The Long Ridge energy generation project is a 485MW combined-cycle power plant developed in Hannibal town in Monroe County, Ohio, US.

The power plant is operated by Long Ridge Energy Generation (LREG), a subsidiary of US-based infrastructure company Fortress Transportation and Infrastructure Investors (FTII).

LREG developed the combined-cycle facility as a carbon-free, hydrogen-burning power plant to improve its energy efficiency and reduce its carbon footprint.

The power plant helps provide low-cost energy to Ohio. It is the first power plant of its kind in the US to generate electricity by burning a blend of hydrogen and gas in a combustion turbine.

The Long Ridge power plant began commercial operations in October 2021.

The project employed up to 500 workers during the peak phase of construction and generated up to 20 permanent operation and maintenance jobs upon completion.

Long Ridge power plant location and background

The Long Ridge power plant sits on 20 acres of the 1,600-acreage of the Long Ridge Energy Terminal, a multi-modal energy terminal in the Appalachian Basin.

The plant occupies the site of the former Ormet aluminium plant in Hannibal, which was shut down in 2013. The site is directly accessible from the Ohio Route 7 state highway.

FTII purchased the Long Ridge Energy Terminal assets in June 2017 through its subsidiary, Ohio River Partners Shareholder.

The Long Ridge energy generation project was approved by the Ohio Power Siting Board (OPSB) in July 2017. The final investment decision (FID) on the project was taken in February 2019, with construction works commencing in May 2019.

The Long Ridge power plant was originally planned as a gas-fired combined-cycle power plant, but the decision to convert it to run on carbon-free hydrogen was announced in October 2020.

LREG submitted a letter of notification to the OPSB in July 2021, seeking an amendment to the project’s approval certificate to authorise the use of up to 20% hydrogen in the combustion turbines’ hydrogen and natural gas fuel blend.

The power plant began blending hydrogen into its fuel mix in March 2022. Hydrogen was supplied from a nearby industrial facility, which produced it as a byproduct.

Long Ridge power plant make-up

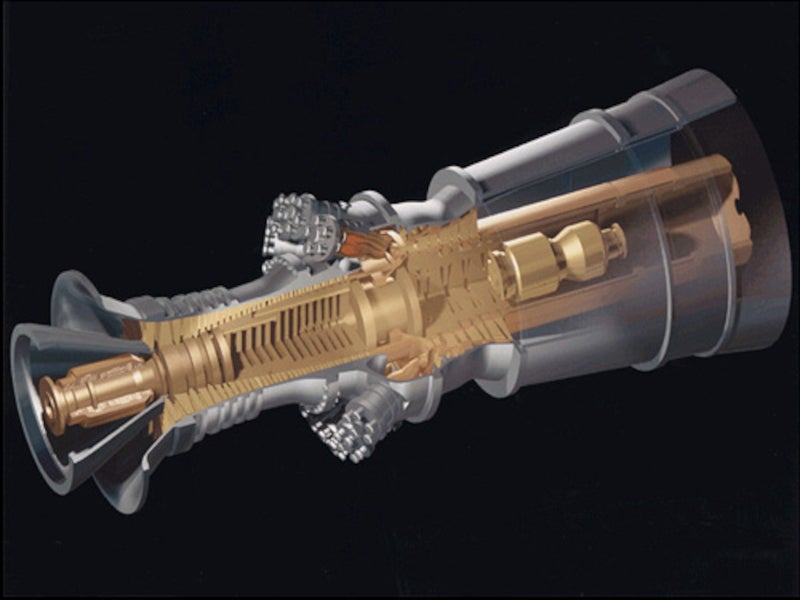

The Long Ridge power plant features a General Electric (GE) H-class gas turbine, a horizontal gas flow heat recovery steam generator and a GE D650 steam turbine.

A GE 7HA.02 combustion turbine, with a rated combined-cycle net output of 573MW, was installed. The turbine is designed for easy installation and boasts a combined-cycle efficiency exceeding 63%. Its modular configuration simplifies maintenance tasks while the dual-fuel system reduces water consumption and eliminates the need for recirculation.

GE’s 7HA gas turbines can combust up to 50% hydrogen and are continuously upgraded by the company to accommodate higher hydrogen fuel volumes (up to 100%), thereby reducing emissions through the decarbonisation of power generation.

GE has implemented its H2 Integrated Fuel Blending System at the power plant, enabling the initial use of a fuel mix that includes 5% hydrogen by volume, combined with natural gas. Future enhancements to the system are expected to increase the proportion of hydrogen used, subject to its availability and the economic landscape.

The developer is also investigating the on-site production of hydrogen and is assessing the viability of subterranean salt formations for large-scale hydrogen storage.

Financing for the Long Ridge energy generation project

LREG signed the first lien credit agreement in February 2019, with its two subsidiaries, Ohio Gasco and Ohio PP Holdco, for a $445m construction loan and a $154m letter of credit facility for the project’s construction.

Power transmission details

The electricity generated by the Long Ridge power plant is transmitted through the existing Kammer-Ormet 138kV transmission lines connecting the 138kV Ormet station.

A new 138kV Hannibal station, owned and operated by American Electric Power, was built at the Ormet station site. It is a nine-breaker switching station, connecting the Long Ridge project to the four existing 138kV transmission lines.

The Kammer-Ormet 138kV transmission lines were diverted to reach the new Hannibal station.

Contractors involved in the project

Kiewit Power Constructors, a division of US-based engineering and construction company Kiewit, secured an engineering, procurement and construction (EPC) contract for the project.

GE signed an agreement with FTII to provide power generation equipment for the project in February 2019.

Power generation service provider NAES was contracted to provide operations and maintenance (O&M) services for the power plant in February 2020.

Black and Veatch, a US-based EPC company, worked with Long Ridge to develop plans for the safe integration of hydrogen blending in the power plant’s gas turbine.

GE selected Flenco as the preferred supplier for the auxiliary systems required for this project.

Additionally, Axpo provided a long-term hedge for the electricity generated by the project, ensuring financial stability and risk management for its output.