The world’s largest PFBC (Pressurised Fluidised Bed Combustion) began commercial operations in July 2001. The 360MW plant at Karita, Japan, was commissioned in 2000, with ABB Stal supplying the gas turbine and Toshiba supplying the steam turbine.

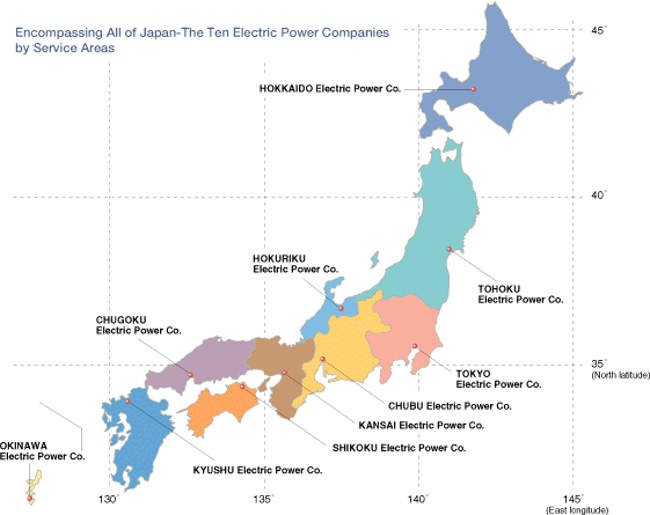

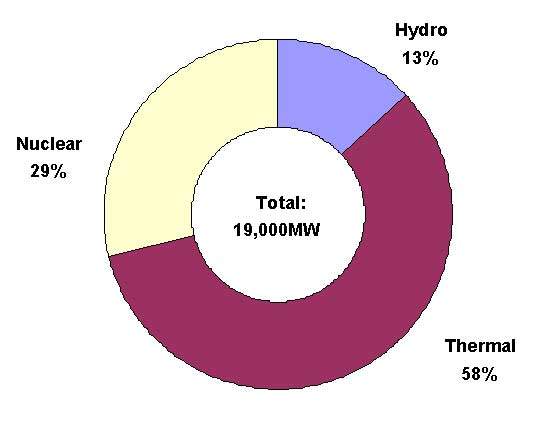

Kyushu Electric Power is one of the ten major vertically integrated regional supply utilities in Japan. The company has 17,500MW of installed capacity and is currently building what will be the largest PFBC system in the world. The PFBC combined steam / gas cycle offers efficient and pollution-free operation in a compact plant, compared with the conventional coal-fired thermal power generation.

In 1994, ABB supplied a PFBC plant for Wakamatsu in Japan; it had previously installed its P200 PFBC design in the USA, Sweden and Spain. The P800 design currently being constructed at Karita for Kyushu Electric Power has a nominal output of 360MW, which is four times that of the P200. The plant has been designed to burn low-sulphur coal. So that the coal can be sourced at the most competitive rates, the plant design is able to tolerate coals of varying quality.

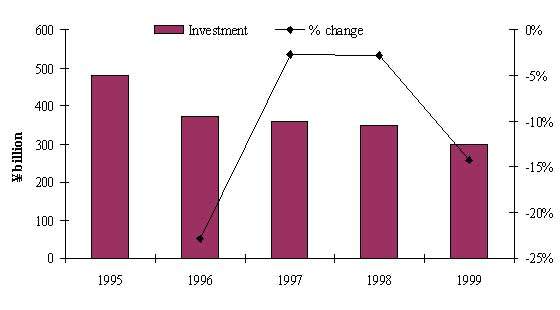

The PFBC pressure vessel was placed in position at the end of 1997. Installation of the gas and steam turbines and an auxiliary plant was carried out from mid-1998 onwards.

PFBC plant details

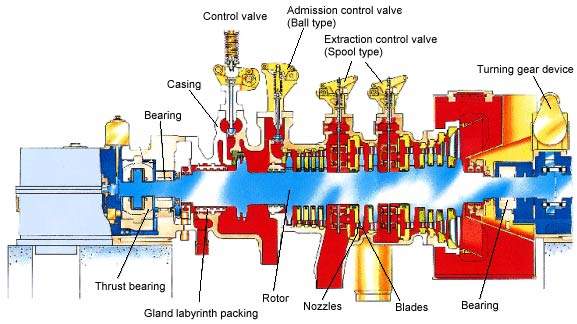

The plant was engineered and constructed by Ishikawajima Harima Heavy Industries (IHI) under licence from ABB Carbon, Sweden. IHI manufactured and erected the pressure vessel and PFBC system internals, fuel and ash handling equipment and the control system. ABB Stal provided the heavy-duty gas turbine that both creates the fluidised bed and provides air for combustion. Toshiba provided the steam turbine.

The pressure vessel for the P800 is three times larger than the vessel for the earlier P200 design. The output has been increased four times, chiefly by operating the pressurised system at 18bar rather than 12bar as in the earlier design. The pressure vessel was made at IHI in Yokohama. It was then shipped to the IHI plant at Aioi so that the internals could be installed.

Inside the pressure vessel, the fluidised bed enclosure is hexagonal in shape. It is divided into three equal sections. Above the bed are 12 pairs of cyclones, bed reinjection vessels and the steam generator pipework. The completed 3,600t PFBC vessel is 52m-high and has a diameter of 16m. It took Asia’s largest marine crane to lift it from the delivery barge onto the transport platform, on which it was rolled 600m to its final position on site.

Coal feed

The coal feed is crushed and screened to produce an optimum grain size. It is then mixed with crushed limestone and water to make a paste, which can be forced through fuel nozzles into the fluidised bed by using a piston pump.

The GT140P gas turbine supplied for this project was the largest ever made by ABB Stal. It is a two-shaft type with a rated output of 75MW. The turbine was specially designed to meet the exacting operation conditions in the PFBC application. It was extensively tested at the manufacturer’s works before delivery. To meet emission regulations the flue gas is passed through an electrostatic precipitator. A de-NOx system is fitted to the gas turbine outlet. It uses an ammonia selective catalyst technique.