DEWETRON manufactures powerful, easy-to-use data acquisition systems for vehicle testing, including e-mobility and battery performance, hybrid electric engines, dynamics and durability.

Measurement solutions and customised signal conditioners

The company’s systems have the highest accuracy and high bandwidth (6MHz), as well as a high sampling rate (up to 10MS), high voltage measurement range (1,600V) and fully isolated (4kV) inputs. These elements guarantee reliable and broadband measurements, including:

- Motor and inverter testing

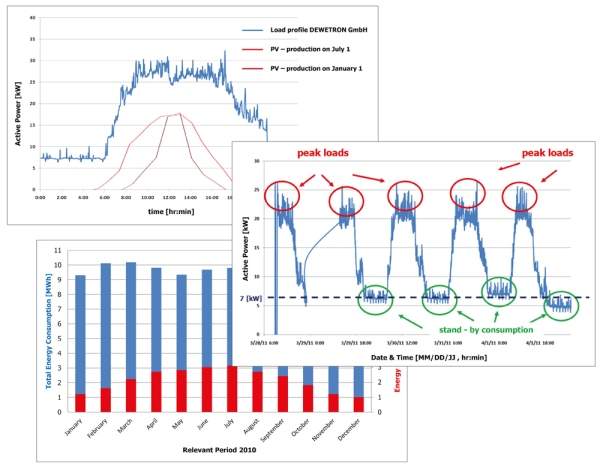

- Wind and photovoltaic testing

- E-drive testing, and more

DEWETRON’s test and measurement systems include the unique SYNC-CLOCK™ technology, which inserts data from many sources into one sync recording. This makes data analysis and processing faster and easier.

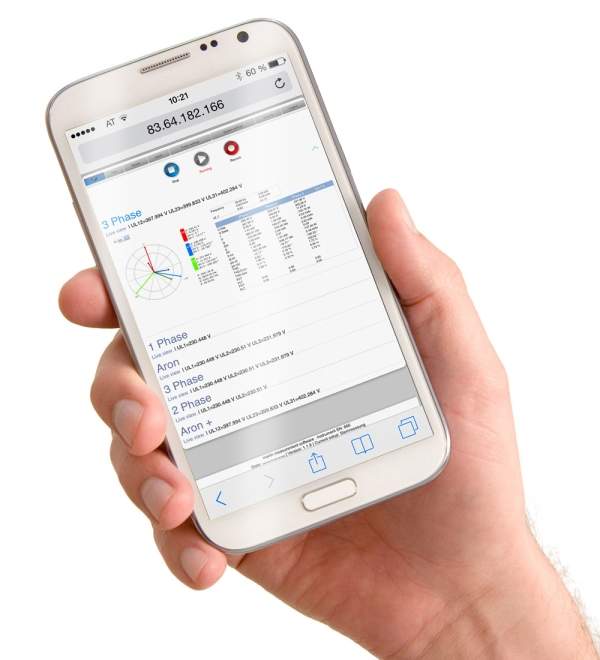

Signal conditioners are available for almost every signal and sensor, and users can design their own displays and outputs with easy-to-use software.

Frequency converters with high bandwidth

Modern frequency converters for electric vehicles work with a pulse frequency of up to 100kHz. To acquire these signals for precise power measuring, it is necessary to choose a high sampling rate.

With DEWETRON systems, a sampling rate of up to 10MS/s is possible. This allows exact analysis of the pulse packages of frequency inverters.

An analogue bandwidth of up to 1MHz and DEWETRON galvanic-isolated amplifiers with a bandwidth of up to 2MHz can be applied.

Synchronised measurement data solutions

DEWETRON’s SYNC-CLOCK technology guarantees synchronised measurement data.

Analogue, digital, CAN-bus, GPS, counter and video data is recorded synchronously during the measurement process, meaning no additional work is needed.

Error sources are reduced, saving time and money. The technology produces the highest quality measurement data and maximum efficiency of examination and evaluation.

Current transducers and external sensors for current inputs

DEWETRON’s modular system makes it possible to connect all types of current transducers.

Clients can measure the current directly with shunt-amplifier module (30A peak), or via external sensors (shunt and clamp, etc.) with low-voltage modules. Alternatively, they can connect simple flexcoils, which have an integrator located in the device.

All modules are galvanic isolated with an accuracy of 0.02%.

Synchronised signal inputs

The hardware of the systems provides different signal inputs, including analogue, digital, counter / encoder, video, GPS and various bus systems such as CAN, which are synchronised when recorded.

Almost every sensor can be connected to the DEWETRON system using an anemometer, including voltage, current, rpm, force, torque, noise, vibration, emission data, temperature, pressure and wind speed. This may be expanded to any number of input channels.

Mobile measurement systems for recordings

Mobile measurements require systems with small form factor. DEWETRON systems can be equipped with battery packs that enable measurements under real driving conditions.

The battery packs are hot-swappable, ensuring the arbitrary length of the recordings such as energy consumption at an empty run of a vehicle.

Customised amplifier measurement modules

DEWETRON’s amplifier modules can be customised depending on the application and the sensor.

The input range for every module can be set individually for up to five times better resolution.

Analogue inputs include:

- Voltage

- Current

- Pressure

- Acceleration

- Resistance

- Frequency

- Full, half and quarter bridges

- IEPE® sensors

- Thermocouples

- PT100 to PT1000 and charge

To manage all sensors, a powerful sensor database and TEDS support are integrated directly into the software.

DEWETRON instruments are designed to fulfil the requirements of different specifications and power quality measurement standards, including IEC-61000-4-30 class A, EN50160, IEEE1159 and more.

Measurement services for energy and power applications

Approximately 260,000 measurement channels and more than 12,000 DEWETRON systems are in use worldwide in energy and power, automotive, aerospace and transportation businesses, as well as industry applications.

The company employs more than 200 people and was founded in 1989 in Graz, Austria, with subsidiaries in Germany, China and the US, as well as sales partners in more than 20 countries.

DEWETRON has partnered with Augusta Technology AG and its new major shareholder TKH Group, which is part of an international industry group with a €1.1bn turnover and more than 4,700 staff.