The 1,300MW South Bangkok phase one combined-cycle power plant is intended to replace Electricity Generating Authority of Thailand’s (EGAT) existing thermal power plant located 20km south of Bangkok in the Samut Prakan province, Thailand.

Construction of the replacement power plant is expected to commence in the fourth quarter of 2017, while operations are currently slated to begin in 2019.

The $550m project is being developed under the Government of Thailand’s Power Development Plan, which aims to improve the reliability of the country’s power system and introduce clean power generation facilities.

EGAT is planning to purchase electricity generated by the plant to supply power to approximately 1.5 million households.

The plant is anticipated to address the country’s increasing demand for energy, while supporting the industrial and economic growth of the metropolitan areas within the wider Bangkok region.

It will also provide a safe, environmentally friendly and affordable solution to meet Thailand’s growing energy demands.

South Bangkok combined-cycle power plant make-up

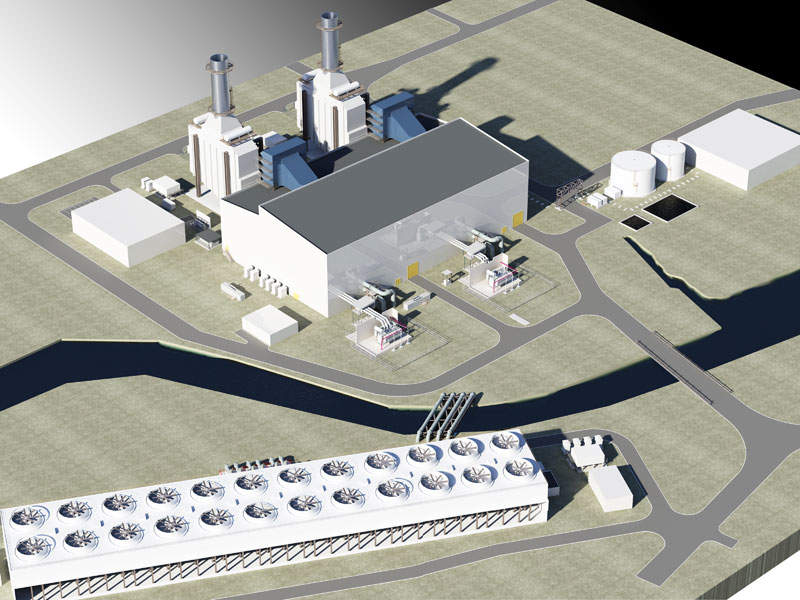

The South Bangkok combined-cycle power plant will cover an area of 35ha in district of Bang Prong, Mueang.

It will be developed in two phases, with the first phase comprising the replacement of units 1-5 with two new units.

The second phase will include the replacement of the power plant’s remaining units.

Both of the units in phase one will be arranged in a single-shaft configuration developed by Siemens, which will see the major components arranged in a single train formation.

The system configuration is expected to result in a higher degree of efficiency with shorter start-up times, while offering the flexibility to adapt to quick load changes.

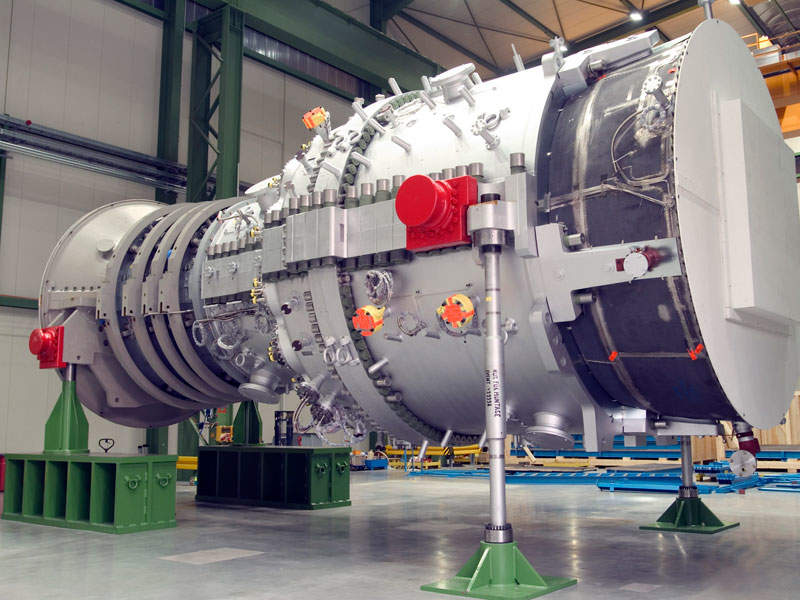

Each unit will include a SGT5-8000 H-class gas turbine, SGen5-3000W generator, SST5-5000 steam turbine and a heat recovery steam generator operated by a SPPA-T3000 control system.

Details of the turbines and generators at South Bangkok CCPP

The SGT5-8000H is a 50Hz heavy-duty gas turbine with an output capacity of 660MW and an efficiency rate of more than 60.75%.

The turbine is considered a low-emission solution that delivers high serviceability, reliability and availability.

SGen5-3000W units are hydrogen-cooled, two-pole generators with water-cooled stator windings rated up to 1,270MVA for combined-cycle operations.

The efficiency of the generators is high as the frictional losses are low.

The SST5-5000-series steam turbine comprises a high / intermediate pressure cylinder and a double-flow low-pressure cylinder.

It is designed for short start-up times and high operational performance.

Contractors involved

EGAT contracted a consortium of Marubeni Corporation, Siemens and Siemens Limited Thailand for the plant’s construction.

Siemens and Siemens Limited Thailand are set to supply the turbines and generators, while the heat recovery steam generators will be engineered by NEM Energy.

Marubeni is providing the balance of plant equipment and conducting a variety of civil works, including the construction of two chambers, substations, chimneys and a gas storage area.

The corporation will also be responsible for the installation and setup of the cooling towers, compressors and gas loading / unloading facilities, as well as the site’s high-voltage gas-insulated switchyard.

South Bangkok power plant history

The construction, installation and commissioning of the original South Bangkok thermal power plant took place between 1968 and 1976.

The plant initially used fuel oil to generate power but was eventually modified to a combined-cycle configuration following the discovery of natural gas in the Gulf of Thailand.

EGAT ordered the decommissioning of units 1-5 of the thermal power plant to give way for the phase one replacement and development work in 2015.

Units 1-3 were decommissioned in July 2008.