Canadian battery recycling company RecycLiCo has announced it will enter into a joint venture with Taiwanese chemical company Zenith Chemical to construct a $25m battery recycling plant in Taiwan.

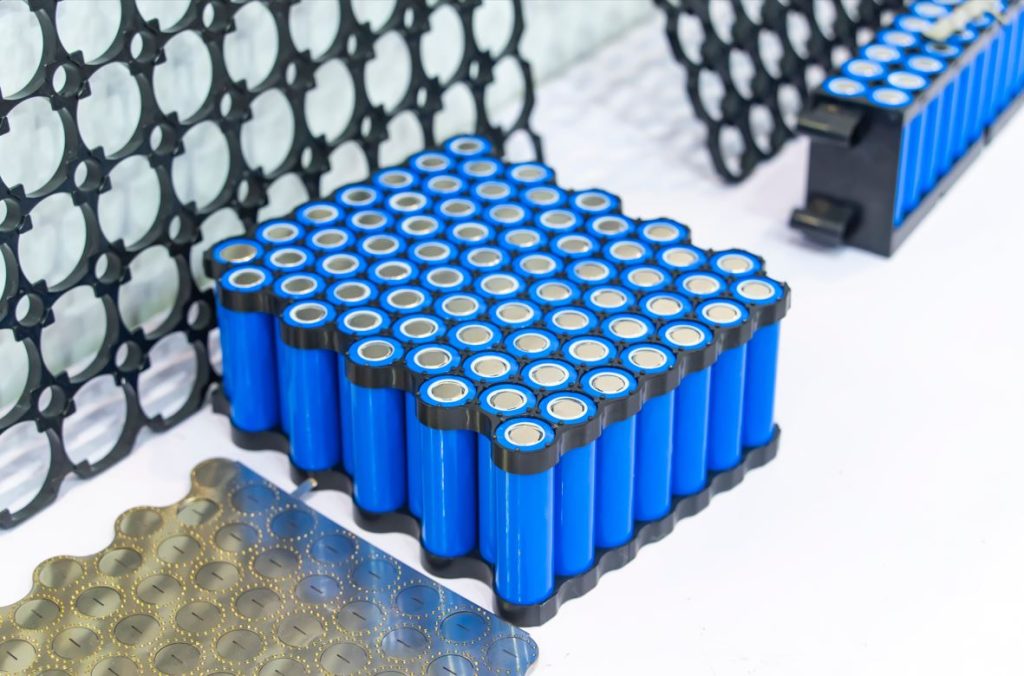

The 2,000 tonnes (t) per year plant will recycle lithium-ion (Li-ion) batteries into parts such as Li-ion cathode material and component chemicals such as lithium carbonate.

Zenith will pay 50% of the $25m in cash, while RecycLiCo will contribute 40% of its stake in cash, with the other 10% accounting for the license of its technology.

RecycLiCo chairman Paul Hildebrand said: “Zenith is an ideal partner for our first joint venture on several levels. They have deep technical expertise in chemical processing, and established infrastructure, which will enable us to move swiftly and efficiently toward production.”

The technology’s patent has already been licensed in seven countries, with Taiwan being the eighth. The technology has a promising recovery rate of up to 99% of critical minerals like lithium, nickel, copper and manganese. Its closed-loop hydrometallurgical process includes multiple stages of leaching and precipitation with the company’s patented leaching solution.

The closed loop enables the direct integration of the resultant chemicals into new battery materials on site. The process also consumes 62% less CO₂ than other hydrometallurgical processes.

As a result of the partnership, a share swap will also take place. Zenith will receive four million RecycLiCo shares and warrants to purchase a further six million. RecycLiCo will, in exchange, obtain royalties on net product sales. This marks the latest shift from companies towards the recycling and recovery of Li-ion batteries, spurred on by the rise in electric vehicle ownership. In April, Glencore, FCC and Iberdrola announced they would collaborate on a battery recycling plant of their own. At the time, it was reported that in Spain alone, 35,000t of batteries would be recycled annually by 2035.