GE Vernova and Japanese engineering giant IHI have signed a joint agreement to advance the development of a new gas turbine combustor that uses ammonia as fuel.

The initiative aligns with the global shift towards reducing carbon emissions in the power sector.

Ammonia, derived from hydrogen, offers a carbon-free combustion process when used in gas turbines. This positions it as a promising alternative fuel for power generation.

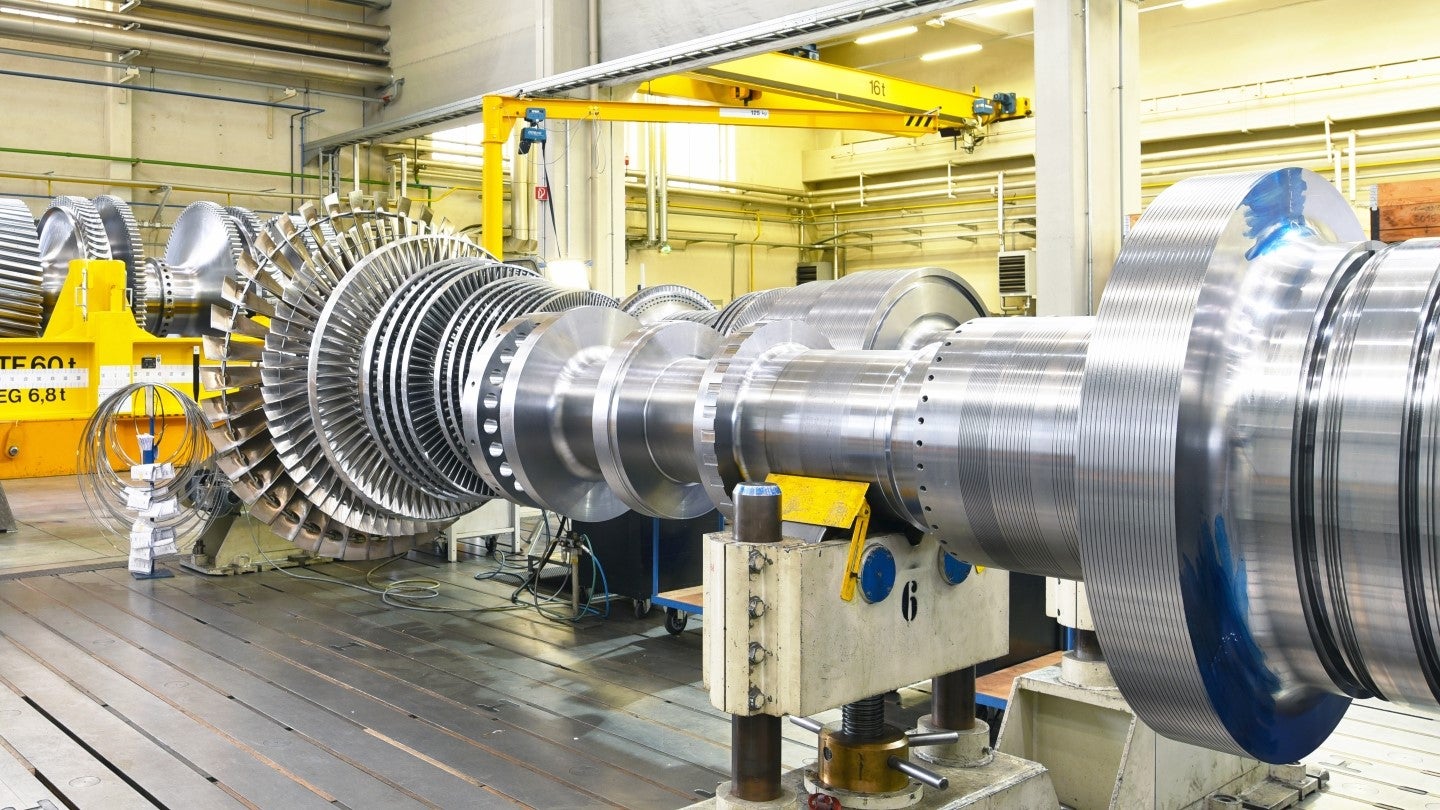

GE Vernova and IHI will develop the next phase of technology and engineering for the gas turbine combustion system, which is expected to be compatible with GE Vernova’s 6F.03, 7F and 9F gas turbines.

The partnership follows their previous memoranda of understanding and leverages IHI’s success in developing a 2MW gas turbine powered entirely by liquid ammonia.

The project achieved a reduction of more than 99% in greenhouse gases including nitrous oxide (N₂O) through ammonia combustion.

The companies aim to develop a two-stage combustor capable of burning up to 100% ammonia while meeting emission standards.

IHI’s facilities in Japan will host the combustion testing, which is crucial for refining the new combustor design.

The innovation is not limited to new power plants but also offers a path for decarbonising existing gas turbine facilities.

Power plants can switch from conventional fuels to ammonia with minimal upgrades, avoiding the need to replace current turbines.

GE Vernova hydrogen value chain director Jeffrey Goldmeer stated: “Following two years of joint studies on the economics of the ammonia value chain, we are now thrilled to open a new chapter in our collaboration with IHI and proceed to the next phase of technology and engineering as agreed in our ammonia road map to develop decarbonisation pathways that can future-proof existing investments in power generation.

“With GE Vernova’s expertise in engineering and manufacturing of gas turbine combustion systems and balance of plant systems, and IHI’s know-how in ammonia combustion technology, we will be focused on the technological development and technical deliverables, aiming for the validation of the combustion technology in the next two years, and to a potential commercially available product by 2030.”