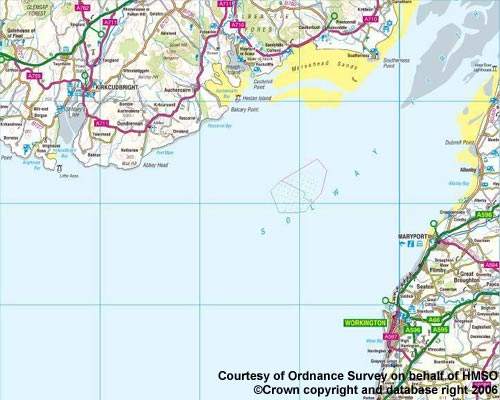

Robin Rigg offshore wind farm is located in the Solway Firth on the Scottish side of the Scottish / English Border. The 180MW wind farm is one of the largest in the UK. Construction of the project was completed in September 2009 and it was commissioned in April 2010. The plant became operational after much delay due to bad weather conditions. It was initially planned for completion in October 2008.

Robin Rigg required an investment of about €500m. It consists of 60 V90-3MW Vestas turbines. The 60 turbines are supported on foundations which typically extend 30 to 40m into the sea bed. Each turbine has an 80m hub height and generates 3MW. Robin Rigg is now powering nearly 120,000 homes and will be displacing 235,000t of carbon dioxide every year.

Construction

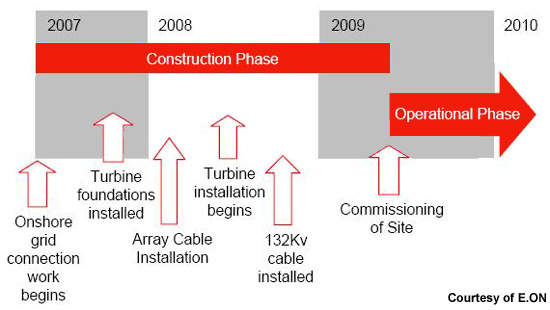

In December 2006, MT Hojgaard was awarded the turnkey contract for the design, supply and installation of the 60 Robin Rigg and two substation foundations. Design and fabrication took place during 2007, with installation during 2008. The two substations were transported to Barrow in Furness in the autumn of 2007 to be fitted with main transformers and other mechanical and electrical equipment.

The “MV Resolution” carried out geotechnical surveys, while the Jack Up Barge “Lisa A” installed the foundations. The “Lisa A” installed the monopiles (35m-long pipes, 4.3m in diameter) and fitted the Transition Pieces.

The turbine foundations were delivered directly to the offshore site from Belgium during the summer of 2007. The turbines themselves were assembled in Belfast and delivered offshore for installation in the summer of 2008. The offshore substation platforms were fitted out with electrical equipment in Barrow-in-Furness. The Port of Workington was selected as the base for the operation and maintenance (O&M) of the wind farm for its 20-year operational life.

Turbines

The Vestas V90-3MW is a three-bladed upwind turbine, introduced in 2002. Vestas has so far installed more than 500 turbines around the world. Every aspect of the design was rethought to reduce the cost per kWh; the lighter the turbine, the lower the cost of production, materials, transport and installation.

Despite the larger rotor and generator, the V90-3MW weighs less than the V80-2MW turbine.

The V90 introduces a lighter, stronger tower and a new nacelle design which produces more power from less weight.

The blade structure, which is different from previous versions, incorporates new materials and a revised blade profile design. The turbine features pitch control, with a doubly fed 50Hz induction generator. It also has an oil-cooled generator and a new compact gearbox that connects directly to the hub.

Grid network

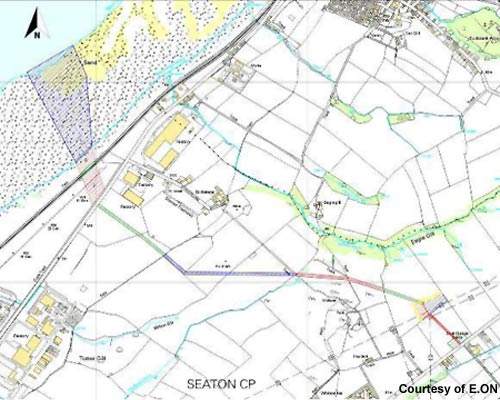

Robin Rigg is around 9km from the nearest landfall on the coast of Dumfries and Galloway at Balcary Point, and almost equidistant from the Cumbrian Coast. Each of the 60 turbines are connected to the offshore substations by subsea cables. These substations, in turn, are connected to the local electricity distribution system across two 132kV cables. The cables come ashore near Seaton, Cumbria where they travel about 2km inland to the new onshore substation.

Development

Solway Offshore Limited and Offshore Energy Resources Ltd originally applied in June 2002 to the Scottish Ministers for Section 36 consent to construct the wind farm.

Consent was granted in March 2003 on behalf of Babcock & Brown and TXU Europe.

Natural Power helped identify and scope the site, provided initial estimations of the available energy resource and identified technical and environmental constraints and issues.

It then helped take the project from concept to consented project with appropriate land agreements, grid connection offer and planning permits in place.

The project was acquired by E.ON UK Renewables in autumn 2003 and Natural Power continued its work with E.ON during the pre-construction phase. Natural Power is also currently managing the Construction Phase Environmental Monitoring Programme for E.ON.