The Covid-19 pandemic, the fall in wholesale energy prices, the country’s gas and electricity use falling, the shortage of HGV drivers that led to huge queues at petrol stations – these events have led to crises, not only in the UK but elsewhere.

However, ahead of next month’s UN COP26 Conference and as governments around the globe plan to use green energy sources more, and reach net-zero by 2050, we speak to the co-founders of University of Oxford spin-out Brill Power. CEO Dr Christoph Birkl and CFO Carolyn Hicks explain their new “breakthrough” battery management system (BMS), which could transform the cost and performance of energy storage systems.

Sam Tabahriti (ST): Could you talk me through the process and initial idea behind this new BMS?

Dr Christoph Birkl (CB): The problem that our technology is tackling is the way that batteries at the moment are limited by performance and lifetime of some of their individual cells. In big battery systems that go into large scale stationary storage or electric vehicles, there can be thousands of individual single cells behaving quite similarly.

But over time, they will fade at different rates, and any one of these cells can end up limiting the performance of lifetime and even the safety of the whole battery system if it’s not controlled properly.

We were initially interested in what made batteries fail and why did they end up in the bin. We started at the small scale, and literally dumpster dived into the bins of the engineering and physics departments at Oxford to take out battery packs that were discarded. By testing them, we found that over 50% had more than 70% of their original storage capacity left. So that meant that they were still perfectly usable.

So, one thing that we really must avoid is for a technology like batteries, which could have this hugely beneficial renewable benefit, is to underutilise it. So that’s what really got us putting our mind to it – it is an engineering challenge. All you need is a smarter control system, because you can account for a lot of those differences that evolve over time.

In the batteries themselves with smarter controls, the problem that we’ve identified was the fact that the controls or the battery management system hasn’t really changed since it was first introduced in the 90s. It’s got very, very basic functionalities that provide a basic level of safety, and a basic function of balancing between cells.

ST: How does it fit into the grand scheme of tackling climate change?

Carolyn Hicks (CH): One of the things that we recognise from the outset is that providing solutions themselves have environmental impact. When we talk about using energy storage to support renewables, there is embedded energy expenditure to create batteries. You know there’s an impact all the way from mining in various parts of the world, all the way through to the manufacturing and delivery of the packs themselves.

And so that’s why we’re so motivated to make sure we’re getting the most out of the battery packs once they’re being built. We are just one component in a much larger scheme and system to reach net zero, but without being very smart about how we’re implementing renewable solutions, we might find ourselves on a much longer path towards net zero than we should be, if we’re not smart with what we do with what we have.

By focusing on the control and the reliability of the system, as opposed to just the battery cells themselves, we are able to innovate in this space where there hasn’t been that improvement as much as they should have been.

ST: What are the main benefits of this new BMS and how important is it to create batteries that are better and safer?

CB: We saw a big opportunity there, that’s how we came up with our new approach to battery management, which now makes sure that none of these individual cells can limit the performance lifetime or safety. We now avoid this huge amount of waste, and we can ensure that batteries can be a renewable technology.

Now it’s just a matter of making the most out of that technology, making sure that we don’t put in a bunch of batteries that have to be replaced after a few years because we didn’t develop them well enough, and we didn’t use all the engineering solutions that we have created to make the absolute most out of them.

I think that is really the goal right now, but you can’t afford failure of rolling this technology out at the moment because that would be disastrous on the path to net zero, and indeed fighting climate change, worldwide.

There is a lot of waste going on and our BMS is changing this. It is making sure that none of these individual cells are allowed to limit the performance lifetime or safety of the whole battery system. So that means we can extend battery life by up to 60% for an ageing battery, we’ve shown that we can increase the energy storage capacity by up to 129%.

That’s something that DNV GL (part of Det Norske Veritas group) tested, and ultimately, we can also make the system safer by making sure that if anything starts going wrong at the cell level, we can quickly identify and contain that.

ST: How will this transform the way we use energy at home and at work, and can you tell me more about whether there is a difference of operating costs in the shorter or longer term?

CB: If you’re installing a solar photovoltaic array, at home or your business, you would expect the system to easily live 15-20 years. But if you complemented that with energy storage, the maximum warranties you would get at the moment would be about 10 years.

There is a clear mismatch between how long your storage lives versus your photovoltaics, and we have to fill that gap, or else you would have to replace the batteries. They’re very expensive components so nobody would want to buy a new battery just to keep the PV going.

So as a user, you will see the benefits in your total cost of ownership; you’ll buy one battery, instead of replacing that battery in the future. That goes for both home and business use. Another way you’ll see the benefits of our technology will be in the fact that the overall system can be cheaper and more reliable.

I think those are the big takeaways for the end user specifically, they are lower total cost of ownership. They are a simpler system and lower system cost, and they are higher reliability and redundancy and availability of power for the end user.

ST: Lastly, why can a small group of people from the university come up with an innovation that the whole industry has been trying to solve?

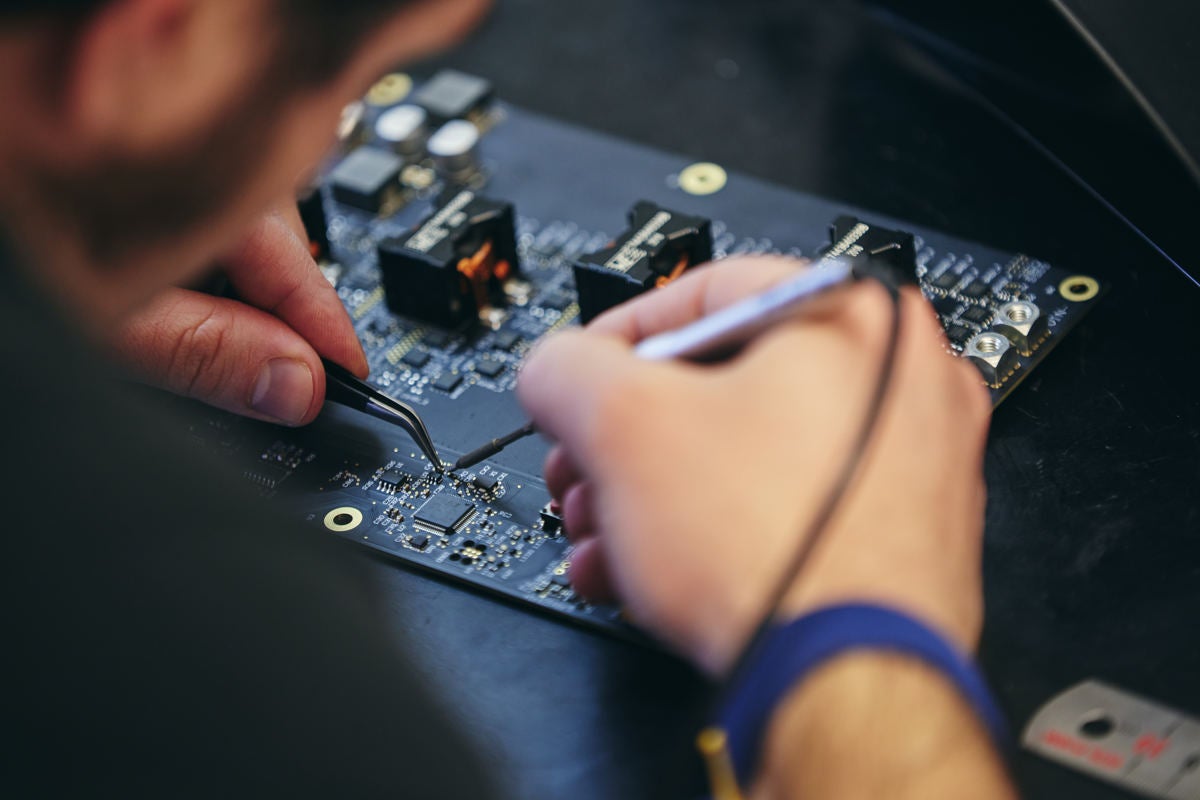

CH: There was a unique combination of skill sets that started Brill Power, and that was Chris understanding how batteries degrade, Adrian understanding how batteries are modelled, and Damien understanding the power electronics. That type of innovation usually lives in different departments in big organisations but at Brill Power that sort of thinking and developing innovations and ideas, sometimes even at the pub, has gotten us to a really great idea that can be applied across platforms.