Researchers at the University of Cambridge have developed algae-powered fuel cells that are five times more efficient than existing plant and algal models, as well as being potentially more cost-effective to produce and practical to use.

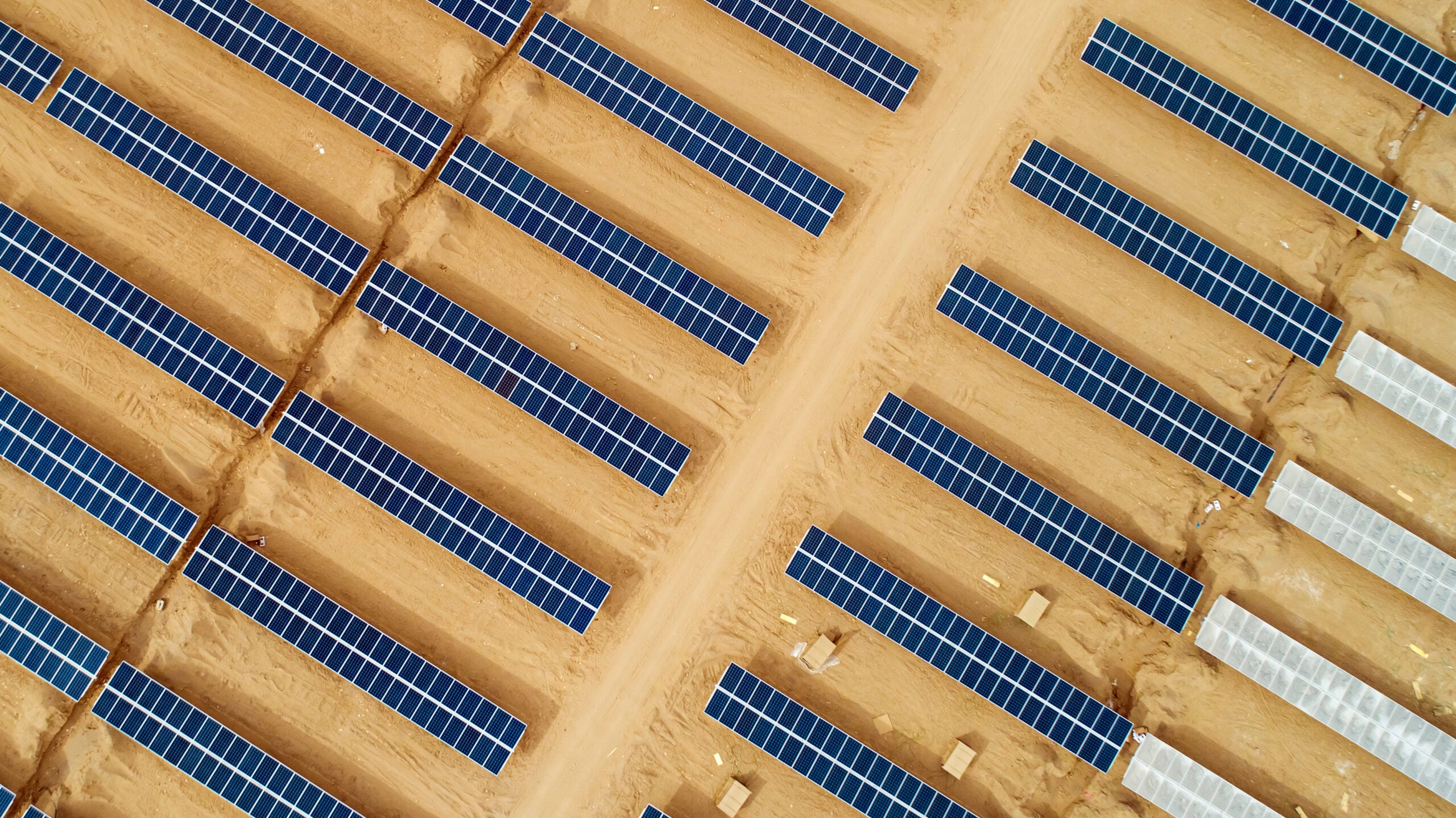

The technology builds upon existing biophotovoltaics – biological solar cells – that have emerged as a low-cost alternative renewable to solar panels.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataThe process behind biophotovolatics (BPVs) is simple. During photosynthesis, algae produces electrons. Some of these electrons can then be harnessed to provide electric current to power devices.

Currently, all BPVs have both charging (light harvesting and electron generation) and power delivery (transfer to the electrical circuit) in a single compartment. The result is that electrons generate current as soon as they have been harnessed, and therefore power cannot be stored.

However, the new technology addresses this problem with a two-chamber system, where electron generation and power conversion are separated.

“Charging and power delivery often have conflicting requirements,” explained Kadi Liis Saar, of the Department of Chemistry.

“For example, the charging unit needs to be exposed to sunlight to allow efficient charging, whereas the power delivery part does not require exposure to light but should be effective at converting the electrons to current with minimal losses.”

Building a two-chamber system allowed the researchers to design the two units independently and through this optimise the performance of the processes simultaneously.

“Separating out charging and power delivery meant we were able to enhance the performance of the power delivery unit through miniaturisation,” explained Professor Tuomas Knowles from the Department of Chemistry and the Cavendish Laboratory.

“At miniature scales, fluids behave very differently, enabling us to design cells that are more efficient, with lower internal resistance and decreased electrical losses.”

The team used genetically modified algae to carry mutations that enable the cells to minimise power wastage. When combined with the two-chamber system, the researchers were able to build a biophotovoltaic cell with a power density of 0.5W/m2 – five times that of their previous design.

While this is still only around a tenth of the power density provided by conventional solar fuel cells, these new BPVs have several attractive features, according to the researchers.

“While conventional silicon-based solar cells are more efficient than algae-powered cells in the fraction of the sun’s energy they turn to electrical energy, there are attractive possibilities with other types of materials,” said Professor Christopher Howe from the Department of Biochemistry.

“In particular, because algae grow and divide naturally, systems based on them may require less energy investment and can be produced in a decentralised fashion.”

Algae-powered fuel cells are unlikely to generate enough electricity to power a grid system, but they may be particularly useful in areas such as rural Africa, where sunlight is in abundance but there is no existing electric grid system. Additionally, BVPs could be used directly by local communities, as opposed to semiconductor-based solar cells, which are usually produced in dedicated facilities away from where they are used.

“This a big step forward in the search for alternative, greener fuels,” said Dr Paolo Bombelli, from the Department of Biochemistry. “We believe these developments will bring algal-based systems closer to practical implementation.”