The concept of building Hong Kong’s first offshore wind farm was formulated in May 2005, following the release of the first sustainable development strategy for the country. The strategy set an objective of supplying 1–2% of the Hong Kong Special Administrative Region’s (HKSAR) total power through renewable sources by 2012.

The proposed Hong Kong offshore wind farm would generate approximately 1% of HKSAR’s total power generation, with an output of 200MW. Renewable energy generated at the wind farm would power nearly 80,000 households. The wind farm is expected to offset 343,000–383,000 tons of carbon dioxide, 45–60t of sulphur dioxide, 394–440 tons of nitrogen oxide and 14–16t of particulate material each year.

Execution of the project is subject to the acquisition of an environmental permit, installation of an offshore mast, the collection of wind and wave data for at least one year and other project and regulatory processes. If approved, the project will be built by electricity investor-operator CLP in partnership with Wind Prospects, an independent renewable energy developer.

Wind farm site

The wind farm will be developed in an area of 16km² approximately 10km east of Clearwater Bay Peninsula and 5km east of East Ninepin Island in the south-eastern waters of HKSAR. Due to unavailability of significant usable land in HKSAR, an offshore site was more feasible for large-scale renewable energy development. The site has a water depth of approximately 30m.

Proposed installation

The project will comprise either 67 x 3MW or 40 x 5MW wind turbines. Built specifically for an offshore environment, each turbine will consist of 45m-long blades and 80m-high hubs. If the larger (5m) and lesser number of turbines are installed, the blades would measure 60m and the hubs 90m. Turbines will be spaced at approximately five to ten times the blade length.

Each turbine installation would take on an average one to two days, completing the process in about 17 vessel movements. To install the turbines, barge or jack-up vessels will be used. Each component will be prefabricated in factories before being transported to the site for installation. Turbines will be installed after the foundation installation is complete.

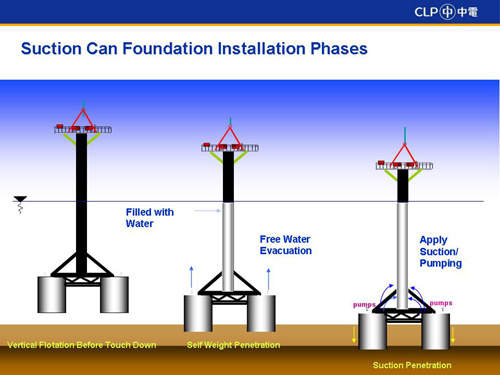

For the foundation, the wind farm is considering suction caisson technology. To be introduced in Hong Kong for the first time, the suction caisson would be fitted with a four-legged jacket that would serve as the substructure. The design would avoid the need for dredging or marine piling, therefore minimising environmental impact. The foundation was tested at the proposed site in May 2008 and was found to create minimal disturbance while being installed into the sea bed.

The wind turbines will be connected to the offshore substation via 33kV electrical collection cables. Two 132kV transmission cables will be used to export power from the transformer platform to the wind farm. They will be installed at a depth of 3–5m.

The collection cables and majority of the transmission cables will be installed through the jetting method. The rock armour method along with jetting will be used for 3km of transmission cables that require additional protection. The rock armour method involves dredging at the maximum rate of 6,300m3 a day, not exceeding 135,000m3 of dredged materials.

The project will be completed over a two-year period. During the construction period, approximately 120 heavy lift vessel movements and 3,360 support vessel movements will be made. The work on the site will be carried out at specific isolated areas instead of occurring continuously over the entire site area.

Environmental impact

BMT Asia Pacific, a subsidiary of BMT Group, conducted an environment impact assessment (EIA) and marine navigation safety risk assessment of the project. According to the assessment the project will have no significant environmental impact.

Largely due to the choice of site, the potential for impact in terms of waste, water quality, benthic ecology, pelagic ecology, avifauna ecology, fisheries, heritage and landscape and visual has been offset. Within Hong Kong waters, the 16km² project site is a relatively low productive area. The adoption of suction caisson technology has also greatly reduced any potential impact.

Maintenance

The project will require minimal maintenance and supervision over its lifetime. Through a computer system installed in every turbine, all the operations will be controlled and monitored by the operators. On notification of any problem, the required maintenance will be provided by 20 engineers on site. At any given point of time, between one and three maintenance vessels will be made available near the site location.