Solar power is one of the world’s fastest growing energy technologies. A decade ago, there was only 20GW of installed capacity globally; today, there is over 600GW. As adoption continues apace, so does the race to make the most efficient solar cell.

On average a commercial solar panel converts 17-20% of the light energy hitting it into electricity – a significant increase from the 12% of ten years ago. But with better efficiency, solar technology could play a much greater role in mitigating climate change, improving the economics, in particular, for rooftop installations.

In recent years, several companies, such as Oxford PV, ICS, and Insolight, have made significant progress developing new technologies that improve solar efficiency – signalling a potential future shift away from the market leading wafer-thin silicon solar panels.

Reaching New Limits

The majority of solar cells today are made from wafer-thin slices of silicon crystals, most of which are produced in China and Taiwan. The technology was originally developed in the 1950s and has seen a steep fall in price over time.

This technology, however, has a theoretical maximum efficiency of 30% because it is made with only one material, known as the Shockley-Queisser limit. When combining different materials, researchers have demonstrated that it is possible to achieve efficiencies of up to 47%.

According to Dr Christian Jardine, senior lecturer in energy at Oxford University’s Environmental Change Institute and co-founder and technical director at Joju Solar, multi-material panels could theoretically reach 95% efficiency by deploying technologies such as quantum dots, semiconductor particles operating at the nanoscale. However, this has yet to be demonstrated.

“The ultimate thermodynamic efficiency limit, which can be achieved by a variety of techniques, basically involves stacking different types of solar panels on top of each other,” he explains.

Perovskite layers set global records

Achieving greater efficiency will mean more electricity can be generated with the lowest possible material input, making solar panels more sustainable overall.

One of the leading solar module innovators, which has won $140m in funding from firms such as Equinor and Legal & General Capital, is UK based Oxford PV. The company claims to have developed the worlds’ most efficient solar panels, and hopes they will be in production by the end of the year. The panels are coated with a thin layer of a crystal material called perovskite and have a theoretical efficiency limit of 43% because the crystal can absorb more parts of the solar spectrum than traditional silicon. In 2018, Oxford PV demonstrated a world record by reaching 27.3% efficiency.

Dr Chris Case, chief technology officer at Oxford PV, has said that the company is continuing to push its technology, with a roadmap that extends beyond 30% efficiency.

“The solar cells we are developing are not only efficient but also stable. Similar devices from our research and development facility have passed at least 2000 hours of damp heat reliability testing, in line with IEC 61215 protocol,” he added.

Another company, Polish startup firm Saule Technologies, is also developing perovskite-based solar cells. The company has recently completed a trial project using the ultra-thin solar cells on construction and development firm Skansa’s Warsaw office.

An advantage of perovskite is that it is a relatively cheap material. However, while perovskite is emerging as a leading contender for commercially viable next generation higher efficiency solar cells, Jardine says its durability is as yet unproven.

“There was a question over its longevity as a material in practical applications, there was a thinking it would be necessary to refit the solar panels every 10 years, because the material will degrade,” he explains.

“However, the approach they’re taking now is to put a layer of perovskite on top of a conventional cell, which is hoped will improve the lifetime of the perovskite, or at last the efficiency of the solar cell, for 10 years and then have normal efficiency thereafter.”

Other technologies

Oxford PV and Saule Technologies aren’t the only competitors in the solar efficiency race. Finnish technology company ICS has developed a similar film solution that enhances the amount of light led into solar cells. According to the company, it can increase the performance of solar cells by 5%-10%.

“We have found a way to capture and very precisely redirect light beams”, explains Kari Rinko, CTO at ICS.

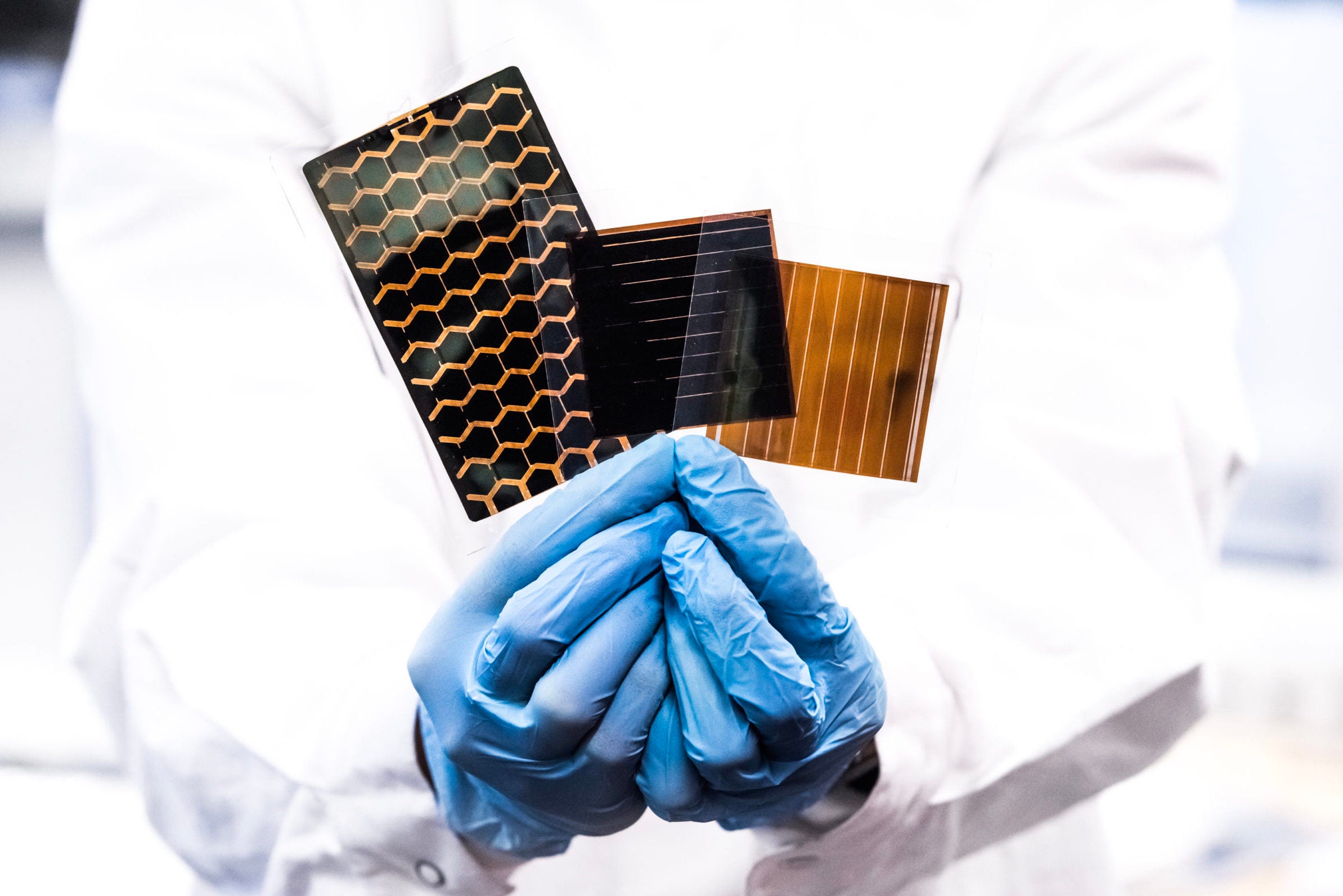

Called Solar Energy Optic (SEO) film, the technology is based on embedded cavity optics, with practical implementation that is not exposed to external influences and contamination. The ultra-thin film is produced by a cost-efficient roll-to-roll process, which the company says makes it scalable and ready for industrial adoption on a global scale.

“The SEO film is as effective as if the optics would be mounted on the surface of the solar module,” explains Rinko in a press statement.

He adds that it is more effective than any previously introduced and tested light capturing methodology.

The SEO solution has been tested by independent third parties like the Fraunhofer ISE , which confirmed the boost in efficiency rates.

Swiss startup Insolight has improved solar panel efficiency using a different method. It concentrates light 200x by embedding a grid of hexagonal lenses in a solar panel’s protective glass. According to the company, the technology allows 30% efficiency for sun-to-electricity conversion (300Wp/m2) – while mainstream modules achieve 18% on average. The Universidad Politécnica de Madrid’s measured the company’s technology as having an efficiency of 29%.

Improving the efficiency of solar cells has obvious benefits, but the most important is decreasing the amount of space and material needed to make higher levels of energy. This is why such improvements will mostly be beneficial for the residential and building space, rather than the large-commercial solar farm market, says Jardin.

“If investing in solar panels as a commercial generator, space is rarely a problem, therefore standard efficiency modules will give you the biggest return on investment. For buildings, however, where space is constrained, it makes much more economical sense to opt for high efficiency modules,” he explains.

Future forecasts

As the industry waits with bated breath to see which company emerges with the most commercial multi-material solar cell to rival the dominant silicon cell, the market is holding up against a tide of supply chain disruption due to Covid-19 and changing policy, such as the end of feed-in-tariffs implemented in the UK in April last year.

IHS Markit forecasts 105GW of new global solar installations in 2020, a 16% year-on-year decline from 2019 but still robust given the global economic outlook. It states that after the major short-term disruption from Covid-19, installation growth will resume from 2021 to continue the growth trajectory that solar PV has seen in the last decade.

“Solar power is now just cheap enough that it doesn’t need any policy support and I think the market is operating better without constant waves of government intervention,” says Jardin.

“High efficiency modules are proven to be important as people want to run their electric cars on solar and are concerned about climate change. Solar power can provide a chunky step change in carbon emissions,” he adds.