FORCE Technology is one of the leading providers of subsea inspection, documentation and provision of nondestructive testing services.

Automated subsea inspection

Subsea inspection is a fast-growing sector, with the demand increasing for accurate and professional inspection techniques, as well as increasing requirements for documentation of subsea structure conditions. This requirement drives continuous improvement of existing technologies and development of new NDT inspection tools to meet customers’ needs.

FORCE Technology provides comprehensive subsea inspection services to customers in the power industry, using the P-scan system.

Comprehensive inspection of subsea environments

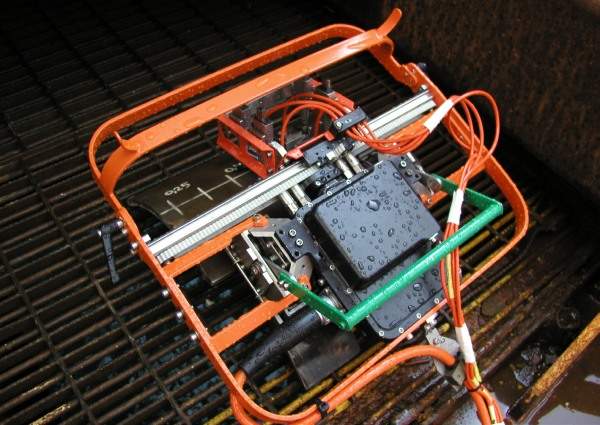

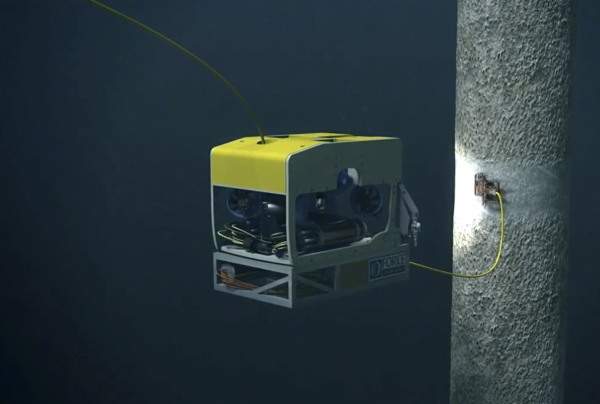

P-scan has proven its excellence in numerous scenarios, but when combined with its wide range of inspection tools and FORCE Technology, even customers with complex and comprehensive inspection requirements can be provided with a solution. All inspection tools can be deployed either by a human diver or by an ROV.

P-scan inspections are a cost-effective solution for ultrasonic and eddy current subsea analysis, as it can withstand rugged conditions and efficiently scan an area with an ROV diver. Its ability to use different technologies, including a flexible magnetic wheel scanner, means P-scan can produce results on numerous applications. Results are displayed in high definition, which provides clients with details of any hidden damage or defects, such as fatigue cracks or corrosion mapping, on their subsea structures.

Automated ultrasound inspection methods for pipe girth welds

In addition to P-scan, FORCE Technology also conducts ultrasound inspections to scan pipe girth welds for hidden defects and damage. Our staff, are fully trained in advanced nondestructive (NDT) services, and provide clients with pre-service inspection on structures in dry locations or in subsea locations at a maximum depth of 1,000m. The inspection process is fast, and with the results digitised, data can be interpreted efficiently and accurately.

NDE inspection and repair services

Given the outcome of an accident on oil and gas or power structures, it is vital to have routine checks and inspections to ensure the structure maintains its architectural integrity. FORCE Technology is one of the leading providers of NDE inspection services in the oil and gas sector, using our F-GRIM technology to detect the presence of fractures, delamination, fatigue cracks, welding issues and wall thickness. F-GRIM is an eddy current based grind and inspection unit that can mitigate cracks in welded joints, grind cracks completely or into a smooth penetration for future repairs.

Subsea inspection of tether string welds

FORCE Technology has experienced an increase in the number of tether string weld inspections throughout platforms in the US, Europe, Africa and the Middle East, and is regularly used in power applications worldwide. Using the P-scan system with tension leg platforms to connect the machine to the base plate and platform of the structure, FORCE Technology can detect whether any service-induced cracks have appeared.