TransAlta expanded its Centralia Big Hanaford power plant site with a 248MW combined-cycle gas turbine (CCGT) unit. The site has two coal-fired units, and operates as a merchant power plant. Acquired in 2000, Centralia is TransAlta Corporation’s only coal-fired power plant in the US. It generates enough electricity each year to supply a city about the size of Seattle. Net generation has been 10,478,711MWh.

TransAlta has also invested in emission control technology to cut sulphur dioxide emissions by 90%, as well as nitrogen oxide emissions. The Centralia power plant is equipped with scrubbers, gas turbines, a steam turbine and a heat recovery steam generator (HRSG). As well as the power generation units, Centralia also has a coal mine, which can fuel the coal-powered power units.

Centralia plant

In April 2010, the Department of Ecology of the Washington state and TransAlta entered a memorandum of understanding (MoU) to decrease the greenhouse gas emissions from the plant. The MoU also aims to supply replacement capacity by 2025. The MoU was signed following the Governor Gregoire’s 2009 Executive Order on Climate Change. The order directed the Washington state to work with TransAlta to reduce emissions from the plant.

Construction of the gas-fired power plant commenced in April 2001 and began operation in August 2002.

The construction of a new power plant in the area was welcome as the region’s generators were only just able to meet winter-time demand.

Generating units

The existing coal-fired plant consists of two generating units with a total capacity of 1,340MW. The units were built in the early-1970s.

The new gas-fired plant added 248MW of electricity to the Pacific Northwest energy market and is on the same site as TransAlta’s coal-fired power plant. The cost of the new gas-fired unit was $215m.

Coal-fired units

Each of the coal-fired units at Centralia is more than 200ft-high. Powered coal is fed through 64 nozzles to feed them.

The temperature can be as high as 3,000°C. This generates the pressurised steam to drive two massive steam turbines (over 100ft-long, and weighing 600t each).

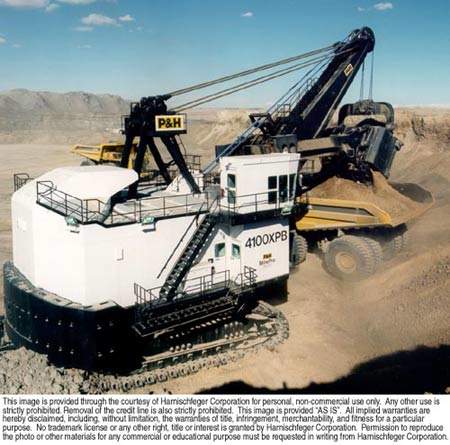

The units use two P&H 4100XPB coal shovels to transport the coal to the generators. These employ Optima Plus dipper and load 270t/245m haulers supplied by P&H Mining Equipment.

The Centralia plant’s coal-fired units use 70% local coal, mainly supplied by the nearby coal mine.

Environmental improvements and emission reduction

When TransAlta bought the plant, it agreed to uphold the recommendations of a collaborative decision-making process among key stakeholders in the area. In keeping with those recommendations, TransAlta installed $200 million US scrubbers on the plant, making it among the cleanest coal-fired power plants in North America. The scrubbing technology was supplied by ABB Environmental Systems.

To date, TransAlta has invested more than $300m in pollution control and technologies to reduce emissions at the plant.

Contractors for the power plant

TransAlta is a joint venture. The partners are: PacifiCorp (47.5%), Avista Energy (15%), Seattle City Light (8%), Tacoma Power (8%), Snohomish PUD (8%), Puget Sound Energy (7%), Portland General Electric (2.5%) and Grays Harbor County PUD (4%). Portland General Electric sold its 2.5% stake to Avista Energy in 2000 before the plant was entirely sold to TransAlta.

Stone & Webster, in a consortium with ABB Environmental Systems, was awarded the engineering, procurement and construction contract from PacifiCorp to design and build a flue gas desulfurisation system for the Centralia power plant.