TPI Composites has developed a system for wind turbine blade fabrication, utilizing laser projection and synchronized layup segments in mold sections. The system automates composite structure production, setting a pace for operators to ensure tasks are completed within allotted timeframes. Projection devices visually depict layup segment boundaries on the mold. GlobalData’s report on TPI Composites gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on TPI Composites, Turbine components 3D Printing was a key innovation area identified from patents. TPI Composites's grant share as of March 2024 was 48%. Grant share is based on the ratio of number of grants to total number of patents.

Automated system for wind turbine blade fabrication

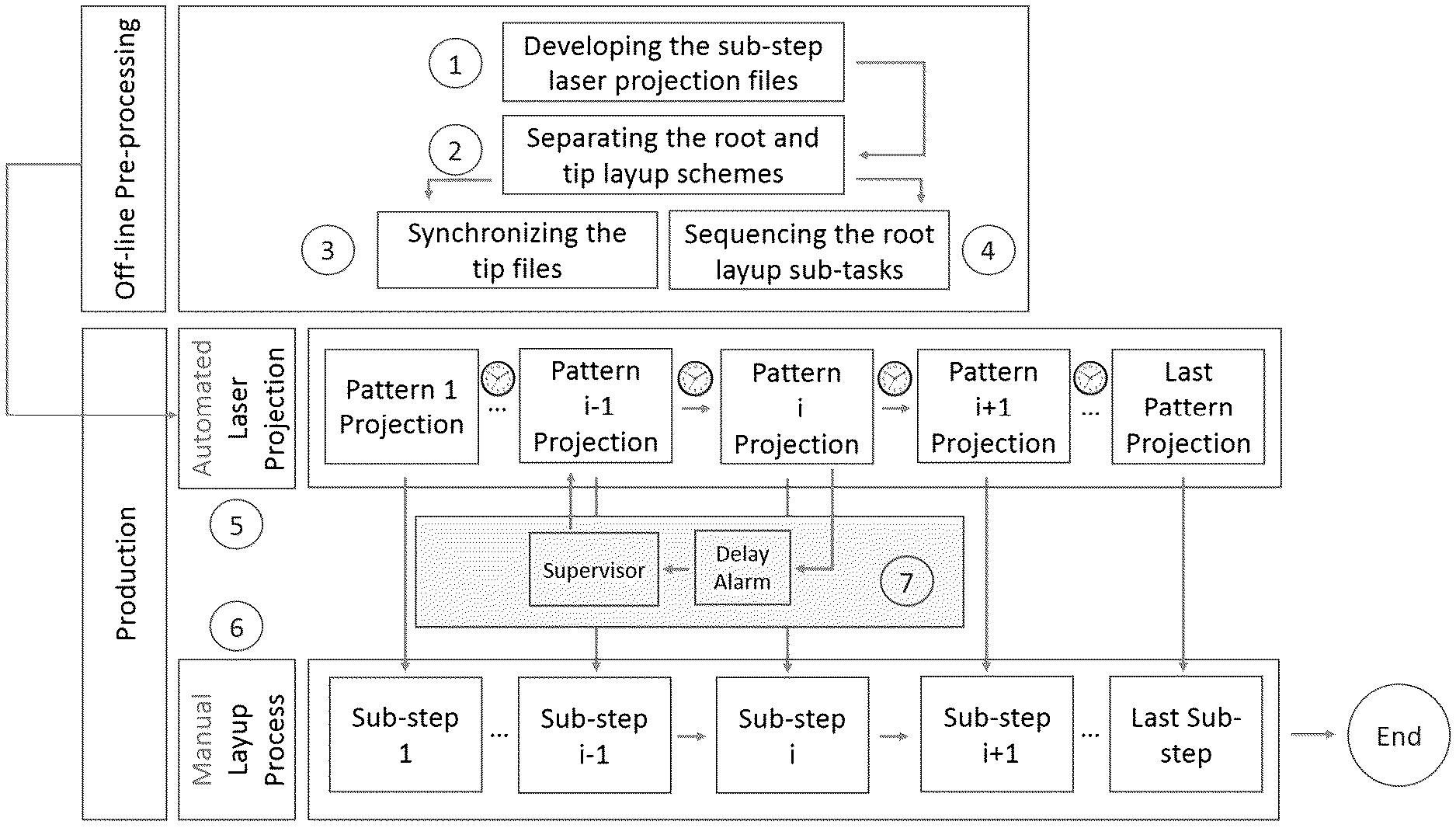

A recently granted patent (Publication Number: US11931976B2) discloses a system and method for fabricating composite structures, particularly wind turbine blades, using a novel approach. The system includes a mold with a contoured surface, a layup projection generator, and projection devices to visually depict layup segments onto different sections of the mold. The layup projection generator defines mold sections, identifies dimensions for layup segments, and specifies the sequence of layup segments synchronized within different sections of the mold. A layup delivery mechanism is also included to deliver layup segments to the mold sections based on the visual projections.

The method involves providing a mold, a layup projection generator, and projecting boundaries of layup segments onto different sections of the mold in a synchronized manner. The method includes identifying a predetermined time interval scheme for layup segments, projecting boundaries and indication codes onto the mold sections, and delivering layup segments accordingly. The system and method are specifically designed for manufacturing wind turbine blades, with different sections of the mold representing the root and tip portions of the blade. The cycle time for manufacturing the composite structure is defined based on the sequence of layup segments and the predetermined time interval scheme. Additionally, the system includes features such as unique boundary projections for each layup segment and alerts for any delays in delivering layup segments. The layup projection generator is positioned above the mold and configured for relative movement, enhancing the efficiency and accuracy of the fabrication process.

To know more about GlobalData’s detailed insights on TPI Composites, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.