The Lillgrund wind farm is a 110MW offshore project in Öresund, near Malmö, Sweden. Built with an investment of Skr1.8bn (€18m), the wind farm came online in June 2008. It is operated by the utility company Vattenfall.

Constructed by Siemens Power Generation, the wind farm generates about 330GW/h per year, enough to power about 60,000 homes.

Plant make-up

The wind farm uses 48 SWT-2.3-93 turbines, a variable speed version of Siemens’ standard SWT-2.3-82, with a larger rotor and better economy at sites with moderate wind speeds.

The offshore sub-station is equipped with 120MVA transformer that boosts voltage from 33kV to 138kV. It also houses medium-voltage switchgear and an auxiliary power transformer on the platform.

Technology

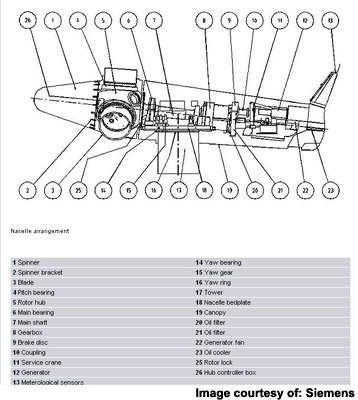

The SWT-2.3-93 rotor has a three-blade cantilevered construction, mounted upwind of the tower. The power output is controlled by pitch regulation. The blades are made of fiberglass reinforced epoxy and are manufactured by Siemens in a single operation, using its IntegralBlade process. There are no glue joints between spars and shells, no weak points and no easy access for water or lightning.

The blades are mounted on pitch bearings and can be feathered 80 degrees for shutdown. Each blade has its own independent fail-safe pitching mechanism capable of feathering the blade under any operating condition, and allowing fine-tuning to maximise power output.

The gearbox is a custom-built three-stage planetary-helical design, mounted on the nacelle with flexible rubber bushings. The gearbox is fitted with a fail-safe mechanical brake at the high-speed shaft.

The generator rotor construction and stator windings have high efficiency at partial loads. The generator is fitted with a separate thermostat-controlled ventilation arrangement, and by ensuring efficient cooling can be operated at temperatures well below the normal level of the standard insulation class for long winding insulation lifetime.

The SWT-2.3-93 turbine is mounted on a tapered tubular steel tower. The tower has internal ascent and direct access to the yaw system and nacelle. The turbine controller is a microprocessor-based industrial controller; similar to the type used in other Siemens wind turbines.

The controller is complete with switchgear and protection devices. It is self-diagnosing and has a keyboard and display for easy readout of status and for adjustment of settings.

The turbine operates automatically, self-starting when the wind reaches an average speed of about 3m/s–5m/s. The output increases approximately linearly with wind speed until the wind reaches 13m/s–14m/s. At that point the power is regulated at rated power. If the average wind speed exceeds the maximum operational limit of 25m/s the turbine is shut down by feathering of the blades. When the wind drops back below the restart speed the safety systems reset automatically.

The turbine safety system has several redundant levels, including an independent pitch system for each of the blades. As a result the turbine can shut down safely from any operating condition. The WebWPS SCADA system offers long-distance control and a variety of status views and useful reports from a standard internet web browser. The SWT-2.3-93 turbine uses the NetConverter system with ride-through capability for all normal faults.

Several offshore Scandanavian parks

In 1991, Siemens installed the first offshore wind farm in Vindeby, Denmark. It also erected the 165MW Nysted offshore wind farm in the Baltic Sea, in 2003. Siemens also constructed an offshore contract for 25 of its 3.6MW wind turbines for the Burbo Banks offshore wind farm in Liverpool Bay off the British west coast in October 2007.

In 2008, Siemens started building the world’s largest offshore wind farm off the east coast of Great Britain. The Lynn and Inner Dowsing project has 54 SWT-3.6-107 wind turbines, with a maximum capacity of 180MW. It is being operated by British gas provider Centrica.

Development

ABB won the contract worth $16m (about €12m) from Siemens to supply over 33km of power cables for Lillgrund. Reliable XLPE cable interconnections carry offshore wind power to the mainland.

The single core AC cable and armored three core AC cable has integrated optical fiber, and is supplied by ABB’s high voltage cable and accessories production facilities in Sweden. Project scope included underground and submarine XLPE (cross-linked polyethylene) insulated cables, cable laying and cable installation.

ABB supplied and installed the six-kilometer-long, 145kV underground cables, and 27km-long 145kV and 36kV submarine cables to interconnect the turbines and transmit the power to the Swedish mainland.

Bladt Industries delivered the offshore transformer platform.