Engine manufacturers in the power sector are having to respond to growing concerns over emissions from coal-fired power plants. Countries across the world are aiming to reduce dependence on coal.

This is reflected in the move to switch to renewable resources and natural gas for power generation in order to achieve climate targets and reduce carbon emissions.

Governments around the globe are also implementing strict regulations to meet this requirement.

Cumulative installed capacity from thermal energy sources was 4,483GW in 2021 and is projected to reach 4,774GW in 2026.

Coal-fired power plants accounted for 2,160GW of the cumulative installed capacity in 2021, and gas and oil-fired power plants for 1,996GW and 327GW, respectively.

By 2026, coal-fired power plants are expected to continue to contribute most of the global thermal cumulative installed capacity of 2,235GW, followed by gas and oil power plants with 2,218GW and 321GW, respectively.

By region, Asia-Pacific accounted for 49.5% of the global thermal cumulative installed capacity, followed by North America, Europe, the Middle East and Africa, and South and Central America with 20.62%, 15.26%, 11.63%, and 2.99%, respectively.

For the global cumulative installed capacity of engines, Asia-Pacific accounted for approximately 29.7% in 2021, followed by South and Central America with 25.5%. The Middle East and Africa, North America, and Europe accounted for 19.5%, 13.2%, and 12.2%, respectively.

Industry-leading Engine Manufacturers

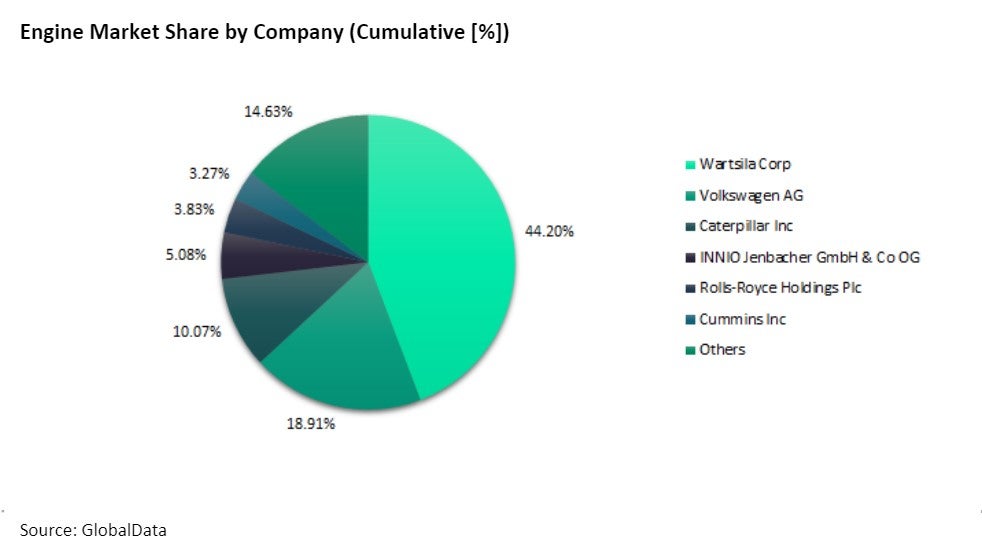

The major engine manufacturers include Wartsila Corp, Volkswagen AG, Caterpillar Inc, INNIO Jenbacher GmbH & Co OG, Rolls-Royce Holdings Plc, and Cummins Inc.

These companies together held more than 85% cumulative share in the global engine market, with the remainder shared by local and other international engine suppliers.

Other significant engine manufacturers are Korea Shipbuilding & Offshore Engineering Co Ltd, Sulzer Ltd, General Electric Co, Langley Holdings Plc, Deutz AG, Niigata Power Systems Co Ltd, Mitsubishi Heavy Industries Ltd, Kawasaki Heavy Industries Ltd, and SEMT Pielstick.

Finding the best engine supplier

Power Technology has listed leading engine manufacturers based on both its experience in the sector and research carried out by GlobalData.

Within our download document we have included a wealth of important industry information.

This content is of particular interest and use to production managers, procurement managers, maintenance managers, quality control managers, marketing managers, research & development managers, and supply chain managers, and the many other roles responsible for the purchase of engines.

Our extensive and free Buyers Guide is available to download. It contains a range of highly detailed information on the engine suppliers and their product lines, alongside contact details to aid your purchasing decision.

FAQs

What types of engines are used in the power industry?

The power industry relies on engines such as gas turbines, diesel engines, and reciprocating internal combustion engines.

These engines are used in power generation, backup power systems, and energy storage solutions, providing high efficiency and reliability for electricity production.

How do gas engines contribute to energy efficiency?

Gas engines are highly efficient in converting natural gas into electricity, making them ideal for combined heat and power (CHP) plants.

They reduce energy waste by capturing excess heat for other uses, boosting overall energy efficiency.

Why is engine maintenance important for power generation?

Regular engine maintenance is crucial for ensuring optimal performance and preventing costly downtimes.

It helps identify potential issues early, reduces wear and tear, and extends the operational lifespan of the engine, ensuring continuous and reliable power generation.

How are engine manufacturers adapting to renewable energy trends?

Engine manufacturers are increasingly focusing on engines that can integrate with renewable energy systems, such as gas engines capable of using biogas or hydrogen.

This helps reduce emissions and supports the transition to cleaner energy sources.

What role do engines play in backup power systems?

Engines, particularly diesel and gas engines, provide critical backup power for hospitals, data centres, and other essential services.

These systems ensure continuous operation during power outages, offering reliability and rapid response times in emergency situations.

Note: GlobalData, the leading provider of industry intelligence, is the parent company of Power-Technology.com and provided the underlying data, research, and analysis used to produce this article.