The Montgomery Biomass Power Plant (MBPP) is located 70 miles north-west of New York in Orange County, US. It will be the first biomass gasification facility in the country to utilise municipal solid waste (MSW) for the production of electricity.

The plant is being designed and built by Taylor Biomass Energy (TBE) in two phases. It will generate 20MW of clean and renewable biomass electricity using Taylor’s Gasification Process technology. It will produce enough power to light 27,000 homes, assuming a supply rate of 500kw/h per month, per house.

The plant is being built on a 95-acre site located at Neely town road in Montgomery, New York. Construction began in December 2010 and is expected to be completed by 2012. The project will create 400 temporary jobs during construction and 80 permanent jobs upon completion.

Project finance

The biomass power project is expected to cost approximately $150m. TBE arranged $20m for the project through private investments. The company requested that the US Department of Energy (DOE) to finance the remaining $130m required to complete the innovative green energy project.

In September 2009, TBE applied for the first phase of the DOE loan guarantee programme under the 2009 American Recovery and Reinvestment Act. The second phase application was submitted in January 2010.

The DOE granted $100m for the project in August 2010. TBE will additionally receive 30% ($30m) through federal tax credit made available for renewable energy projects upon commencing production at the plant.

Plant details

The plant is being built at an existing site of the Taylor Recycling Facility (TRF), which will render municipal solid waste to the Biomass Plant. The capacity of the TRF will be increased from 307t per day (tpd) of construction and demolition (C&D) waste and 100tpd of wood waste to 450tpd of C&D Waste, 100tpd of wood waste and 500tpd of municipal solid waste.

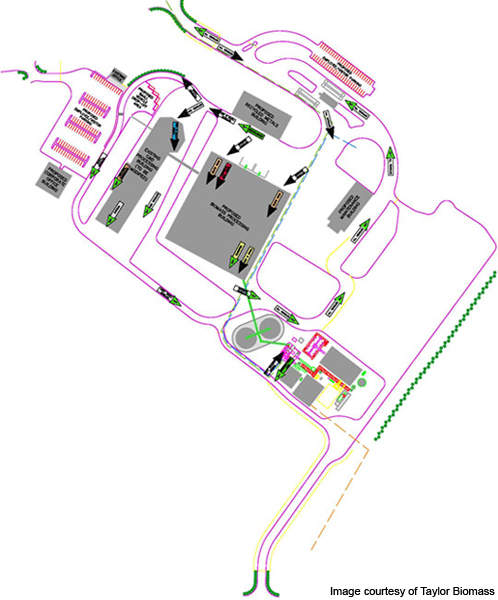

The MBPP will encompass a 7,342ft² two-storey office building, a 15,042ft² equipment maintenance building and an 119,520ft² post collection separation facility, which generates biomass feedstock for the gasifier. It will also feature a 14,375ft² processing structure for supplying additional wood waste and biomass.

A 20,000ft² recyclables handling and recovery structure, a three-storey 30,000ft² corporate office building, two biomass storage silos, a gasification unit, and a power generation pad are also being built. The existing 4,104ft² office building will be reconstructed to serve as additional office space.

Multiple vehicle weigh stations will be built to optimise and carry the flow of traffic.

Montgomery biomass reactors

The plant will use three fluidised-bed reactors including a gasification reactor, a combustion reactor and a gas conditioning reactor. The gasification and combustion reactors will be of the circulating type while the gas conditioning reactor will be of the bubbling type.

Process technology

The MBPP will utilise TBE’s gasification process for transforming MSW into electricity. The process, for which a patent is pending, involves sorting, separating and gasification processes innovated by Taylor.

The Taylor sorting and separating process (TSSP) starts by receiving waste such as paper, fibre, wood, food residuals, leather and some textiles. TSSP removes the unwanted waste and produces appropriate PVC mixed with biomass fraction. The PVC will be eliminated using advance infrared technology thereby generating biomass feedstock, which can be stored in two biomass storage silos for a maximum of five days.

In the Taylor gasification process the biomass feedstock from the TSSP and heat transfer material will be fed to the gasification reactor, which heats up the feedstock to 1,500°F and converts it into medium calorific value (MCV) synthetic gas plus char.

The resultant gas (synthetic gas plus char) will be transferred to the combustion reactor into which air is introduced to react with the char. The heat in the combustion reactor is further increased to approximately 1,800°F producing carbon-free ash.

Re-heated solids will be sorted from the flue gas and returned to the gasification reactor. Carbon-free ash will be removed from the gasification reactor and the resultant synthetic gas with a mixture of tars will be fed as input to the gas conditioning reactor.

The gas conditioning reactor breaks down the tars (hydrocarbons) into lower molecular weight compounds (hydrogen, carbon monoxide and methane) by heating the gas up to 1800°F. These compounds will be gathered from final synthetic gas and transferred to gas turbines with generators for producing electricity.

These gas turbines will be supplied by Solar Turbines, a subsidiary of Caterpillar.

Power grid-network

The power will be transmitted to the local Central Hudson Gas and Electric Corporation Grid System through a 69kv electric transmission line installed at the site.