A new joint project from the UK and Japan, named ‘LongOps, will look to make decommissioning faster at the Tokyo Electric Power Company’s (TEPCO) Fukushima Daiichi reactors in Japan and the UK’s Sellafield nuclear site. Around £12m has been funnelled into the four-year research scheme, and it forms the latest part of the UK government’s £450m investment into robotics and autonomous systems since 2014.

The funding, which will also explore robotic applications in fusion research, will come equally from UK Research and Innovation, the UK’s Nuclear Decommissioning Authority, and TEPCO. Leading the project will be the UK Atomic Energy Agency’s (UKAEA) Remote Applications in Challenging Environments (RACE) facility.

Scarlett Evans (SE): Can you tell me about this project – how far along are you in developing these robotic arms?

Rob Buckingham (RB): LongOps is a four-year research and training collaboration between the UK and Japan on robotic operations in nuclear scenarios, including fusion energy and decommissioning.

It will help to unlock fusion as an almost limitless source of clean energy, as well as cleaning up nuclear sites with care for people and the environment.

The programme will carry out research and development to improve these operations through the use of innovative technology and software.

A major focus of the LongOps programme will be development of innovative ‘digital twin’ technologies, to help de-risk these challenging operations by improving efficiency, accuracy, and safety. Digital twins give us models that pair the virtual and physical worlds. This allows highly detailed analysis of data, and the forecasting of potential maintenance and operational issues.

We are right at the start of the project. The LongOps agreement was announced in January 2021 and we are about to place the first contract for robotic arms. When these are delivered, the research and operator training programmes will begin in earnest.

SE: What does it mean for the future of nuclear decommissioning?

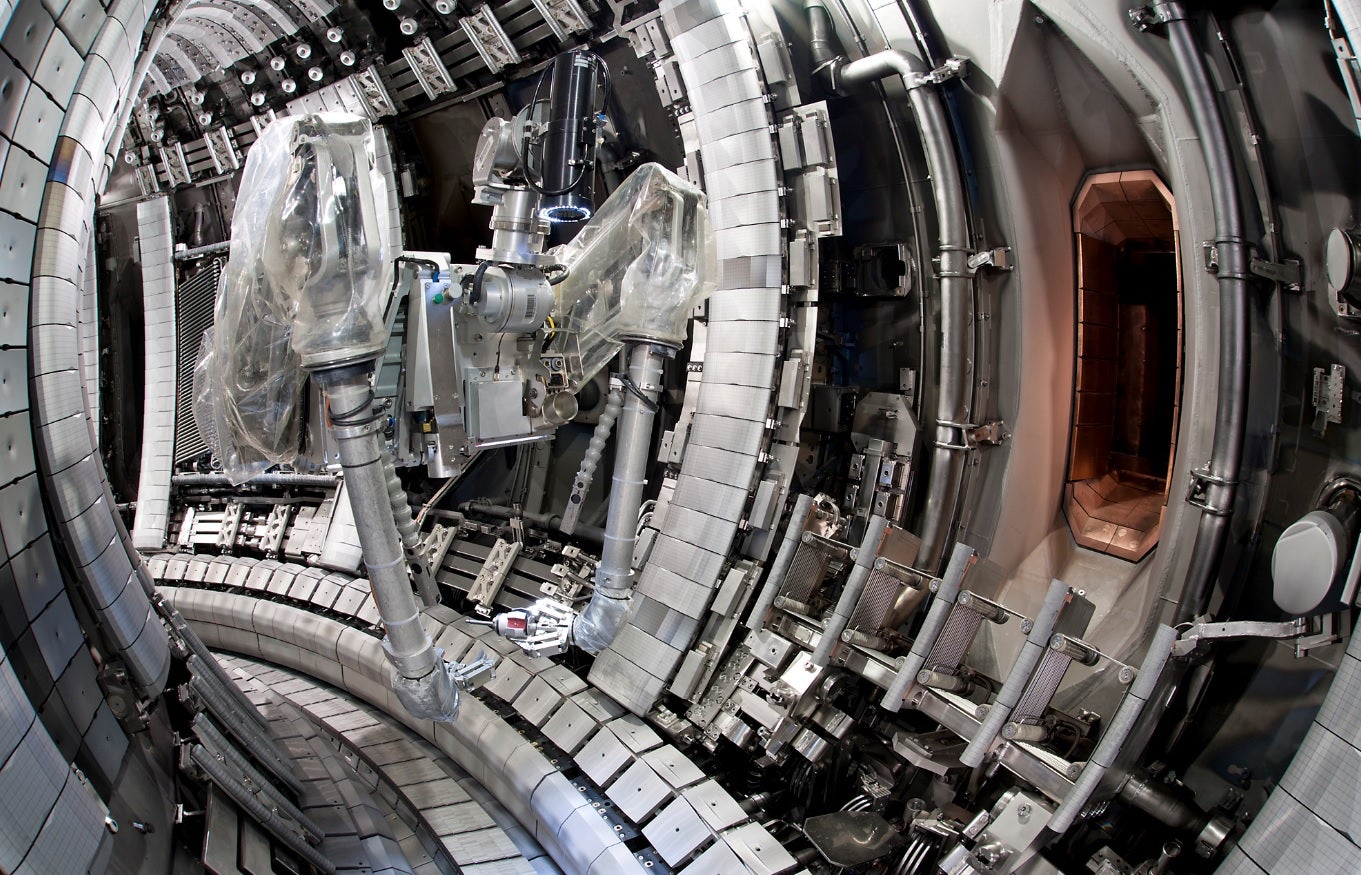

RB: LongOps will enable faster and safer decommissioning. Decommissioning legacy nuclear facilities are complex large-scale projects that take a long time to accomplish safely. The purpose of LongOps is to develop automated techniques that will use long-reach robotic arms to make decommissioning tasks quicker and more efficient, with no risk to human health. These can then be implemented at sites such as the Fukushima Dai-ichi reactors in Japan and at Sellafield in the UK.

SE: What are some of the problems previously encountered in this field when it was reliant on human rather than robotic labour?

RB: The primary use of robotics in decommissioning is to reduce the risk to which workers are exposed. Cleaning up nuclear sites can require thousands of person hours and often means working in hazardous and challenging environments. There are a number of situations where, owing to the degree of chemical and radioactive contamination and the very long half-lives of the radioactive materials involved, remote handling is the only feasible option.

Performing tasks manually in a high-radiation environment also results in additional costs for protective equipment and administration. Remotely-operated equipment can tolerate high radiation fields and its durability results in lower costs throughout the lifetime of the project. Plus, remote equipment is more mobile and can perform more complex tasks for longer periods of time.

Workers may need to participate in multiple training rehearsals before actually performing the task. Even though the operator of a remote system will need training to do the task effectively, the overall requirement is lower, therefore more time can actually be spent on the work itself – resulting in greater productivity.

SE: Can you tell me anything about fusion energy? What potential does it have as an energy source in the world, and what’s currently standing in the way of it taking off?

RB: Fusion has the potential to give the world an enormous new source of low-carbon electricity for the long term. It goes without saying that clean energy is one of the biggest challenges of our time, and fusion is a potential game-changer. The fuels are abundant around the globe, it is inherently safe and doesn’t emit greenhouse gases.

However, building fusion power plants is a complex task – we need to develop machines that can fuse atoms at temperatures hotter than the sun. We are now at the stage of moving up from experimental machines to designing large prototype power plants.

The UK has a project called STEP – Spherical Tokamak for Energy Production – which aims to create a prototype fusion power plant by the early 2040s. One of the challenges for such a plant will be maintenance, because there will be a need to use robotic devices to carry out the work instead of people. UKAEA is already working on these systems and LongOps will help take this research and development forward.

SE: What role will the UKAEA’s RACE facility play in this project?

RB: The UKAEA is leading the delivery of the LongOps programme, which is funded equally by UK Research and Innovation, the UK’s Nuclear Decommissioning Authority, and Japan’s Tokyo Electric Power Company.

UKAEA has many years of robotics experience through its RACE centre, based at Culham in Oxfordshire, UK. RACE will work with top universities and companies to develop solutions to cross-cutting challenges in areas such as improving the accuracy of control of long-reach robotic arms and developing better human interfaces for task planning and execution, enhanced with the latest technology in robotics and autonomous systems.

SE: What does the future hold for this technology?

RB: Many developments in other sectors, such as self-driving car technologies and artificial intelligence, have the potential to significantly improve on what we are doing with robots in the nuclear sector today. We are very excited about how these technologies can be used to make operations safer, faster, and cheaper, whilst improving the quality of working conditions for operators.