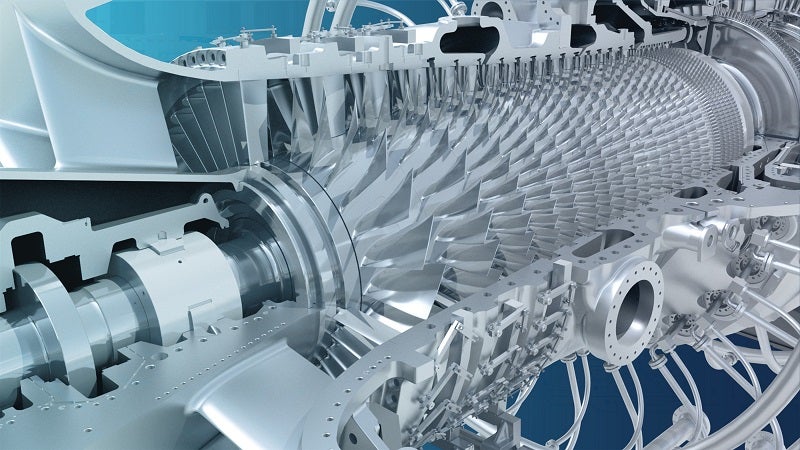

On Monday 26 March General Electric Power (GE) revealed the GT26 HE upgrade for its gas turbines. The update will use GE and Alstom technology to increase the power of each turbine from 15MW to 55MW, and make $5m in fuel savings each year due to baseload and part-load efficiency. The turbines will be used at German company Uniper’s power plant in Enfield, North London when completed in June 2020.

At the launch event in London, GE General Manager Amit Kulkarni and GT26 Product Manager Simone Serges explained the challenges and the benefits of the new upgrade.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Jack Unwin (JU): How long has this project been in development?

Amit Kulkarni (AK): We started working on this in 2016. We do multi-generation product planning for every product we develop by looking at installed base, the markets, where things are moving and what drives value for customers in the next five to ten years.

When we saw where the GT26 was, we realised that there was an opportunity for a significant upgrade. The scope of the project evolved over time, and brought together the research and development, and engineering philosophies of GE and Alstom.

To me that is really what is fascinating about this, some of the complexity and technology that the GT26, 24 and the legacy that the Alstom machines brought was fascinating.

JU: What were the key challenges that you faced with this project?

AK: I think developing any technology is always going to be challenging, as you’re trying to solve one issue but then that can lead you in a totally different direction.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataHow do you find the right balance of getting rid of issues without changing the technology too much, because we still want to be able to run the machine the way we originally planned? It takes the interaction of engineering and design to make that happen, because you try to change one thing and sometimes that means something else goes another way.

Simone Serges (SS): Technical issues have to be viewed in relation to an evolving market. It takes a while to develop a certain technology, and in the meantime the market is changing at a fast pace. How do we keep this signal from the market and integrate that feedback to help with our challenges on the technical side, as challenges occur in real time.

JU: To stick with the market, who would you say are your competitors in this field?

AK: Ansaldo. They are somebody we look at as another original equipment manufacturer (OEM) that has the technology and the engineering background to develop upgrades for these machines.

But we try to stay ahead of that competition curve, we look at what upgrades we foresee from other OEMs and we try to make sure we are two steps ahead.

JU: What environmental considerations were there for the GT26 HE upgrade?

AK: We want to make sure that we are emissions complaint with every gas turbine we have and every upgrade we make.

We think of emissions compliance as what we call ‘hygiene factor’, it’s the base mark. How do you maintain that compliance and still be able to tune the machine in ways that the customers need? If they want to turn it down even more can we do that and stay emissions compliant?

So for us every product is emissions compliant and the design work is always done with that target in mind. If there are regions that ask for even lower emissions, we have products that we develop to go do that.

SS: On the combustor side, there’s been a lot of effort put in to try to keep the emissions within the limits whilst still providing more efficiency and power output. That was a huge challenge! An example of this was the complete re-design of the combustion system to allow for a better mixing between air and gas

JU: Do you think gas power and renewables can work together or are they conflicting?

AK: I’ve never thought of it as a conflict to be honest. Renewable additions have been enormous in the past few years, this will continue to happen.

On the other side of the equation, coal is coming down. We are going to lose 400GW in the next 15-20 years, and nuclear capacity is falling. How do you make up for that capacity?

Renewables mean intermittency in power generation. When the wind blows you’re producing power, but when the wind stops blowing you’re not. The same is true of solar, the sun stops shining and you stop producing power.

We need to figure out a way to complement renewables, and that’s where gas power comes in. I don’t think there is a better way to complement the energy mix than having thermal gas power coupled with renewables.

JU: What changes have you seen in GE since you started?

AK: We say in GE change is constant. I’ve been there a long time and I’ve worked in different parts of the company, which has allowed me to experience how a business operates. And GE is always changing, we’ve changed our portfolio and that’s what keeps it fascinating.

SS: I have more of an outsider’s perspective; I came from Alstom initially when we were acquired by GE. My view is that GE is a much more agile company with a focus on what’s happening in the market, that’s the main thing.

AK: One other thing I will say, there is a lot of talk and a lot of things written about GE and GE Power but when I think of the 7000 gas turbines worldwide delivering half of the world’s electricity, powering people’s homes, everything else becomes irrelevant. ,

We light up homes in Southeast Asia, Africa, and Bangladesh, where people are still starved of power. To me, that’s what drives us as a company and that’s why we think there is another way for gas power, I don’t think it will go away too soon.