The growing demand for electricity, climate change concerns, and technology development are some of the major factors influencing the steam turbine market.

Cleaner Power Generation: Evolving Manufacturing Practices in the Steam Turbine Industry

Evolving manufacturing practices are contributing to the fabrication of new thermal-based power generation systems with reduced environmental pollution to enhance market acceptance.

Advanced Technologies Transforming Steam Turbine Operations

Various new technologies, such as Integrated Gasification and Combined-Cycle (IGCC), carbon capture and storage (CCS), supercritical and ultra-critical power generation, and carbon sequestration, which were developed over the past decade, are a lot cleaner and make thermal power generation more acceptable within the confines of established policies and regulations. These technologies will go a long way in helping turbine manufacturers to continue operations, particularly steam turbine manufacturers.

The modernization of coal power plants in countries across the world requires cooperation and extensive technology transfer via licenses and joint ventures with international equipment suppliers. Chinese manufacturers advanced the technical quality of their products to such an extent that they can capture significant export opportunities, especially as their products are more cost-competitive than the products of manufacturers in other countries.

Major Players in the Global Steam Turbine Manufacturing Market

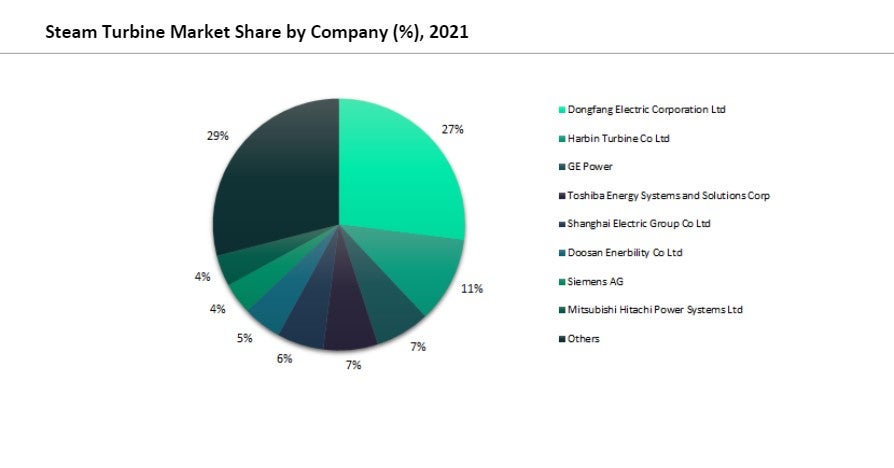

According to GlobalData, China accounts for the largest share of the market, followed by India. The major players in the steam turbine manufacturing market include Dongfang Electric Corporation Limited, Harbin Electric Company Limited, GE Power, Toshiba Energy Systems and Solutions Corp, Shanghai Electric Group Co Ltd, Doosan Enerbility Co Ltd, Siemens AG, and Mitsubishi Hitachi Power Systems Ltd. Combined, these companies accounted for over 70% of the steam turbine market in 2021.

Other Notable Suppliers in the Steam Turbine Industry

Other significant suppliers are Power Machines, Bharat Heavy Electricals Ltd., Fuji Electric Co Ltd, Ansaldo Energia SpA, Kawasaki Heavy Industries Ltd, Harbin Steam Turbine Factory Co Ltd, Beijing Beizhong Steam Turbine Generator Co Ltd, and L&T-MHI Power Turbine Generators Pvt Ltd.

Finding the Best Steam Turbine Manufacturers

Power Technology has listed leading manufacturers of steam turbines based on both its experience in the sector and research carried out by GlobalData.

The information contained within the download document is designed for production managers, procurement managers, maintenance managers, quality control managers, marketing managers, research & development managers, and supply chain managers, and the many other roles responsible for the purchase of steam turbines.

The free Buyers Guide is available to download and contains detailed information on the suppliers and their product lines, alongside contact details to aid your purchasing decision.

Note: GlobalData, the leading provider of industry intelligence, is the parent company of Power-Technology.com and provided the underlying data, research, and analysis used to produce this article.

For full details (including contact details) on the leading companies within this space, download the free Buyer’s Guide below:

Frequently asked questions

-

What are steam turbines used for in the power industry?

Steam turbines convert thermal energy from pressurised steam into mechanical energy to generate electricity. They are integral to thermal power plants, including coal, gas, and nuclear power stations, as well as renewable energy facilities such as biomass and concentrated solar power plants. The mechanical energy produced is used to rotate generators, producing electrical power.

-

How do steam turbines contribute to cleaner energy production?

Modern steam turbines, integrated with technologies like Integrated Gasification Combined Cycle (IGCC) and carbon capture systems, reduce emissions and improve energy efficiency. These advancements help meet stringent environmental regulations, making thermal power generation more sustainable and acceptable.

-

What are the main types of steam turbines used in power generation?

There are three primary types of steam turbines: condensing, non-condensing, and extraction turbines. Condensing turbines are the most common in large-scale power plants, converting maximum energy into electricity by condensing exhaust steam. Non-condensing turbines are used in industrial applications, while extraction turbines allow for more flexible power generation.

-

Which companies lead the steam turbine manufacturing industry?

Global leaders in steam turbine manufacturing include companies such as GE Power, Siemens, Mitsubishi Power, and Doosan Enerbility. These companies develop advanced turbine technologies for various applications, offering solutions that enhance efficiency and reduce emissions in power generation.

-

How has steam turbine technology evolved in recent years?

Steam turbine technology has evolved with the development of supercritical and ultra-supercritical turbines, which operate at higher temperatures and pressures for greater efficiency. Carbon capture and storage (CCS) integration has also become more prevalent, helping to reduce the environmental impact of thermal power generation.