The Selective Catalytic Reduction (SCR) system at the 1300MW Brandon Shores power station has been upgraded to improve NOx reduction efficiency. The upgrade extends the SCR regeneration cycles to bring a 250 ton yearly reduction in NOx emissions, and savings of US$200,000 in NOx credits.

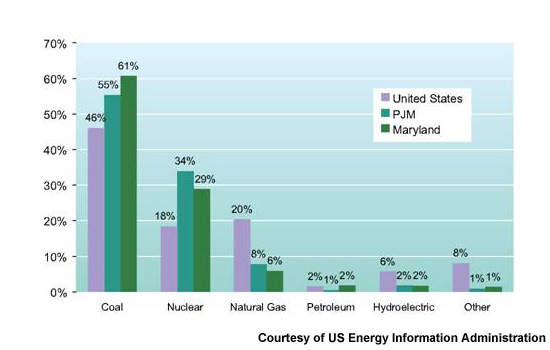

Brandon Shores occupies a 152-hectare site in Anne Arundel County, Maryland, USA. It has two coal-fired steam boilers. Unit 1 came on line in 1984 and unit 2 in 1991, each producing 690MW gross. The plant also uses overfire air and low NOx burners, as well as a hot side electrostatic precipitator before the SCR. The power station uses 0.7% sulphur coal to avoid the need for scrubbers.

Brandon Shores uses 250 tons of coal an hour

Brandon Shores is owned by Constellation Power Source (formerly BGE). It uses around 250 tons of coal per hour, and typically between 5000 and 6000 tons per day. The coal is brought in by barges carrying up to 7000 tons, shared with Wagner power station. There is normally a 300,000 ton storage pile at Brandon Shores, giving a 30-day backup.

At Bandon Shores, steam from the boilers initially passes through the turbines at very high pressure. To improve efficiencies, the steam is reheated to 538°C and piped through the turbines again before being condensed back into water. The station uses closed cycle cooling with mechanical draft towers, and two 213m high stacks. It produces 600,000 tons of fly ash per year, with most being used as structural fill (used, for example, in Brandon Woods Commercial Park).

Reducing NOx emissions at Brandon Shores

An SCR system was added in 1999 at a cost of US$100m, reducing NOx emissions by 90%. It operates during the annual ozone season between May and October, at a cost of around 4% plant efficiency.

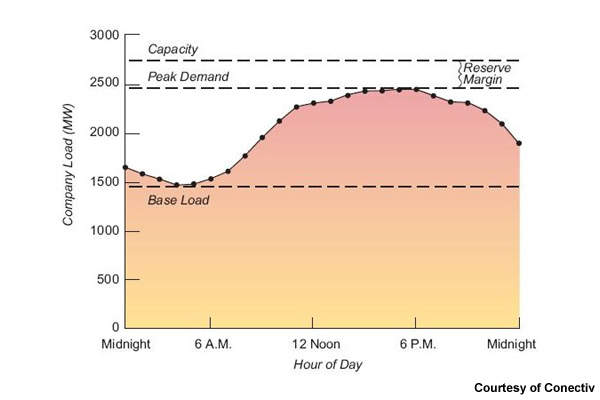

The SCR system works by injecting ammonia into the flue gas to neutralise NOx. The flue gas entering the SCR must be greater than 307°C for full 90% efficiency. If the flue gas falls below this the ammonia flow rate drops, reducing the NOx reduction efficiency. If the flue gas falls below 290°C, SCR operation stops completely.

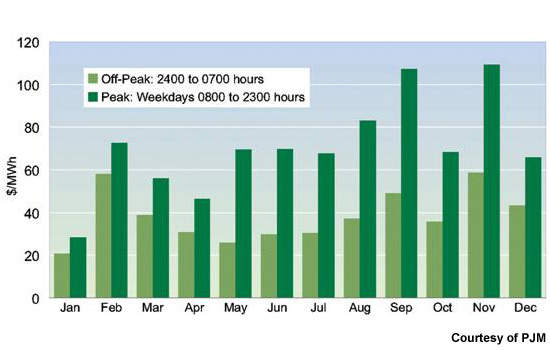

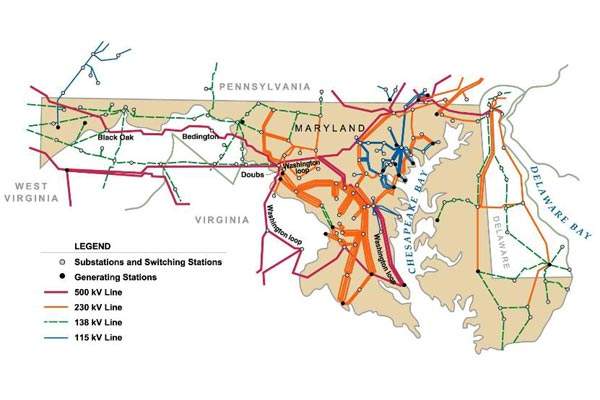

Because Brandon Shores participates in the PJM regulatory interconnection market, it must follow fluctuating load demand closely. Flue gas temperature is greatly affected by plant load, and the flue gas temperature frequently used to drop below 307°C and sometimes even below 290°C. The original SCR control systems were then unable to optimise the flue gas temperature, and struggled to maintain the minimum SCR inlet temperature. Constellation therefore needed to control the SCR inlet temperature more tightly.

Ovation improves SCR optimisation

Emerson revised the original OEM design using its Ovation expert control system and SmartProcess SCR optimisation. The Ovation system controls the plant’s boiler, burner management, data acquisition and flue gas desulphurisation processes. It provides tighter control of the economiser remix temperature across the entire load range by revising control of the economiser bypass and outlet dampers. This gives more consistent control of the SCR inlet and remix temperatures.

SmartProcess SCR optimisation uses fuzzy logic to monitor the system and predict current flue gas composition and optimum ammonia use. SmartProcess also automatically calculates the best bias settings for oxygen, fans and dampers to provide tighter control of the inlet temperature.

Improved SCR efficiency reduces NOx levels

Since its installation in 2006, the improvement in SCR efficiency has reduced NOx generation, NOx credit purchases and ammonia use, and has extended SCR regeneration cycles.

The Brandon Shores SCR previously operated below its targeted 90% NOx reduction efficiency rate for around 190 hours during the ozone season, emitting roughly 650 tons of NOx. After the upgrade, this was reduced to 70 hours and 400 tons. At a rate of US$800 per ton, that has saved Constellation US$200,000 in NOx credits.