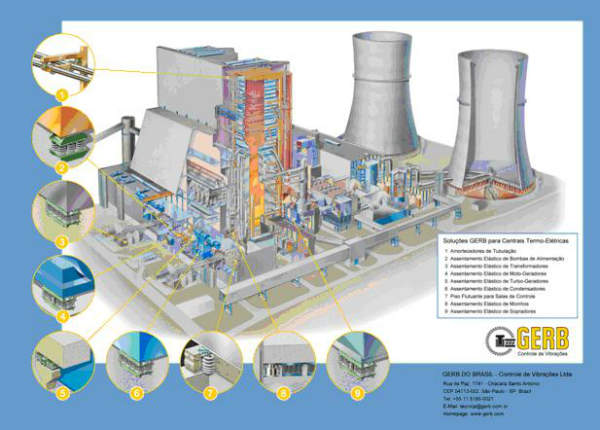

The GERB Group designs, manufactures and supplies vibration control systems based on helical steel springs and viscous fluid dampers, which are combined in a number of ways for different purposes such as: protection of structures and pipework against fatigue, dynamic overloading and even seismic events.

This is in addition to protection of foundations against settlements and overloading, expressive cost savings in the installation of heavy equipment, environmental protection and workspace comfort, service life extension and maintenance reduction of all types of machinery, as well as vibration isolation of sensitive equipment.

The application range of our technology is as wide as the industrial activities themselves, such as metalworking plants, mining activities, offshore operations, chemical facilities and particularly power plants.

Related services such as vibration measurements and forecasts, concept design of foundations and substructures, design aid of pipework systems, installation and construction site supervision, complete the package offered by GERB, allowing for low-cost constructions and safer operation of high-value facilities.

Elastic support for steam and gas turbines

The elastic support system for turbine generator foundations has been widely adopted during the past 30 years by the industry. The GERB system, jointly developed with leading turbine manufacturers, is presently used for turbines with capacities up to 1,300MW worldwide.

Leading manufacturers of turbines and other power plant equipment using the GERB system have the following advantages:

- The turbo generator foundation is dynamically uncoupled from the substructure, allowing the integration of the substructure into the building

- More space below the turbo generator for condensers and piping

- Reduced construction costs

- Shorter construction time

- A significant reduction of on-site structural risks

- Simple adjustment and realignment without shutting off the machine

- Protection of the turbo generator against seismic events

Large conventional gas turbine foundations are prone to problems, especially on bad subsoil, which may lead to operational issues and additional stresses in the foundations. Their elastic support on GERB spring elements will prevent this. Subsequent alignment of the system on spring level without touching the machine is easy and simple, in many cases it is possible even while the gas turbine is running.

The GERB spring system can also protect the gas turbine against earthquakes, if combined with Viscodampers®. Effective vibration controls for gas turbines is also necessary on power barges.

Protection of hot and flexible pipework

GERB Pipework dampers were specifically developed to protect piping systems in power plants, which are normally very flexible so can be vulnerable to various types of abrasion. These elements provide many advantages compared with other dynamic restraints, such as:

- Reduction of operational and shock-induced vibrations

- Immediate reaction to displacements without time lag

- No reactions to thermal expansion

- Maintenance-free with nearly unlimited lifetime

Elastic support for fans and blowers

GERB provides dynamic uncoupling of the fans foundation from the soil by means of spring units equipped with high quality, fatigue free coil springs and non-ageing Viscodampers®, with the following advantages:

- Reduction of the usual massive reinforced concrete cement (RCC) block into a RCC-slab of very limited thickness. The dynamic calculations of the system become very precise

- Very smooth running of the fan, extending components service life, resulting in longer maintenance free periods and higher machine availability

- Design of the substructure for the dead load of the machine and its RCC-deck only

- Piles, wherever required for a conventional foundation, are greatly reduced in quantity or even fully eliminated

Elastic support for motor-generator sets and gas-compressors

On gas or diesel fuelled power plants, uncoupling generators and compressors from the substructure through GERB spring elements and Viscodampers®, as well as an excellent solution to vibration and structure-borne noise problems, provide the following advantages:

- Substantial decrease of foundation mass and size, as well as the size of the generator building

- Groundwater problems are avoided with shallower foundations

- Easy adjustments for substructure settlement

- Protection against seismic events

Elastic support for boiler feed pumps

Boiler feed pumps are basic power plant equipment. If elevated, and not sitting on ground level, the use of GERB systems makes it simple and safe to integrate the pump substructure into the structure of the turbine building, resulting in a highly practical and economical building.

Elastic support for mills, crushers and shredders

These machines are commonly found in power plants using solid fuels, such as coal or agricultural residues. They often require heavy foundations or strong substructures to resist high dynamic loads.

By installing these machines with the GERB systems, the need for heavy foundations and substructures is reduced; machine components such as bearings have their life extended, as well as the machine availability with maintenance is consequently reduced.

Vibration control solutions for power plants

In the previous sections some of the most common applications of GERB solutions for power plants were summarised. Although regardless of what the equipment may be, GERB has the solution. We have proven throughout our 100 year company history that vibrations can be controlled wherever they arise.

GERB do Brasil Ltda, the Brazilian branch of the group with its engineering office and factory located in Sao Paulo, was established in 1992 and today supplies all of Latin America with GERB solutions for every vibration need.

Please contact us. We will be glad to help.