Kopar, a Finnish engineering and manufacturing company, specialises in mechanical water screening and filtration systems. Kopar’s water treatment equipment consists of automated bar screens, travelling basket filters and drum basket filters.

Water screening benefits all industries where large amounts of cooling or process water are needed. Kopar’s clientele include:

- Power plants, especially condensing power plants

- Oil refineries

- Pulp and paper mills

- Chemical process plants

The mechanical filters supplied by Kopar are also used as the first process phase when surface water is pre-filtrated in municipal or industrial high-quality water plants.

BAR SCREENS

The grid of the bar screens supplied by Kopar is designed to prevent clogging. The trash collected on the grid is automatically removed at intervals by the cleaning rake. The cleaning phase of the bar screen is switched on by pressure sensors or timers.

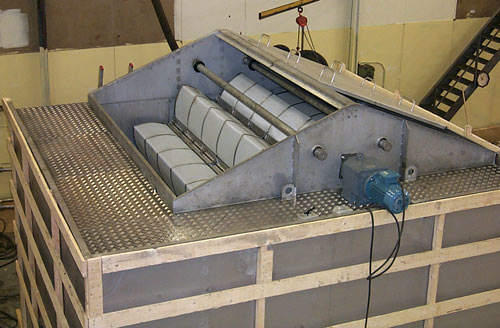

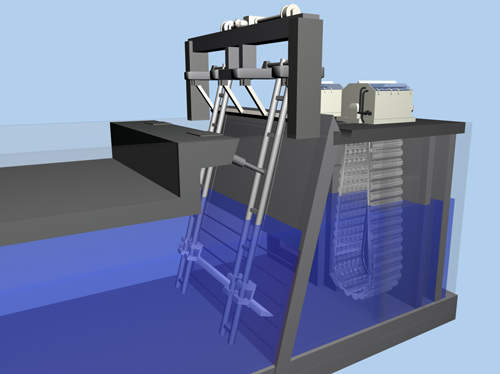

TRAVELLING BASKET FILTERS

If water is taken directly from a river, lake or sea by gravity flow, travelling basket filters are recommended for the treatment, especially if there are large fluctuations in the water level.

The filter screen has a mesh size from 0.2mm to 3mm, depending on the purpose. The screen is made of stainless steel or plastic material. The travelling basket filters supplied by Kopar have a capacity of 1,800m³/h to 50,000m³/h.

DRUM BASKET FILTERS

Drum basket filters are used when a high degree of mechanical purification is required.

These filters have proven their reliability in a large number of installations worldwide. They are able to separate particles down to 20µm, and the mesh of the filters is selected according to the requirement.

The largest drum basket filters supplied by Kopar have a capacity of 4,800m³/h.

DRAG CHAIN CONVEYORS

Kopar has a long history as a manufacturer of process and material handling equipment for the non-ferrous smelter industry. Kopar drag chain conveyors are ideal in transporting hot powdered and dusty materials. Drag chain conveyors are built with forged conveyor chains, and are the correct choice for transporting hot and abrasive materials.

Kopar’s range of equipment for the smelter industry also includes anode furnaces, converters, rotary dryers and granulation plants.