The Mangdechhu hydroelectric project (HEPP) is a 720MW run-of-river power plant built on the Mangdechhu River in Trongsa Dzongkhag District, central Bhutan. A part of the Indian Government and the Royal Government of Bhutan, Mangdechhu Hydroelectric Project Authority (MHPA), developed the project.

Mangdechhu is one of the ten hydroelectric projects being developed as part of the Royal Government of Bhutan’s initiative to generate 10GW of hydropower by 2020 with support from the Indian Government. The two governments signed an agreement for the construction of Mangdechhu HEPP for Rs28.96bn ($434m) in April 2010.

The Indian Government funded the project through a 70% loan and a 30% grant. India approved a revised cost estimate of Rs40.20bn ($602.7m) for the project in 2016.

The construction of the hydropower project began in June 2012. The first of the four power plant units was commissioned in June 2019, while the second unit was commissioned in July 2019. The hydropower project was officially inaugurated in August 2019. PTC India and Druk Green Power Corporation signed a power purchase agreement (PPA) for Mangdechhu Hydroelectric project in August 2019.

The project is estimated to generate 2,923GW/h of electricity and neutralise 2.2Mt of CO₂ from the atmosphere every year.

Mangdechhu hydroelectric power plant details

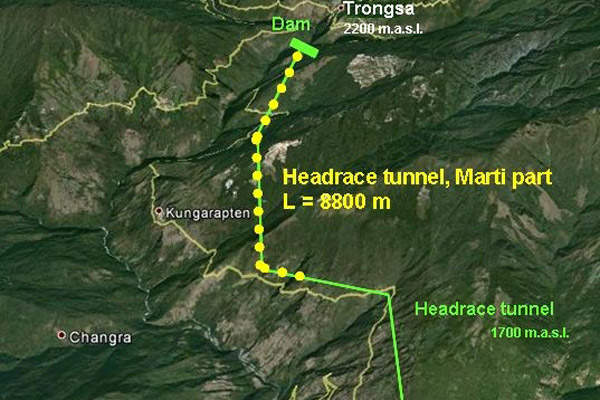

The Mangdechhu run-of-river hydroelectric power plant has a 101.5m-high concrete gravity dam from the deepest foundation level, two intake tunnels, measuring 196m and 150m-long respectively and a horseshoe-shaped 13.54km-long headrace tunnel with a 6.5m diameter. The tunnel can discharge 118m³ of water a second.

The 152m-high surge shaft has a diameter of 13.5m. Water is fed to the underground powerhouse through two steel-lined pressure shafts that are 1,853m and 3.5m-long in diameter.

Bharat Heavy Electricals Limited (BHEL) supplied the underground powerhouse of the Bhutanese hydroelectric project with four 180MW Pelton turbines. The main cavern of the underground powerhouse is 53m-high and 231m-long.

Hyosung Corporation and KEC International designed, constructed and tested a 400kV indoor GIS substation at Jigmeling. The substation was inaugurated in December 2017.

Power transmission from the Bhutanese hydropower project

Most of the electricity generated by the Mangdechhu hydropower project meets the energy requirements of Bhutan. The surplus electricity is exported to India.

The produced electricity is transmitted to the Jigmeling substation in Bhutan via two 80km-long 400kV double-circuit transmission lines. Electricity to the Indian grid is transmitted from Jigmeling to Salakati.

In April 2019, India and Bhutan signed a protocol, formalising the tariff at Rs2.4 / unit for 35 years. The tariff will be increased by 10% every five years until the loan is repaid and 5% thereafter.

Mangdechhu hydroelectric project contractors

India’s state-owned National Hydroelectric Power Corporation (NHPC) acted as a design and engineering consultant for the Mangdechhu hydropower plant.

Jaypee Group subsidiary Jaiprakash Associates won the contract for the construction of the dam, diversion tunnels, underground powerhouse, shafts and the intake structures for the Mangdechhu project.

Jaiprakash Associates subcontracted Bauer for the installation of seepage cut-off walls at cofferdams and related foundation engineering works, enabling the installation of the main dam.

BHEL won an Rs5,940m ($110m) contract to provide electromechanical equipment package for the project. The contract includes the manufacturing, supply, erection and commissioning of four Pelton turbines and generators, control system and other auxiliary equipment.

Alstom T&D India is the power transformer supplier for the project. The company supplied 13 units of 75MVA, 400kV generator transformers and an 80MVAR, 400kV shunt reactor as part of the Rs550m ($9m) contract.

Bhutan Power Corporation (BPC) built transmission lines from Mangdechhu plant to Jigmeling.

PES Engineers, Kalpataru Power, Gammon India, Marti India, Encardio-rite, Central Electricity Authority (CEA) and Water and Power Consultancy Services (WAPCOS) were also contracted for the project.