The Fadhili gas-fired combined heat and power plant is a co-generation power plant in the Eastern Providence of the Kingdom near Fadhili (FGP), which is located 50km away from Jubail Industrial City in Saudi Arabia. Located adjacent to the Fadhili gas processing plant, the co-generation power plant is designed for an installed capacity of 1,520MW.

Saudi Aramco Power Holding Company and Saudi Electricity Company (SEC) hold 30% stake each in the project company, while ENGIE, which was contracted to develop the plant on build, own, operate, and transfer (BOOT) basis for a period of 20 years, holds 40% equity. The companies own the project through a special purpose vehicle known as Fadhili Plant Cogeneration Company (FPCC).

The construction for the project began in 2016 and the first two gas turbines began commercial operations in February 2019.

The electricity generated by the plant will be equivalent to the consumption of 1.4 million people. The plant can produce 1,447t an hour of steam and 768.8t an hour of feed water, which is supplied to Saudi Aramco.

The project is expected to create employment opportunities for more than 4,500 local people.

Fadhili power plant make-up

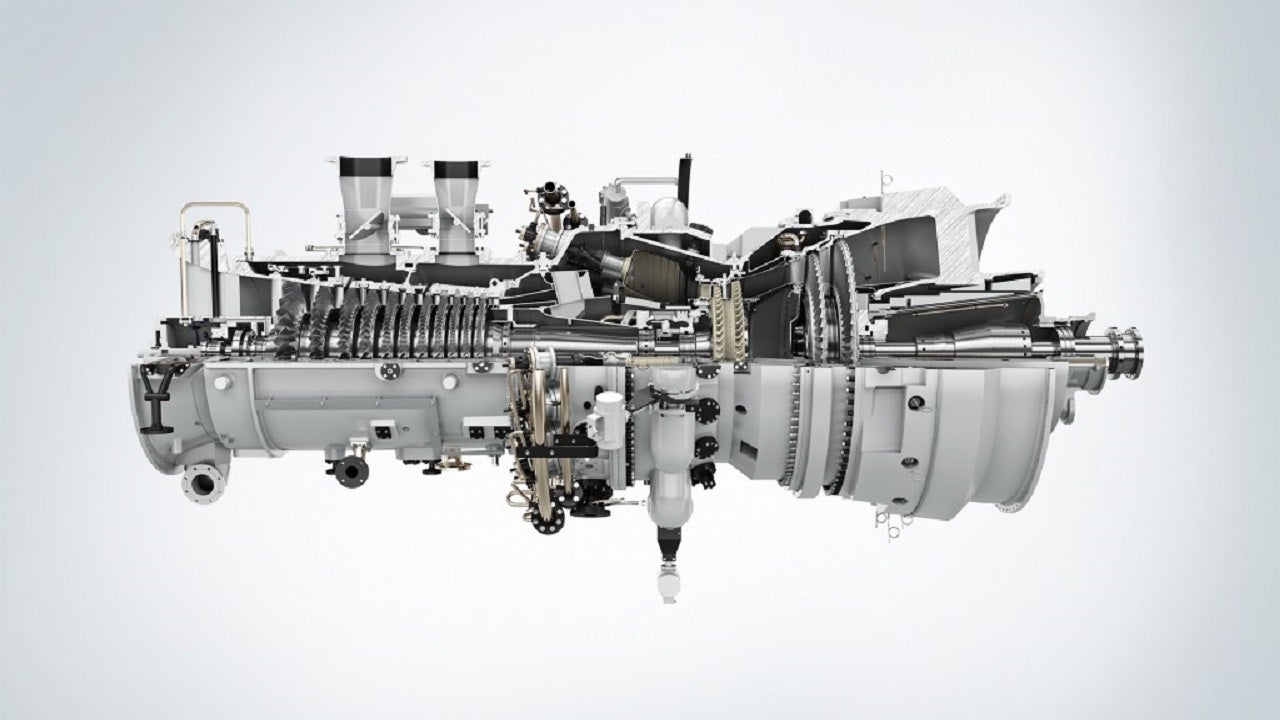

The Fadhili combined-cycle power plant is equipped with five SGT6-5000F gas turbines, in addition to SGen6-1000A generators and SPPA-T3000 control system.

The natural gas required for the plant’s operations is supplied from the adjacent Fadhili gas processing plant.

The co-generation power plant supplies 400MW of electricity and steam to Fadhili gas processing plant, while the remaining 1,100MW is supplied to SEC for distribution to 1.1 million households across Saudi Arabia.

Contractors involved with the Fadhili co-generation power plant

Doosan Heavy Industries & Construction was awarded an engineering, procurement, and construction (EPC) contract worth approximately $900m for the Fadhili power project in December 2016. The contract included services, ranging from design to equipment manufacturing, installation, and pilot operation at the plant.

ENGIE and Doosan Heavy Industries & Construction were engaged for the EPC works, including the construction of a 380kV substation, which was transferred to SEC in 2018 for ownership, operation, and maintenance.

Siemens was awarded a $400m contract to supply five F-class gas turbines for the plant. The turbines were manufactured at the Siemens Dammam Energy Hub (SDEH) facility located in the Middle East. The contract also included supplying five generators and a control system, and advanced power diagnostics services.

Siemens, in association with ENGIE’s affiliate Kahrabel FZE, also offered maintenance services for the turbines for a period of 16 years.

Portland Bolt provided anchor bolts and embedded plates for the project.

Financing for the combined heat and power plant

The total investment for the plant construction was estimated at $1.2bn as part of the SR50bn ($13.3bn) Fadhili gas extraction plant.

The financial closure for the construction of the power plant was achieved in January 2017. The project was partially financed through $950mn of non-recourse project finance debt by six banks, including Export-Import Bank of Korea (Kexim), Islamic Development Bank, Sumitomo Mitsui Banking Corporation (SMBC), KfW Ipex-Bank, MUFG, and National Commercial Bank.

Fadhili gas processing plant details

The Fadhili gas processing plant is expected to process up to 2.5 billion standard cubic feet a day (SCFD) of non-associated gas, including two billion SCFD of gas from Hasbah offshore gas field and 500 million SCFD of gas from Khursaniyah onshore gas field.

The plant was estimated to enhance the supply of natural gas to Saudi Arabia to up to 17bn SCFD by 2020, creating growth opportunities for steel, aluminium, and downstream value-added industries in the country.

The plant has the capacity to produce 1.5bn SCFD of sales gas and 4,000 metric tonnes of sulphur a day through tail gas treatment. It can supply 470 million SCFD of gas to the Fadhili co-generation power plant.

The Fadhili gas processing facility had been receiving steam from the gas-fired combined heat and power plant since November 2018. It achieved 98% completion as of 2020.