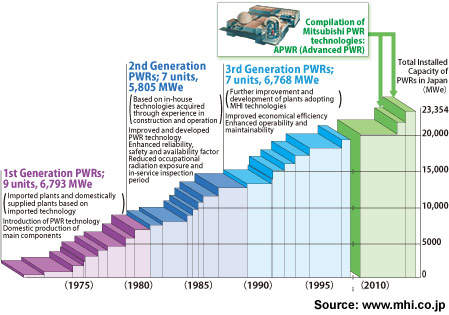

The 912MW Tomari-3 became the 54th commercial nuclear plant in Japan when it commenced operations in December 2009. It was constructed by Hokkaido Electric Power on the country’s most northerly island. The steam generator is the 100th supplied by Mitsubishi Heavy Industries, and increased the total installed gross capacity of the Tomari plant to above 2GW.

The two existing 550MW Tomari units 1 and 2 are both MHI PWRs, and started commercial operation in 1989 and 1991.

High utilisation of the Tomari power station means it has generated around 30% of the total electricity consumption of Hokkaido. The expansion was estimated to cost around ¥290bn ($2.5bn).

The plant began commercial operations on 22 December 2009. Trial operations were launched by Hokkaido in March 2009. The reactor reached criticality on 3 March 2009.

The company has also received approval from the Hokkaido government and four neighbouring municipalities for using MOX (mixed plutonium-uranium oxide) fuel at the plant. MOX fuel assemblies are scheduled to be implemented in Q2 2012.

Adds to existing PWRs

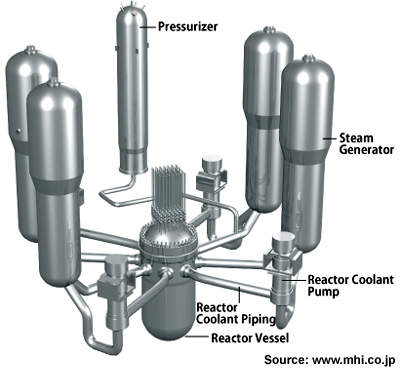

Pressurised water reactors (PWR) are the world’s most common type of nuclear reactor and are a form of light water reactor. The basic design concept of the PWR is simple: pressurised water is used as the reactor coolant, with the reactor and turbine systems being separated by steam generators to give an indirect cycle system.

The reactor (primary) system collects heat generated in the reactor and the turbine (secondary) system produces electric power with steam generated. Pressure in the primary system prevents the high-temperature primary cooling water from boiling. Because the primary and secondary systems are separated, secondary steam through the turbine is not contaminated by radioactive materials.

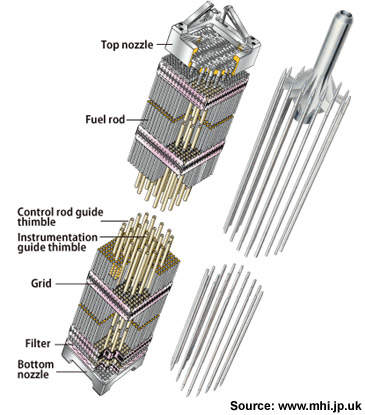

The high moderator density makes it possible to minimise the fuel rod pitch and produce a compact reactor core design. The absence of bulk boiling in the core limits cladding corrosion and thereby increases fuel reliability. An open-lattice fuel assembly design contributes to the economical use of neutrons and results in excellent fuel economy.

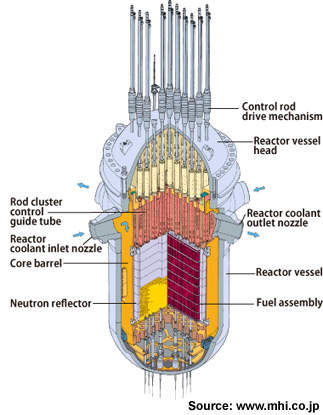

The self-control mechanisms are inherent and a safe shutdown capability is ensured by gravity insertion of control rods in an emergency. The core cooling with heat-removal capability of the secondary system ensures inherent reactor safety in an emergency. The lower centre-of-gravity plant design gives seismic resistance.

Reactor vessel and steam generator

The reactor vessel consists of fuel and core support structures. It forms a reactor coolant pressure boundary withstanding high temperatures and high pressures during normal operation, abnormal transient condition and fast-neutron embrittlement.

The steam generator is a vertical U-tube heat exchanger that converts the thermal energy generated in the reactor vessel to the steam, and transfers the steam to the turbine system. The steam generator is located higher than the inlet-outlet nozzles of the reactor vessel, to enable the removal of decay heat by natural circulation after reactor shutdown.

A typical steam generator is about 21m high, up to 5m in diameter and weighs around 330t (330,000kg). Typically they house around 3,400 inverted U-shaped heat transfer tubes, 20mm in exterior diameter and 20m in length.

Design and manufacturing needs 1/100mm level accuracy for the huge structure. The Tomari-3 Steam Generator was made at MHI’s Kobe Shipyard & Machinery Works.

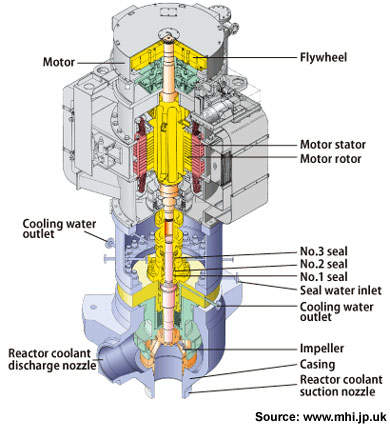

Reactor coolant and pump, and pressuriser

The reactor coolant pump circulates the reactor coolant to remove heat from the reactor core at a constant flow rate. The pressuriser controls the reactor coolant system pressure constant, actuating electrical heater, spray valve and relief valve. The reactor coolant piping interconnects the reactor vessel, steam generator and reactor coolant pump in a circulating loop configuration.

As reported on Power Technology in July 2007, Hokkaido experienced a minor fire following a devastating earthquake eight days before. No injuries were reported, with no danger of a radiation leak.

There were, however, claims that the fire was started deliberately. In 1995 there was a fire in a radioactive waste tank and in 2003 a reactor was shut following a leak in a coolant tank.