Emissions-reduction company 2Co Energy is developing a 650MW integrated gasification combined-cycle (IGCC) coal-fired power plant and a carbon capture and storage (CCS) demonstration project in Stainforth, Doncaster, South Yorkshire.

The project was stalled when its former developer Powerfuel Power became bankrupt in December 2010. The group was acquired by 2Co in May 2011 and it renamed the project, from the Hatfield CCS project, to Don Valley Power Project (DVPP). The total estimated investment in the development is £5bn (€6bn).

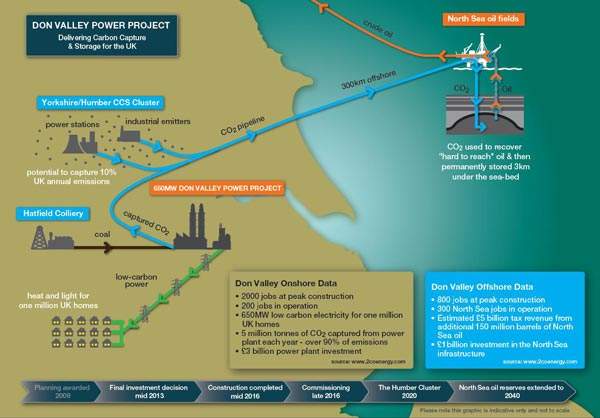

The DVPP will generate sufficient heat and electricity for about one million houses. The CCS unit is expected to capture about five million tons of CO2 per annum. It is equivalent to 90% of the total carbon emissions from the plant.

Finances behind the Don Valley Power Project (DVPP)

The DVPP consists of both offshore and onshore works. The onshore project, comprising of the IGCC power plant and the CCS, is estimated to cost £3bn. The power plant is planned to sit in proximity to the Hatfield Colliery, previously owned by Powerfuel Mining.

About £2bn will be spent on developing a CO2 transportation pipeline network and associated underground injection infrastructure. The project will receive funding of £150m (€180m) allocated under the European Energy Programme for Recovery (EEPR) in 2009. It is also competing for the EU’s NER300 funding competition by European Investment Bank (EIB).

IGCC coal-fired power plant and a carbon capture and storage details

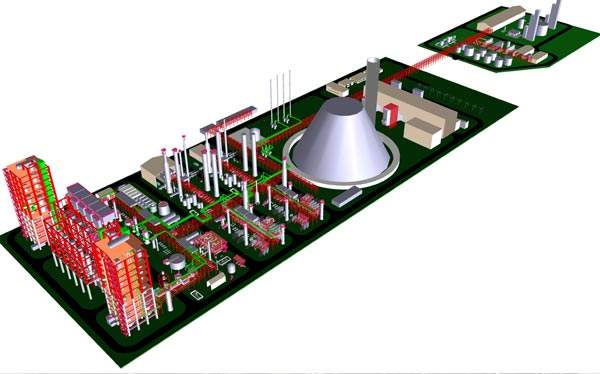

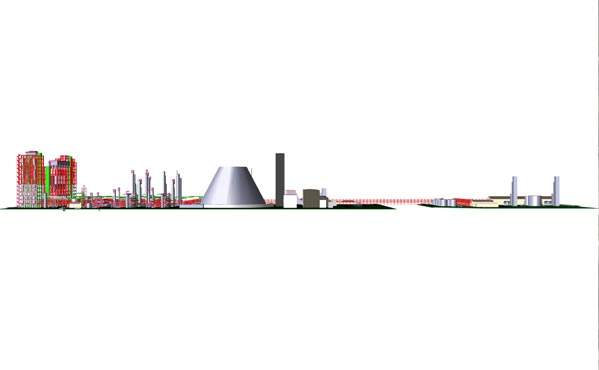

The power plant and CCS will include: shift reactors, gasification and refrigeration units, a sulphur recovery unit, CO2 compressors for exportation, a cooling tower, heat recovery steam generator (HRSG) and HRSG stacks, a turbine hall, a water generation and storage plant, plus administrative and control buildings.

The power plant will use hydrogen rich water vapour gas for power generation. GE has been chosen to supply the turbines, Shell for gasifiers and UOP for the acid gas removal system. About 90% of CO2 from the coal gasification unit is expected to be captured from the output flue emissions.

In October 2010, AFC Energy and B9 Coal signed a letter of intent to install fuel cell technology at the power plant. AFC Energy’s alkaline fuel cells are expected to increase the efficiency of the plant by 60%, using hydrogen from syngas.

Construction of 2Co Energy’s South Yorkshire-based power facility

Planning permission for the power plant was received in February 2009. Final investment decision will be taken in mid-2013 paving the way for construction. It is expected to be built by mid-2016 and commissioned by late 2016.

Foster Wheeler was selected to provide project management consultancy services, in January 2012. The company will assist 2Co Power in preparation of the engineering, procurement and construction (EPC) contract.

Jacobs provided the front end engineering and design for the DVPP. It was completed in 2009. The power plant project is expected to generate about 2,000 construction jobs at its peak. It will employ about 200 staff for operations. About 800 jobs will be created during construction of the offshore part of the DVPP.

Yorkshire / Humberside CCS technology hub project

The UK is planning to invest about £1bn towards reducing the GHG emissions by 34% by 2020 and by 80% by 2050.

A CCS technology hub will be built to capture CO2 from the fossil fuel fired power plants in the region. Called the Yorkshire / Humber CCS Cluster, it is expected to be ready by 2020. The CCS hub is expected to capture about 10% of the annual UK CO2 emissions.

National Grid Carbon, a subsidiary of the National Grid, is acting as the project partner. The company will be responsible for identifying suitable locations for carbon storage and developing the CO2 transportation pipeline. Nabarro and Linklaters are the CCS project advisors.

Talisman Energy and 2Co are working on the enhanced oil recovery (EOR) and CO2 storage in the North Sea under the DVPP. The EOR will double the output from the reserves, which otherwise could go unrecovered. The captured CO2 is expected to extend the life of North Sea reserves until 2040. The gas will then be stored permanently into geological formations three kilometres below the seabed.