The Belarusian Nuclear Power Plant (NPP) is being constructed approximately 18km away from Ostrovets, Grodno Oblast. The 2,400MW NPP, consisting of two 1,200MW units, will be the first of its kind in Belarus.

The project was conceptualised in 2007 with the site being selected in 2011. Design works started in 2012, the first concrete was poured in November 2013 and above-ground works started in September 2014. The first unit was scheduled for commissioning in November 2018, followed by the second unit in July 2020.

The project is being overseen by the state enterprise Directorate for Nuclear Power Plant Construction, who will also be the operator, under the Ministry of Energy.

The overall investment for the development of the power plant is estimated to be $11bn. The governments of Belarus and Russia will jointly finance 90% of the cost.

Belarusian NPP project benefits

The 2,400MW Baltic nuclear power plant, comprising two units of 1,200MW each, is being constructed in the northeast of the Kaliningrad Region, within the Neman municipal area of Russia.

The project will address the power demand in Belarus, which has scarce domestic fuel resources. It aims to diversify energy resources, replace the import of natural fossil fuels (five million tonnes of fuel equivalent a year), reduce electric power production costs and increase the country’s capacity to export electric power.

The project will also generate approximately 8,000 jobs during the peak construction period as well as 1,000 new permanent jobs when it starts operations.

Belarusian nuclear power plant location

The project site covers an area of approximately 44,994ha. It was selected out of 54 potential locations evaluated. The nearest bordering state to the project site is the Republic of Lithuania, which is 23km away.

Plant reactors

The Belarusian NPP will integrate two third-generation VVER-1200 type reactors (AES-2006), which are a Russian version of the Pressurised Water Reactor (PWR). The NPP is designed to accommodate two additional reactors by 2025. Similar reactors are also being used at the Leningradskaya NPP-2 in Russia and Hanhikivi-1 NPP in Finland.

Each of the reactors will have a service life of 50 years and net efficiency of 33.9%. The energy consumption for their internal needs will not exceed 7.48% of the nominal power.

The new reactor system will feature added safety elements including a passive heat removal system, a system for dumping and cleaning the reactor shell environment, double-protective containment and a molten fuel trap in the event of an unpredictable accident.

Construction of the nuclear power plant

As of July 2015, approximately 68,400t of reinforcement bars had been installed, 456,300m of concrete poured and the construction works had crossed the 20% mark.

The NPP project further involved the upgrade of the national power grid to accommodate the additional power and construction of an urban settlement for the workers involved in the project, including a training centre.

The lifting and transportation of heavy construction materials was performed by deploying a Liebherr 11350 hoisting crane with a lifting capacity of 1,350t.

Contractors involved

The general contractor for the project is Atomstroyexport, a subsidiary of Rosatom. The design documentation was developed by Atomproekt, while the Joint Institute for Power & Nuclear Research, Sosny of the National Academy of Sciences of Belarus is providing scientific support for the project.

Atomenergomash, a subsidiary of Rosatom, has been contracted to supply the two reactors and the molten core catcher for the two units. It further subcontracted AEM-technologies to manufacture the reactor vessels, core catcher, upper blocks, reactor shafts, reflection shields, block of protective pipes and other related equipment.

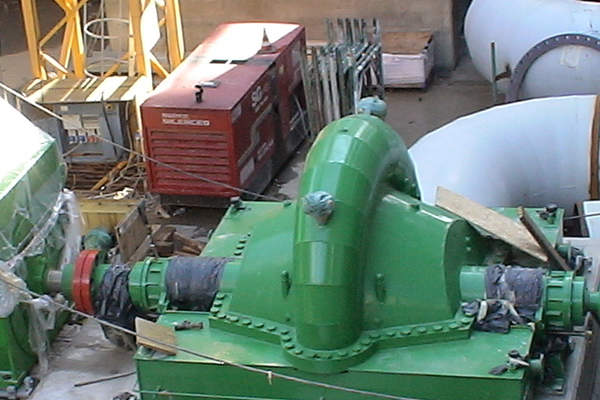

OJSC Power Machines has been contracted to supply two complete turbine sets, including 1,200MW high-speed steam turbines, capacitors, equipment for the turbine auxiliary systems and two 1,200MW turbogenerators.

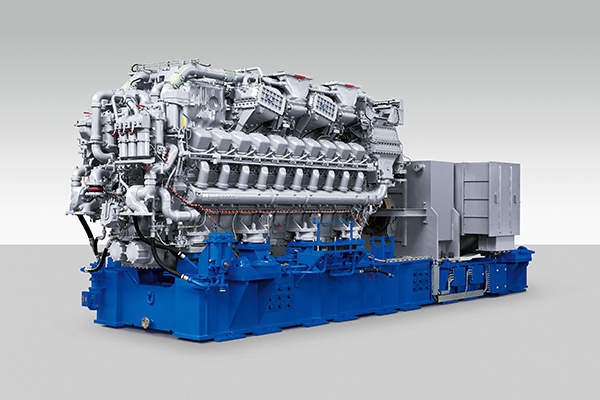

MTU Friedrichshafen, a subsidiary of Rolls Royce, is supplying ten high-speed 20V 956 TB34 emergency diesel gensets (EDGs) for the two reactors, whereas KPA Unicon is supplying its Unicon SF-40 steam boilers for the power plant.

Ganz Engineering and Energy Production Machinery will supply its BPC-1800 type pumps for the plant’s water circulation system.

OMZ Group’s Izhorskiye Zavody is manufacturing the pressure compensation valves and main circulation lines, while its subsidiary OMZ-Special Steels will supply a batch of semi-finished metallurgical products for the reactor vessels, under a subcontract from AEM-technologies.

OMZ-Special Steels will supply the rotor blanks for the project in collaboration with JSC Power Machines. MSA, a subsidiary of Rimera, will supply 100 butterfly valves for the project.

The main automatisation contractor for the project is AGAT Control Systems, a subsidiary of Geoinformation Control Systems.