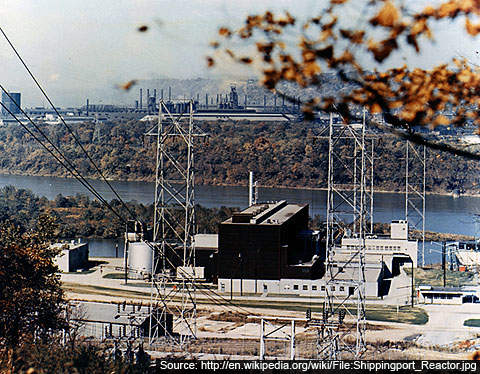

Beaver Valley Nuclear Power Station is a two-unit nuclear power plant located near Shippingport, 25 miles north-west of Pittsburgh, in western Pennsylvania, US. The plant features two pressurised water reactors (PWR), Unit 1 with 911MW and Unit 2 with 868MW. The first reactor, Unit 1, was serviced in July 1976, followed by second reactor, Unit 2, in August 1987. The plant produces 1,815MW of electricity, sufficient to power 1.4 million homes in addition to reducing up to 12t of carbon dioxide every year.

Unit 1 is owned by Pennsylvania Power Company (65%) and Ohio Edison (35%). Unit 2 is owned by Ohio Edison, Toledo Edison, Cleveland Electric Illuminating and Pennsylvania Power in the proportion of 41.9%, 24.5%, 19.9% and 13.7%, respectively.

The plant is operated by FirstEnergy Nuclear Operating Company (FENOC), a subsidiary of FirstEnergy Corp. FENOC is also the holding company of Ohio Edison, Toledo Edison and Cleveland Electric Illuminating.

In July 2009, the US Nuclear Regulatory Commission (NRC) renewed the licence period of Units 1 and 2 until 2036 and 2047, respectively. The original licence was set to expire in 2016 for Unit 1, followed by Unit 2 in 2027.

Beaver Valley project details

Beaver Nuclear plant was built to meet the increasing electricity demand in the north-east of the US. Frequent blackouts in this region were considered as evidence to increase electricity generation.

The plant was originally constructed and operated by Duquesne Light in an emergency planning zone of Pennsylvania, Ohio and West Virginia. The Emergency preparedness (EP) programme in Pennsylvania includes on-site emergency response readiness and coordination with local emergency response organisations and off-site states.

Duquesne Light was taken over by FirstEnergy in 1999. Since then, FirstEnergy has invested $500m to upgrade the plant in order to ensure safe and continued operations. FirstEnergy began upgrading the plant in 2000 under the Full Potential Programme (FPP), which was executed in phases over a period of eight years. The FPP mainly focused on engineering, economic and safety initiatives to upgrade the plant’s systems and procedures.

Beaver Valley Nuclear Power Plant

The two units initially had a capacity of 810MW each, supplying 2,660MWt of nuclear steam in total. In July 2006, the plant’s capacity was increased by 9.4% to 2,900MWt as a result of the approval given by the NRC in coordination with the FPP.

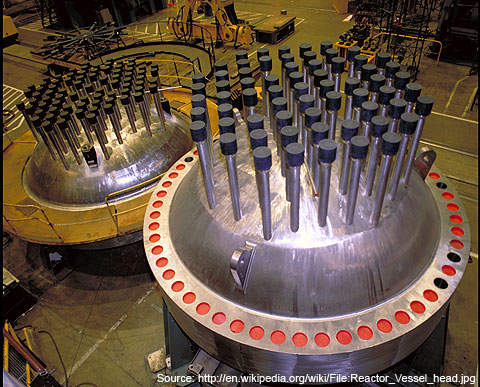

Existing safety analysis was re-visited and the latest analytical techniques, such as radiological alternative source term (AST), were incorporated to update the estimates for the loss of coolant accident (LOCA). To maintain an additional safety margin, Unit 1 steam generator-Model 51 was replaced with the latest technology generator. In addition, the reactor vessel closure of Unit 1 was also replaced with a simplified head package to reduce the outage duration and worker’s exposure during inspections. Unit 2 was replaced with high-pressure turbines to increase electricity production.

The containment design was modified and upgraded from a sub-atmospheric to atmospheric design. This reduced the overall size of the containment and reduced the potential for post-accident radiological releases. It also increased personnel safety and optimised equipment monitoring by the staff.

On 17 April 2009, the production capacity of Unit 1 was down by 14%. It was operating at 92% capacity on 16 April 2009 and was shut down for a month-long refuelling and maintenance outage on 20 April 2009. Unit 2 was also shut down on 12 October 2009 for the same purpose. It began producing electricity at 22% capacity on 27 November 2009.

Technology

The reactor in the PWR generates heat, which is carried to the steam generator through the primary coolant loop. Steam in the steam-line is directed towards the turbine, which turns the generator to produce electricity. The steam turns into vapour in the secondary loop placed inside the steam generator. The unused steam is cooled in the condenser where it is turned into water, which is pumped back to the steam generator through an array of pumps.

The fuel assemblies in the reactor are cooled by the force-circulated water. Emergency cooling water is supplied by the pumps powered through the use of diesel generators.

All other safety systems, such as containment cooling, are also powered by diesel generators.

Contracts

The plant was designed and engineered by Stone & Webster. The steam generators and nuclear reactors were supplied by Westinghouse Electric.

The US power market

The US is the largest producer and consumer of electricity, with a global share of more than 25%, followed by China. As of January 2010, the US produced and consumed 3,992 billion KWh of electricity. With such a high rate of consumption, the country is now banking on renewable energy sources.

According to the consulting firm Black & Veatch, around 50% of the electricity consumed in the US will be produced by gas combustion turbines or combined-cycle units by 2034. Nuclear power production will grow, due to the jump in renewable energy, from 54,000MW to more than 165,000MW in 2034.

The US has not built any new nuclear plants in the recent past but is on an upgrading spree. It has added 5,640MW of new capacity by uprating existing nuclear plants. About 500MW worth of up-rates are pending the NRC’s approval, which is expected to rise to 1,713MW by 2013. The average capacity factor of the nuclear plants has also increased from 56% in 1990 to 92% in 2007.