The world’s first micro-scaled concentrated solar power (CSP) plant at the National Energy Laboratory of Hawaii Authority (NELHA) in the Kona desert was inaugurated in December 2009. It has an installed capacity of 2MW and costs approximately $20m. The official name of the project is ‘Holaniku at Keahole Point,’ which comes from the Hawaiian term for a location that has everything required for self-sufficiency.

The Micro CSP idea was conceived in 2006 and developed by Sopogy, a specialist in the development, design, manufacture and distribution of Micro CSP technology. The project was funded by Sopogy and local investors. Sopogy and its development partner Keahole Solar Power have a goal to bring 30MW of Micro CSP to the state by 2015, in an effort to give a boost to the Hawaii Clean Energy Initiative.

The plant is part of the initiative to reduce the state’s imported energy to 30% within 20 years, as it spends $5-7bn each year on oil imports. The plant will reduce the state’s oil import by 2,000 barrels a year and carbon emissions by 6,000t over 30 years.

The CSP plant supplies 500KW of electricity to the national grid, Hawaii Electric Light Company (HELCO). It can provide enough clean solar thermal power for more than 250 Hawaii homes.

Micro-scaled CSP thermal plant

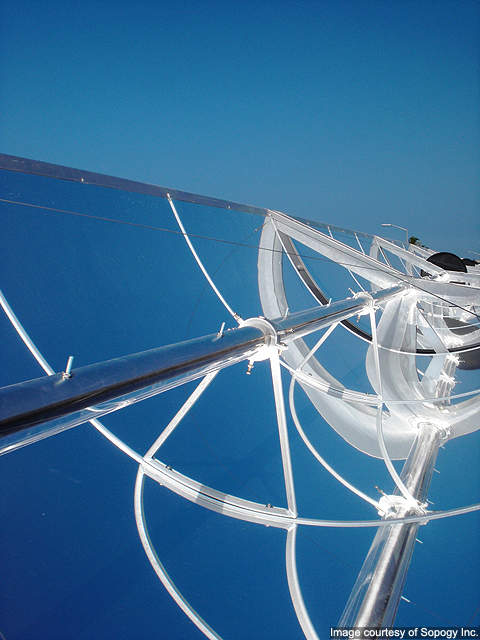

The plant spreads over 3.8 acres of Kona desert with 1,000 SopoNova 4.0 solar panels. Each panel is 3.7m long and weighs 68kg. It has a reflector surface of 5m². The solar panels are 20-40% more efficient than conventional photovoltaic modules and magnify solar heat by 60 times.

A glass tube runs parallel through the length of the solar panel. The glass tube is designed with one tube inside another with vacuum space between them to reduce heat transfer by conduction. These tubes are painted silver to reduce the heat loss caused by radiations.

The mirrors, optics and integrated sun tracker reflect the sunlight at different angles, producing temperatures as high as 392°F (200°C), which is directed on the glass pipes. Petrol-based thermal oil inside the glass pipes captures heat, which is transmitted to the two 4,000gal water tanks. These tanks keep the oil / water hot to enable the plant to work even during a cloudy day or throughout the night.

An array of insulated pipes, valves and pumps carry the hot water from the tanks into the two 50KW ElectraTherm ‘Green Machines,’ which convert the heat into clean electrical power.

The ElectraTherm Green Machine operates at a higher reliability and with a faster return on investment compared with traditional turbines. The machine uses a closed-loop Organic Rankine Cycle (ORC) to create pressure by boiling chemical working fluids into vapour. The vapour expands and moves in a one-way closed pipe system causing pressure to turn the twin screw expander, which drives a generator to produce clean electricity. The gas is cooled and condensed back into liquid in the condenser.

The Micro CSP plant also has a storage buffer that stores the energy for production during cloudy periods and also shifts energy produced during the day to the evening.

Contractors

The sun reflectors were delivered by German aluminium coating specialist Alanod Aluminium-Veredlung, while the green machines were supplied by ElectraTherm Inc.

Hawaiian power market

Hawaii derives 90% of its energy from oil imports. It is an isolated island and has no conventional resources such as coal, natural gas or oil.

Petroleum is the major source of energy production in Hawaii. It produces 84.7% of electricity through petroleum, 8.2% through biomass and the remaining 7.1% electricity comes from coal, hydroelectricity, wind and geothermal resources.

Hawaii has an installed capacity of 2,437MW and generates 876,000MW/h. The state has now taken an initiative to reduce its dependence on oil imports and to produce 70% clean energy by 2030. The CSP technology is a major step in achieving this ambitious target.

Hawaii has solar resources to produce 4,500-6,000W/h per square metre using photovoltaic systems and 3,500-4,500W/h per square metre using CSP.

Hawaii ranks 16th in the US for energy efficiency as it spends more than $9m annually on energy efficiency. Its per capita residential electricity use is 2,489KW/h per year, which is 45% less than the national average.