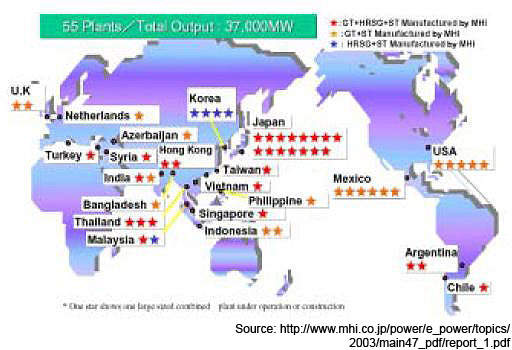

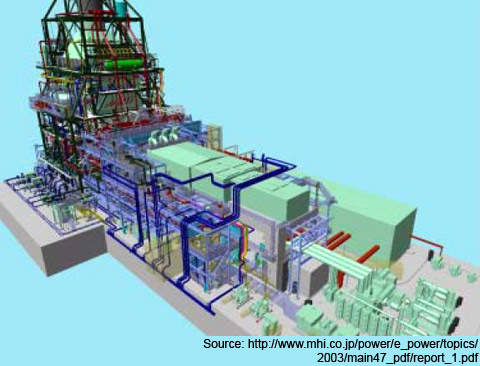

The Qianwan LNG No.2 power plant started up in January 2007, adding another 1,170MW to the Chinese grid. The ¥4bn ($480m) Qianwan plant, on Dachan Island in Nanshan District, has three 390MW M701F single-shaft gas turbines.

Qianwan belongs to Shenzhen Guangqian Electric Power Co, itself owned by Guangdong Electric Power Holding Company (GEPHC). The plant will help to relieve Shenzhen's serious power shortages.

THREE MHI M701F TURBINES

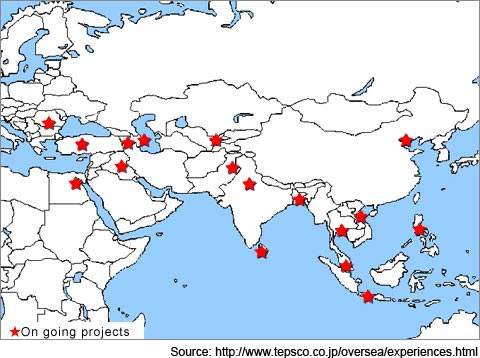

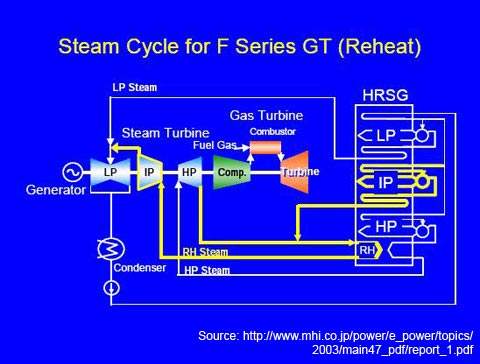

The three M701F single-shaft units use gas turbines that were collaboratively produced with the DongFang Turbine Co, so helping transfer the gas turbine technology. MHI supplied the key components of the turbines (rotors, blades, combustors), and the DongFang Turbine made and assembled other gas turbine components, as well as supplying steam turbines and peripheral equipment. Tokyo Electric Power Services provided engineering services for the plant.

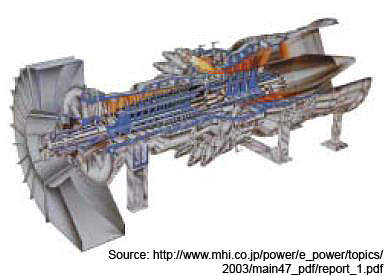

Mitsubishi's F-Series turbines are among the world's most used gas turbine designs. They have a firing temperature of 1,400°C (uprated from 1,350°C).

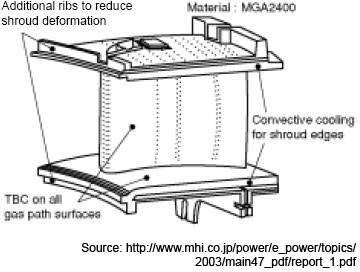

Advanced cooling of items like rotating blades and stationary vanes has held material temperatures down to those of the company's D-Series turbine levels.

MHI's pre-mix DLN combustor has within 15ppm NOx emissions. Active online combustor sensors protect against combustion flame instabilities.

Turbine design features include two-bearing single-shaft construction, cold-end power drive and axial exhaust. The four-stage turbines have a double shell casing construction to prevent rubbing between stationary and rotating parts. High-strength durable and repairable hot gas path materials are used instead of expensive single crystal parts.

MHI's compressor shaft has radial pins at the disc contact surface to ensure proper torque transfer. The rotating blade can be removed without disassembling the rotor. The rotor cooling air is extracted from the compressor discharge and cooled in an external cooler. Heat dissipated at the cooler is effectively recovered as fuel heating to obtain better thermal efficiency.

DEBATE CONTINUES OVER NATURAL GAS VERSUS COAL PLANTS

Coal-fired power plants have been blamed for much of the worsening air quality in the Chinese Delta Pearl River region, and LNG produces much lower levels of pollutants. Use and production of natural gas in China has been growing steadily, and is estimated to grow at above 10% over the next 15 years. That means it will reach about 10% of China's total supply by 1020. China cannot meet this demand itself, so is building LNG terminals in ports around the coast, like at Guangdong for imports.

However, there is still debate in the country on the advisability of long-term commitment to gas-fired power stations. As fossil fuels, they still emit carbon dioxide, although not as much as coal. Gas is scarcer in China and costs more than coal. China will therefore have to compete in the world market for supplies. Gas-powered stations at the moment, too, have heavy reliance on imported equipment.

QIANWAN FEASIBILITY STUDY APPROVED

A feasibility study report for Qianwan originally planned three 350MW generators, but these were increased to 390MW. GEPHC was responsible for Qianwan's construction, and the company has since increased its equity interest from a 19% planned share to 40%.

Capital injection by Guangdong Electric Power Holding Company and Yudean Group was RMB400m and RMB590m respectively.

The first of China's commercial gas-fired plants was connected in June 2005: the three 390MW unit CCGT is in Hangzhou, capital of Zhejiang.

Besides Qianwan, China's Guangdong Province is now adding two more CCGT plants: the Huizhou LNG plant and Shenzhen Energy Group plant. In total, the three plants have nine GTCC units.

There are now over 20 gas-fired plants complete or in construction, generating almost 20GW. Two LNG terminals are under construction in Guangdong and Fujian, with another 15 or so planned, although the high price of gas has cast some doubt whether all will be completed.