Andasol power station in southern Spain is Europe’s first parabolic trough solarpower plant. The site of the facility is on the plateau Guadix in the province of Granada and is comprised of three power plants: Andasol 1, 2 and 3. The three plants constitute the largest solarpower station in the world. The entire cost of the project was estimated to be around €900m.

The three units have a net electricity output of 150GWh per annum from each plant.The third plant was commissioned in September 2011. Andasol 3 is expected to produce 165 million kilowatt hours of electricity every year. When compared to an advanced coal-fired plant, the new plant is expected to reduce annual carbon emissions by up to 150,000t.

The project achieved a new milestone in September 2010 when the installation of the 50MW units and 85t generator was completed after facing logistical barriers. Turbines had to be transported from Denmark, England, Germany and Italy via ships and heavy-goodsvehicles. The generator had to be shipped from England.

Andasol will supply environmentally friendly solarpower to approximately 450,000 residents in Spain. It will also contribute to Spain’s peak electricity demand during summer.

Andasol solarpower station project details

The plants Andasol 1 and Andasol 2 are owned by Central Termosolar Uno, a company owned by Cobra Sistemas y Redes (75%) and Solar Millennium Verwaltungs (25%). Cobra Sistemas y Redes is a subsidiary of the ACS / Cobra Group. The Andasol 1 and Andasol 2 plants have been developed by the project partners ACS / Cobra Group and Solar Millennium.

Marquesado Solar SL (MSS) is the owner and developer of the third unit, Andasol 3. The shareholders of MSS include Solanda GmbH (26%), Stadtwerke München (48.9%) and RWE Innogy & RheinEnergie (25.1%). Solanda is a joint venture between Solar Millennium and MAN Ferrostaal AG.

Engineering services, including the planning, design, construction supervision and control of the plant, were provided by Flagsol GmbH, a subsidiary of Solar Millennium.

Solarpower plant details

The Andasol power station site is located at an elevation of 1,090m to 1,100m above sea level, over an area of 1.53 million square metres.

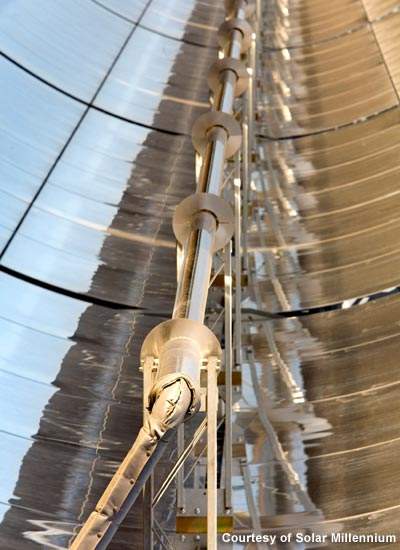

Each unit of the power station comprises 90km of absorption pipes and curved mirrors, which together form the collectors. The plants each have 312 collector rows and can generate 50MW. A collector includes 28 mirrors and three absorption pipes.

Andasol’s plants also use dry-cooling systems to reduce water consumption. The plants comprise solar fields, thermal storage systems, heat exchangers, steam turbines, generators and condensers.

The rating of each turbine of the power plant is 50MW. Each turbine weighs 160t. The turbines for the first two power plants were built by Siemens, while those for the third plant were built by MAN Turbo in Oberhausen in England. Each plant has 22,500 absorption pipes manufactured by Schott Solar and Solel Solar Systems.

The mirrors are made of silver-coated and curved white glass. Those installed in Andasol 1 and 2 were manufactured and supplied by Flabeg Group. The mirrors that are installed in the third plant were manufactured and supplied by Rioglass Solar SA.

The plant’s thermal reservoir acts as a back-up in case of rain or after sunset during the night. It is capable of operating the turbines for 7.5h at full-load.

The heat reservoirs integrated in the power plants each have two tanks. The tanks containing liquid salt are 14m high and have a diameter of 36m. They store up to 30,000t of storage medium. The molten salts will be heated to 390°C by the solar field and pumped to the tanks. The stored energy is released during nights or cloudy weather to convert into electricity. A full storage can operate the turbine for eight hours at full capacity.

Andasol power station construction

The construction of Andasol 1 began in July 2006 and the plant became operational in March 2009. The construction of the second power plant began in February 2007 and started its test run in mid-2009. The third plant, Andasol 3, is pre-registered. Its construction began in August 2008 and was inaugurated in September 2011.

The three power plants are practically identical in construction. The work included the construction of foundations to fix the steel support rods, which are in turn affixed with mirrors and absorption pipes. Steel pylons are used to anchor the metal support structures.

The 150m-long collector chains were set with the hydraulic drives, with a precision of up to a tenth of a millimetre. The 312 collector rows are fixed in north-south axis and follow the sun from east to west along a single axis.

Andasol 1 was connected to Spain’s power grid in December 2008. Andasol 2 was connected to the grid in mid-2009, while the third station began commercial operations in the last quarter of 2011.

Solarpower technology

Andasol generates power by converting solar radiation into heat energy. The trough-shaped mirrors of the plant project the radiations onto a pipe at the centre of the collector.

The fluid in the pipe is heated by the radiations and generates steam in the power block through a heat exchanger.

The steam produced is used to drive the turbine, as in conventional power plants. The turbines drive the generators that produce electricity.

The direct steam production and heating of molten salt in absorber tubes increases the efficiency and reduces the cost of power production.

The parabolic trough power plants provide a facility to store efficient heat energy. The thermal storage system aids in generating power even after sunset to meet demand.

The orientation of the collectors is carried out automatically through the control room of the power station.

Andasol project finance

Andasol 1 received funds from banks in May 2006. The corresponding finance contracts were signed during the same year.

Solar Millennium funded Andasol 2 in cooperation with several other banks. The proceeds that provided collateral for financing Andasol 2 were placed by Solar Millennium in February 2008.

The third Andasol station is financed by Solar Millennium, Stadtwerke München, RWE Innogy, RheinEnergie and MAN Ferrostaal.

Environmentally friendly solarpower

The solarpower station will cut the carbon emissions in the region by 450,000t per annum compared with conventional coal-fired power plants.