The 112MW Albatros offshore wind farm is located 95km north of Borkum island in the exclusive economic zone of the German North Sea. It was developed as an expansion of the 497MW Hohe See wind farm, located nearby.

Albatros wind project is jointly owned by German utility EnBW (50.1%), Canadian energy infrastructure company Enbridge (25.4%) and Canada Pension Plan (CPP) Investments (24.5%).

Enbridge was responsible for the development of both the Hohe See and Albatros wind farms, which came online in October 2019 and January 2020, respectively. EnBW handles the operations and maintenance of both wind farms.

With a combined installed capacity of 609MW, Hohe See and Albatros wind farms can generate up to 2.5 billion kilowatt hours of energy, catering to the power requirements of 710,000 households in Munich, Germany, and offsetting roughly 1.9 million tonnes (Mt) of carbon emissions a year.

Construction of the $305m Albatros wind power project began in 2018, and the last turbine was installed in September 2019. The 112MW wind farm was connected to the grid in January 2020.

Ownership history

Enbridge previously held a 49.89% interest in both the Hohe See and Albatros wind projects, which it acquired from EnBW in 2017.

CPP Investments acquired 49% of Enbridge’s combined interests in the two projects in 2018. It issued approximately €510.6m ($557.2m) in green bonds to refinance its minority stakes in the two German offshore wind projects in February 2020. Insurance group Talanx funded €321m ($350.3m) of the green bonds.

Albatros offshore wind farm make-up

The wind farm is located in an area of approximately 11km², in water depths of up to 40m. The location has wind speeds of up to 10.1m/s.

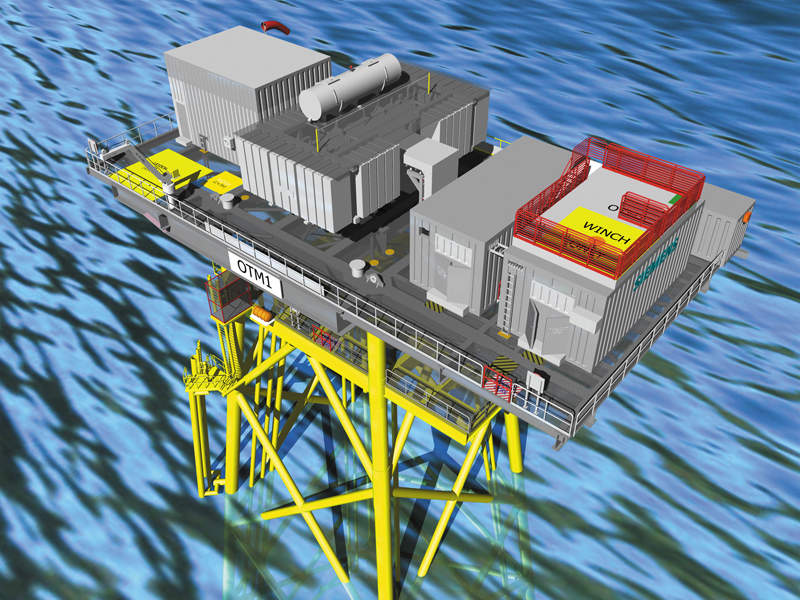

Albatros is installed with 16 Siemens Gamesa SWT-7.0-154 wind turbines, with a hub height of 105m and rotor diameter of 154m. The 7MW direct-drive turbines are installed on monopile foundations. The wind farm also includes an offshore transformer module (OTM®) with a transmission capacity of 116MW.

Turbine details

The Siemens SWT-7.0-154 turbine is a low-weight wind turbine developed to meet the International Electrotechnical Commission’s (IEC) class IB standards. The blade length of the turbines is 75m and the swept area is 18,600m².

The turbine can withstand harsh offshore weather conditions and deliver 10% more energy than its predecessor, the SWT-6.0-154. They are programmed to automatically shut down if the wind speeds exceed 10.1m/s, which improves grid stability.

The turbine design also includes robust and proven IntegralBlades® technology and reliable safety systems. The turbines are equipped with direct drive technology, which reduces wear and tear, and a permanent magnet generator that further improves efficiency.

Albatros wind farm transmission details

Using the OTM, the offshore wind farm is grid-connected through the Borwin Beta HVDC converter platform, located 25km away from the project site, to the power grid.

The OTM weighs approximately 1,000t and features an ultra-compact design, which reduces installation costs as well as service and maintenance costs. It uses the same foundations as that of the turbines, which results in further cost savings.

Contractors involved

Siemens Gamesa Renewable Energy was awarded the engineering, procurement and construction contract for the Albatros wind farm. The contractual scope included the supply and installation of the turbines and OTM. It also included service and maintenance of the turbines for a period of five years.

Siemens subcontracted Heerema Fabrication Group for procurement and construction of the OTM.

Manor Renewable Energy was contracted to supply the full temporary power package of generators, personnel and vessels for the wind turbine installation.

Siemens also subcontracted GeoSea, a subsidiary of DEME Group, for the fabrication and installation of turbine foundations.

A joint venture of Sif Group and Smulders was subcontracted by Geosea for the construction of the monopiles. Sif produced the monopiles, while Smulders provided the transition pieces.

Sif Group subcontracted Euskalforging to fabricate and supply 16 flanges for the foundations of the turbines.

Palfinger Marine was subcontracted by Siemens to deliver 16 fixed-boom cranes, while VBMS was contracted by EnBW to supply inter-array cabling.

Offshore installation vessels Innovation and Sea Installer were used to install the turbine foundations, while offshore supply ship Pacific Osprey was used to transport the foundations to the project site. Other installation vessels used for the project included Brave Tern and Blue Tern.