key innovations is the Gas Turbine Inlet Air Cooling System. This crucial technology helps ensure a stable power supply during the summer, a season of high electricity demand.

Why Gas Turbine Inlet Air Cooling?

A gas turbine generates power by drawing in ambient air. However, in the elevated temperatures of summer, the air expands, reducing its density and resulting in less air mass entering the turbine. This reduction in inlet air results in a drop in power output.

It is widely observed that power output falls by approximately 0.6 to 0.8% for every one-degree Celsius rise in ambient air temperature. The technology, which cools the inlet air, increases its density, and allows more air to enter the turbine, preventing a drop in power output, is known as “Gas Turbine Inlet Air Cooling (GTIAC).”

Methods of Gas Turbine Inlet Air Cooling

There are three primary methods for cooling inlet air: evaporative cooling, chiller systems, and inlet fogging.

Evaporative cooling uses the process of water evaporation to cool the air, making its system relatively simple and cost-effective. However, its efficiency is limited in high-humidity environments.

Chiller systems use refrigerants to cool the air, providing greater cooling potential, but they require a higher initial investment and cannot be retrofitted to existing gas turbines.

IKEUCHI, a specialist in spray nozzle technologies, offers a Gas Turbine Inlet Air Cooling System that uses inlet fogging, a method of cooling by water spraying, renowned for its superior cost-effectiveness.

This system sprays a fine fog called “Semi-Dry Fog®” with a mean droplet diameter of 10 to 30 μm. By utilizing its heat of evaporation to cool the inlet air, the system increases the mass of air and enhances turbine efficiency.

Three Types of Inlet Fogging (Water Spraying)

While there are three types of inlet fogging approaches available, IKEUCHI can accommodate any of these, designing and providing an optimal system tailored to customer requirements, facility specifications, and onsite environments.

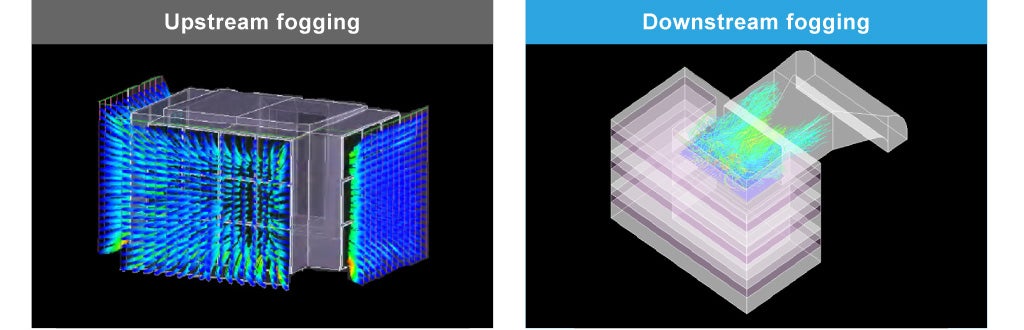

- Upstream fogging: fogging outside the inlet air filter for pre-filter cooling

- Downstream fogging: fogging inside the inlet air duct for post-filter cooling

- Wet compression: injecting fog directly into the compressor

Configuration of Gas Turbine Inlet Air Cooling System

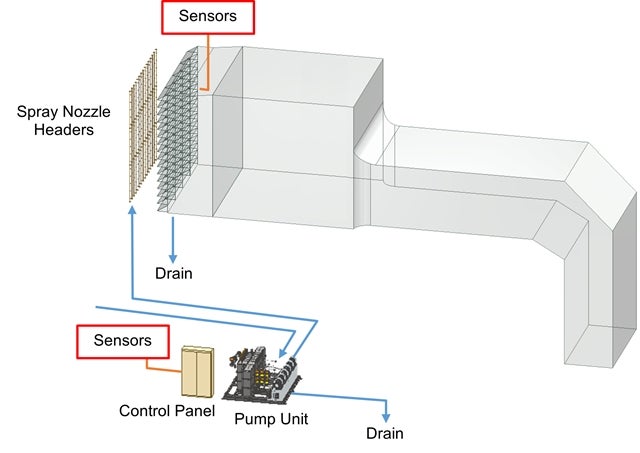

IKEUCHI’s gas turbine inlet air cooling system consists of four key components:

Spray Nozzle Headers: Evenly spray “Semi-Dry Fog®” to efficiently cool the inlet air using the heat of evaporation, increasing air density and mass.

High-pressure Pump Unit: Supplies high-pressure water to the spray nozzles on the headers.

Temperature and Humidity Sensors: Continuously monitor inlet air temperature and humidity in real time, sending data to the control panel.

Control Panel: Optimally adjusts the spray volume in response to variations in inlet air temperature and humidity, enabling automated system operation.

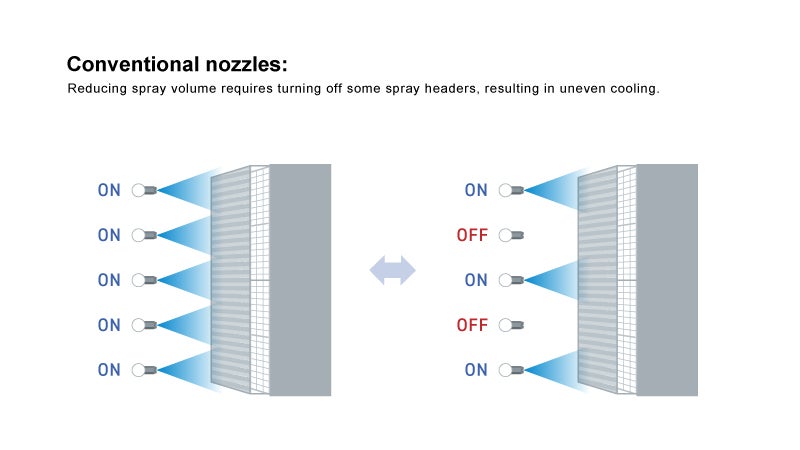

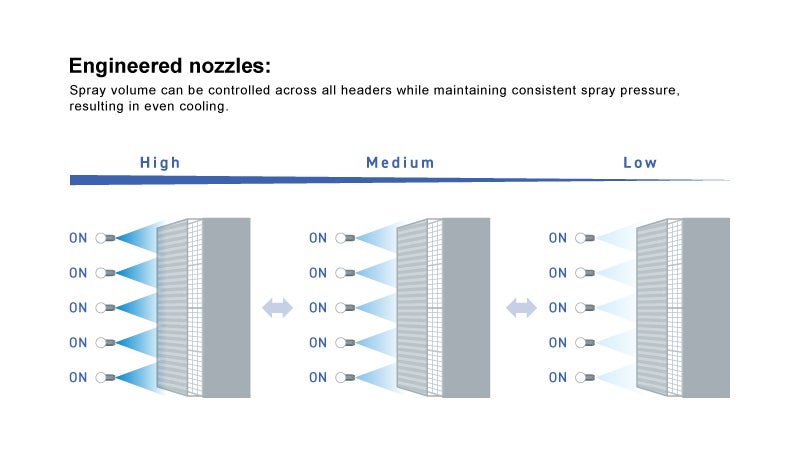

Conventional Nozzles for Inlet Air Cooling

Challenges with Conventional Nozzles:

- Lowering the spray pressure was the only way to reduce the spray volume when full cooling was not needed.

- However, this led to coarse, unevaporated spray droplets.

- As a result, spray volume could only be controlled by turning each entire spray header on or off.

- This caused some sections of the target surface to be cooled by the fog, while other sections remained unsprayed, resulting in uneven cooling.

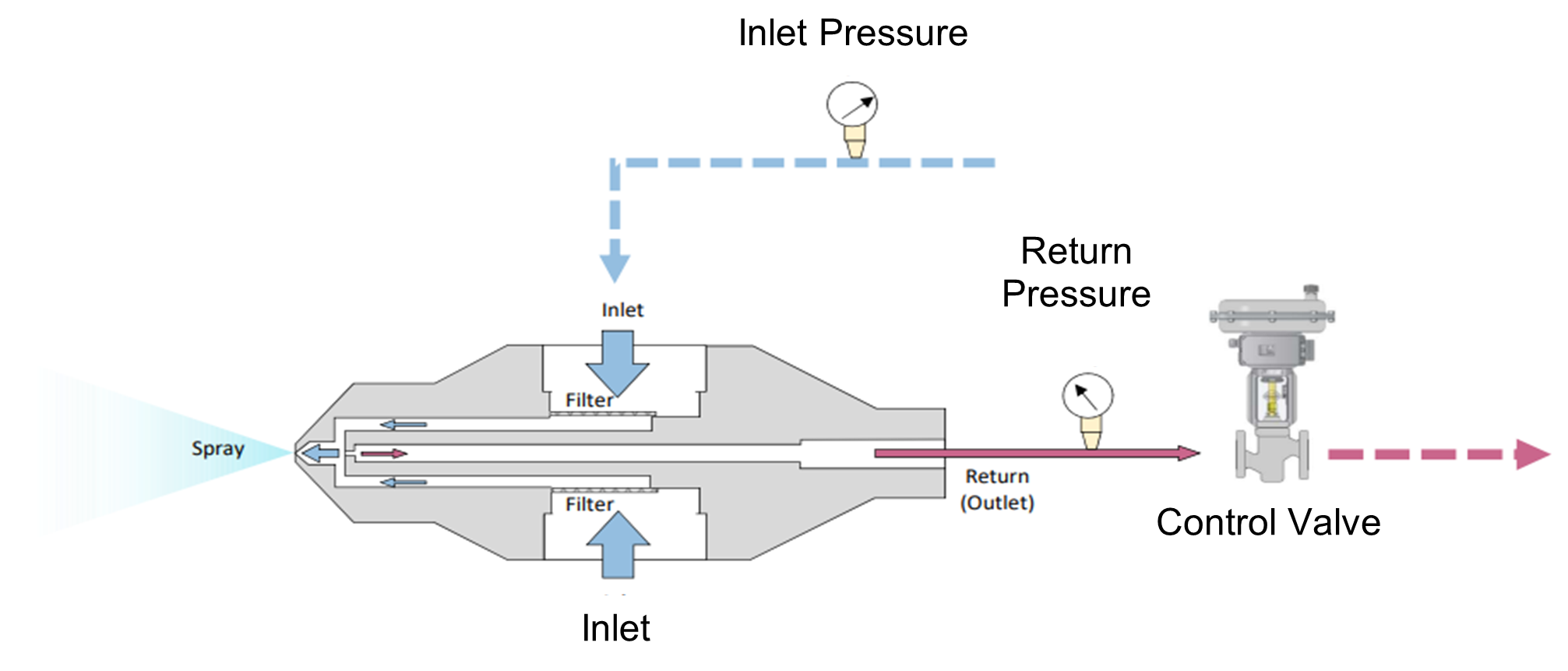

Fogging Nozzles Engineered for Inlet Air Cooling

To overcome these challenges, IKEUCHI has developed proprietary nozzles specifically engineered for inlet air cooling. The key features and benefits include:

- The spray volume across all headers can be adjusted within a 1:10 range while maintaining consistent spray pressure, ensuring even cooling across the entire surface.

- Because there is no need to lower the spray pressure, droplet size remains consistent without becoming coarser, resulting in efficient cooling.

- The system operates automatically through PID control, adjusting the spray volume to optimal levels based on variations in ambient air conditions, enabling water conservation.

Why Choose IKEUCHI?

- IKEUCHI can accommodate any of these fogging systems—upstream, downstream, or wet compression—offering tailored solutions to meet your specific needs.

- IKEUCHI utilizes Computational Fluid Dynamics (CFD) to create 3D models for simulating and optimizing system performance.

- Our inlet fogging systems are cost-effective and require minimal maintenance.

- Our upstream fogging system can be retrofitted to existing gas turbines, even while they are in operation.

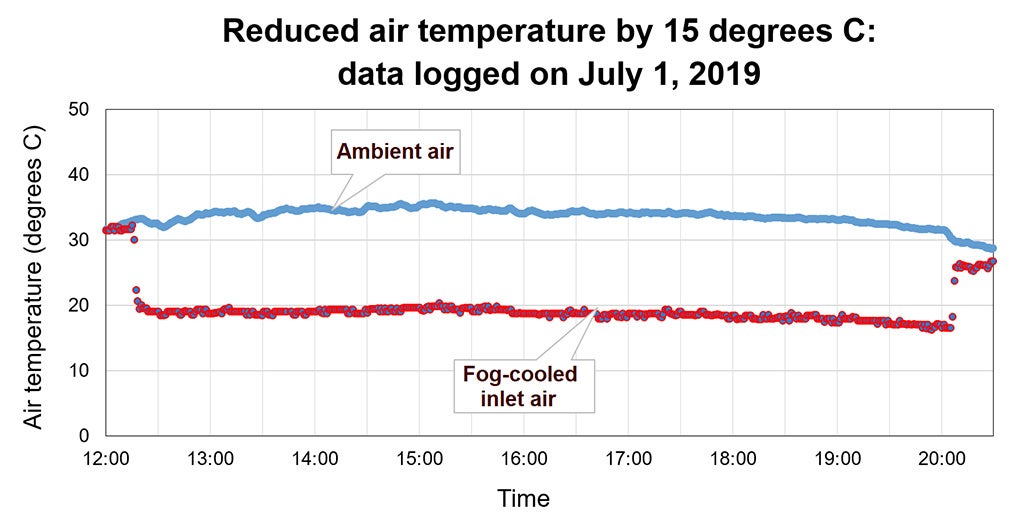

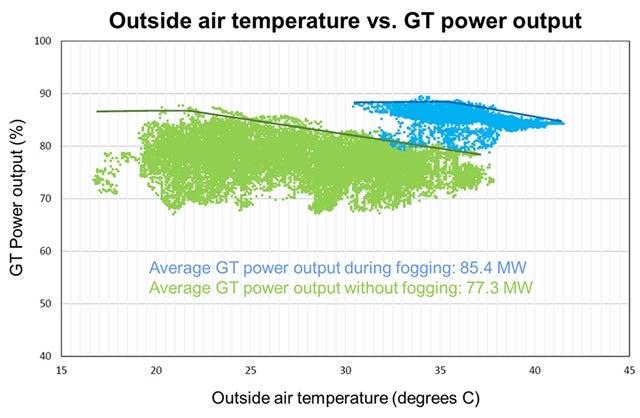

Proven Cooling Effectiveness

Our system achieved a 15-degree Celsius reduction in inlet air temperature in the Middle East.

As a result, turbine output increased by approximately 10%, from 77.3 MW to 85.4 MW.

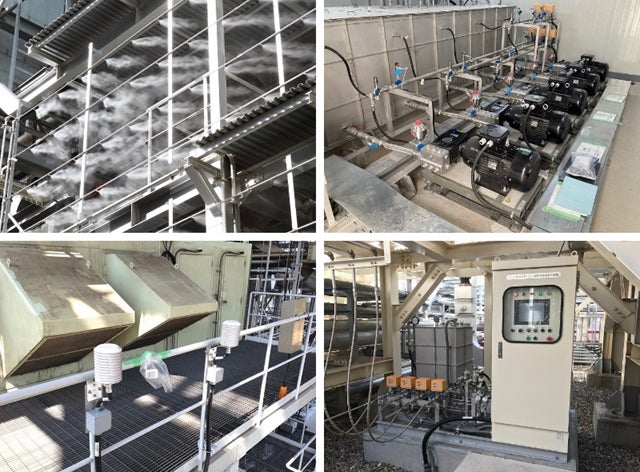

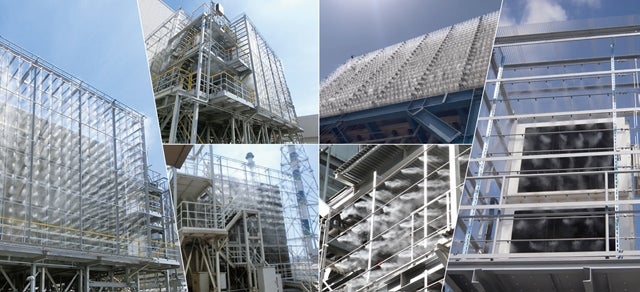

Actual Installation Examples

IKEUCHI’s gas turbine inlet air cooling systems have been successfully implemented in various regions, demonstrating their success.

Contact us today, and we are here to ensure your power supply remains stable, year-round.