The Crescent Dunes Solar Energy Project is a concentrating solar power (CSP) plant built near Tonopah in Nye County, Nevada, US. The 110MW plant is the first commercial-grade solar power plant in the US to be fully integrated with energy storage technology. It is also the world’s largest solar power facility with storage. The estimated cost of the project is $1bn.

The project entered its commissioning phase in February 2014 following completion of the construction phase. It is expected to generate about half a million megawatt-hours annually of emission-free electricity, enough to meet the needs of approximately 75,000 households. It will eliminate 290,000 metric tonnes of CO₂ emissions annually.

The project was executed by an American power production company SolarReserve through its affiliate company, Tonopah Solar Energy.

Crescent Dunes solar power plant financing

In September 2011, Tonopah Solar Energy received a $737m loan guarantee from the US Department of Energy (DOE) to finance the construction of the Crescent Dunes solar power plant.

The remaining project cost was financed by SolarReserve, the Spanish engineering and construction company ACS Cobra and the Spanish banking firm Santander.

Development and construction of the CSP plant

The Crescent Dunes solar energy project was approved by the US Department of Interior in December 2010.

The project began in August 2011 with limited construction activities. An official ground breaking ceremony was held in September 2011. The project attained a major construction milestone in February 2012, when erection of the central receiver solar power tower was completed. Standing at 540ft, it is the world’s tallest solar power tower.

The construction was completed by early 2014 and commercial operations began in September 2015.

Crescent Dunes power plant design

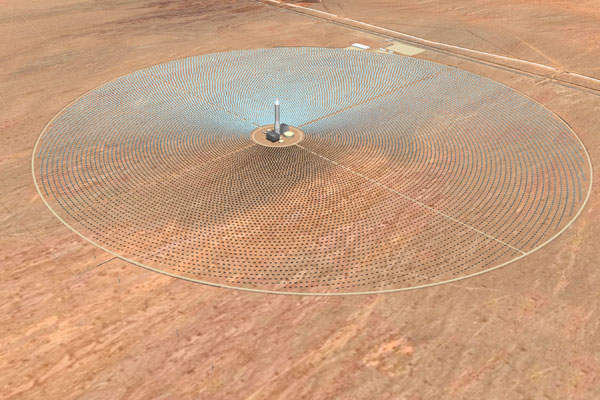

The Crescent Dunes CSP is built on about 1,600 acres (647.5ha) of public land administered by the US Bureau of Land Management. It is designed for an operational life of 30 years.

The two main components of the facility include a large circular field consisting of 17,170 heliostat mirrors and a central receiving tower to which the solar radiation reflected by the heliostat mirrors is focused. The plant uses a conventional steam turbine to produce electricity.

Thermal storage tanks on the tower store hot and cold liquid salt heat transfer fluid. A hybrid cooling system comprising an air-cooled condenser is also installed.

Other components of the project include a water treatment system, evaporation ponds, buildings, a parking area and an access road.

Crescent Dunes CSP technology

The Tonopah solar power plant uses an advanced molten salt storage system, which is capable of storing up to ten hours of solar energy.

The CSP technology makes use of heliostat mirrors, which reflect solar radiation to heat molten salts passing through a series of tubes installed on the central receiver tower. The molten salt is then transferred to a large insulated tank for storage.

From the insulated tank, the hot molten salt is passed through a series of heat exchangers to produce highly pressurised, superheated steam. The steam is used to run a conventional turbine to generate electricity.

Surplus thermal energy is stored in the molten salt and can be utilised to produce additional power for up to ten hours.

Distribution of solar power from the Crescent Dunes project

In December 2009, Las Vegas-based NV Energy, an investor-owned holding company providing energy services and products in northern and southern Nevada, signed a 25-year power purchase agreement (PPA) with SolarReserve for the plant’s output.

The majority of the power generated by the Tonopah plant is delivered to the Anaconda 230kV Substation, located about 13km north of the site, by means of a proposed high-voltage transmission line.

Contractors and suppliers

Nevada-based Cobra Thermosolar Plants, a subsidiary of Spanish civil and engineering construction ACS Cobra, is the general contractor for the project.

Pratt & Whitney Rocketdyne, a subsidiary of United Technologies, received an order in October 2011 to supply hardware associated with the plant’s molten salt thermal energy system.