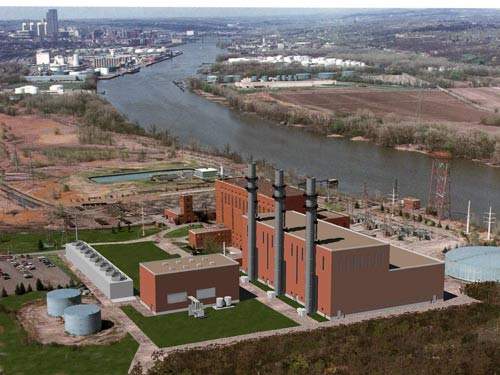

A second power plant was completed at the Bethlehem Energy Center (BEC), replacing the existing Albany Steam Station in Bethlehem, New York. The plant is a combined-cycle gas turbine (CCGT) facility that uses GE Model 7 gas turbines and a steam turbine. It has lower emissions than its oil and natural gas-fired predecessor and uses a small amount of low sulphur distillate oil, as well as the cleaner natural gas.

In May 2000, PSEG Power New York acquired the original Albany Steam Station from Niagara Mohawk Power Company. The gas-fired power plant is located on the west bank of the Hudson River in Bethlehem, New York, approximately three miles south of Albany.

Albany steam power station and the Bethlehem Energy Center

Albany Steam Power Station first began operations in 1952 as a coal-fired station and was converted to oil in 1970. It was further modified in 1981 for natural gas and became a 400MW oil and natural gas-fired power plant.

Having acquired the Albany Steam Station, PSEG Power New York carried out the plans originated by Niagara Mohawk in 1998 to build the new BEC power plant.

The BEC is a 750MW, combined-cycle power plant. Once the BEC is in operation, the Albany Steam Station will be closed.

BEC is the first project in the Hudson Valley to replace an older, existing power plant. It has almost doubled the output of Albany while dramatically reducing air emissions and use of the Hudson River water. The Albany Steam Station was closed in February 2005.

The Bethlehem Energy Centre is a natural gas-fired combustion turbine generation plant. Instead of using a steam boiler to make steam to drive the turbine, the process involves gas-fired combustion turbines producing electricity directly. The BEC uses existing electric transmission lines and gas delivery pipelines.

Natural gas or oil and CCGT technology

Although it does generate CO₂ emissions, natural gas is the cleanest fossil fuel available to produce electricity. As a backup, PSEG Power has designed BEC to use low-sulfur distillate oil as a secondary fuel.

The BEC will use combined-cycle technology – the most efficient of the fossil-fuelled electricity-generating technologies. This efficient process will enable the BEC to use 36% less fuel than the Albany Steam Station to generate each kilowatt-hour of electricity. Burning less fuel to generate electricity translates into reduced emissions of air pollutants.

BEC approval and construction

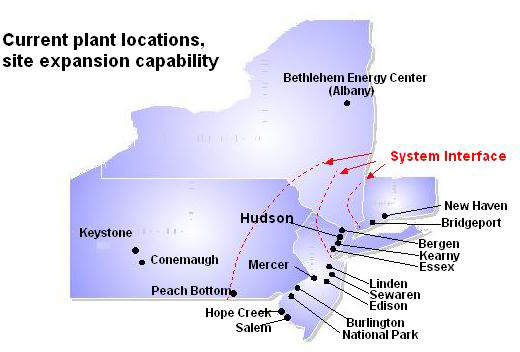

In June 2001, the New York Independent System Operator (NY ISO) approved the transmission plan for the BEC. Construction began in June 2002. The completion date was revised in October 2002 and was set for the second quarter of 2005.

The BEC generates 50% less waste heat than the Albany Steam Station and has reduced air emissions by at least 95%.

The Albany Steam Station draws water from a river, uses it once in the generation of electricity, and then sends the water back to the river (once-through cooling). The BEC will be using an advanced closed-cycle cooling system that recycles water from the Hudson River, therefore drawing 99% less water from the Hudson River than the Albany.

The BEC has cut emissions of smog-causing nitrogen oxide by 90% and reduced sulphur dioxide emissions, the pollutant that causes acid rain, by 94%.

When BEC operates on its secondary fuel, it will be using distillate oil with low sulphur content. This ensures that the BEC is amongst the cleanest power plants in the state.

Strong relationships with suppliers and contractors

PSEG Power New York was purchasing building materials from local suppliers. Power generated by the BEC will be sold wholesale through the regional power grid managed by the New York Independent System Operator (ISO). GE Power Systems is supplying the Model 7 and steam turbines.

PSEG Power built strong relationships with a team of key contractors and suppliers. Other potential contractors included SM Electric (electrical contracting); J. Fletcher Creamer (civil contracting); Foster Wheeler Energy Corporation (heat recovery steam generators); Hamon, Inc. (cooling towers); Turtle & Hughes (electrical material supplies); Holtec International (condensers); and Duke / Fluor Daniel (engineering, procurement and construction services).